High efficient LED

A technology of light-emitting diodes and light-emitting diodes, applied in optics, electric light sources, optical components, etc., can solve the problems of large size, heavy weight, and low light extraction efficiency of conical condensing lenses, so as to improve the effective luminous efficiency, high Color rendering index, high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

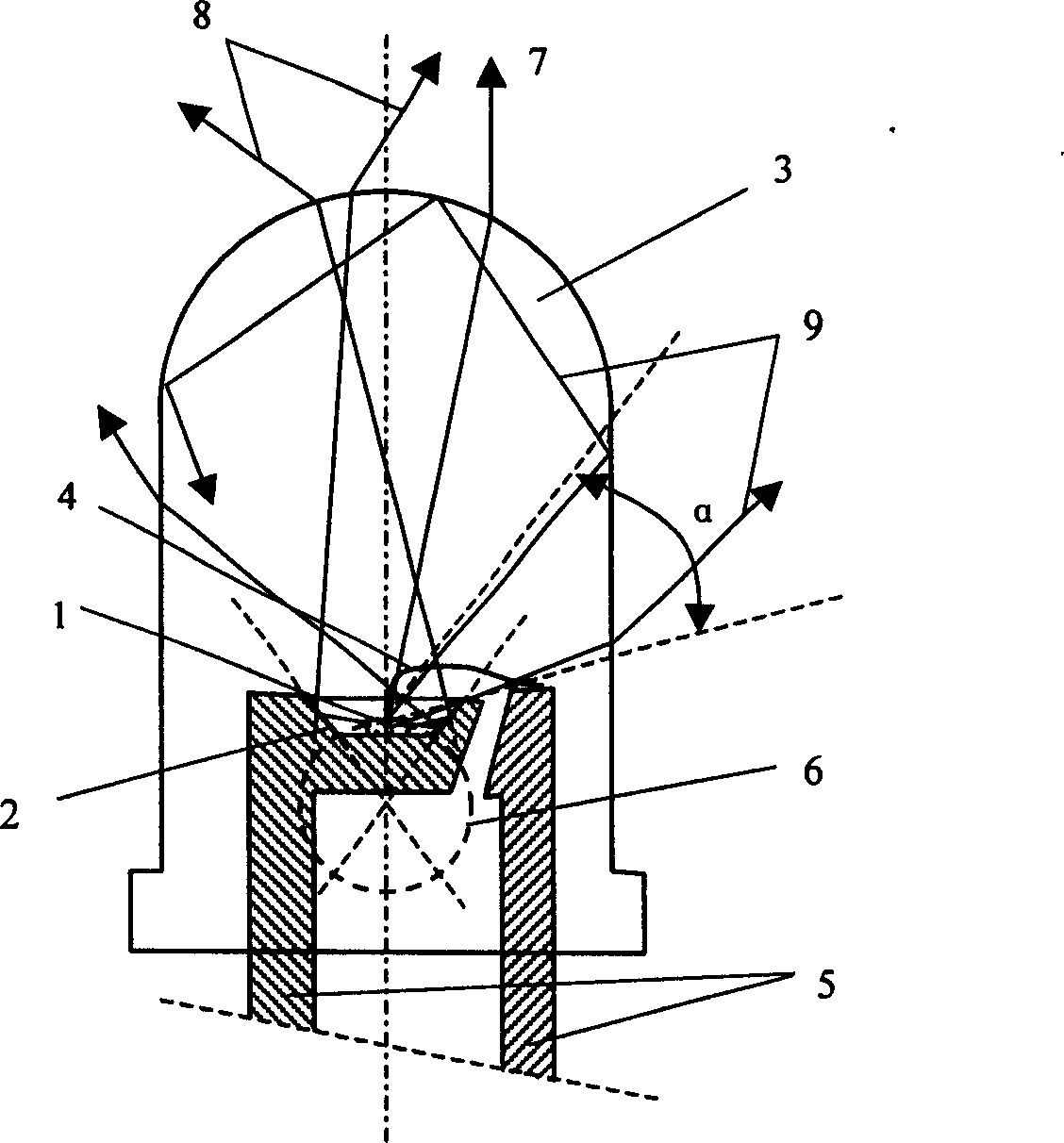

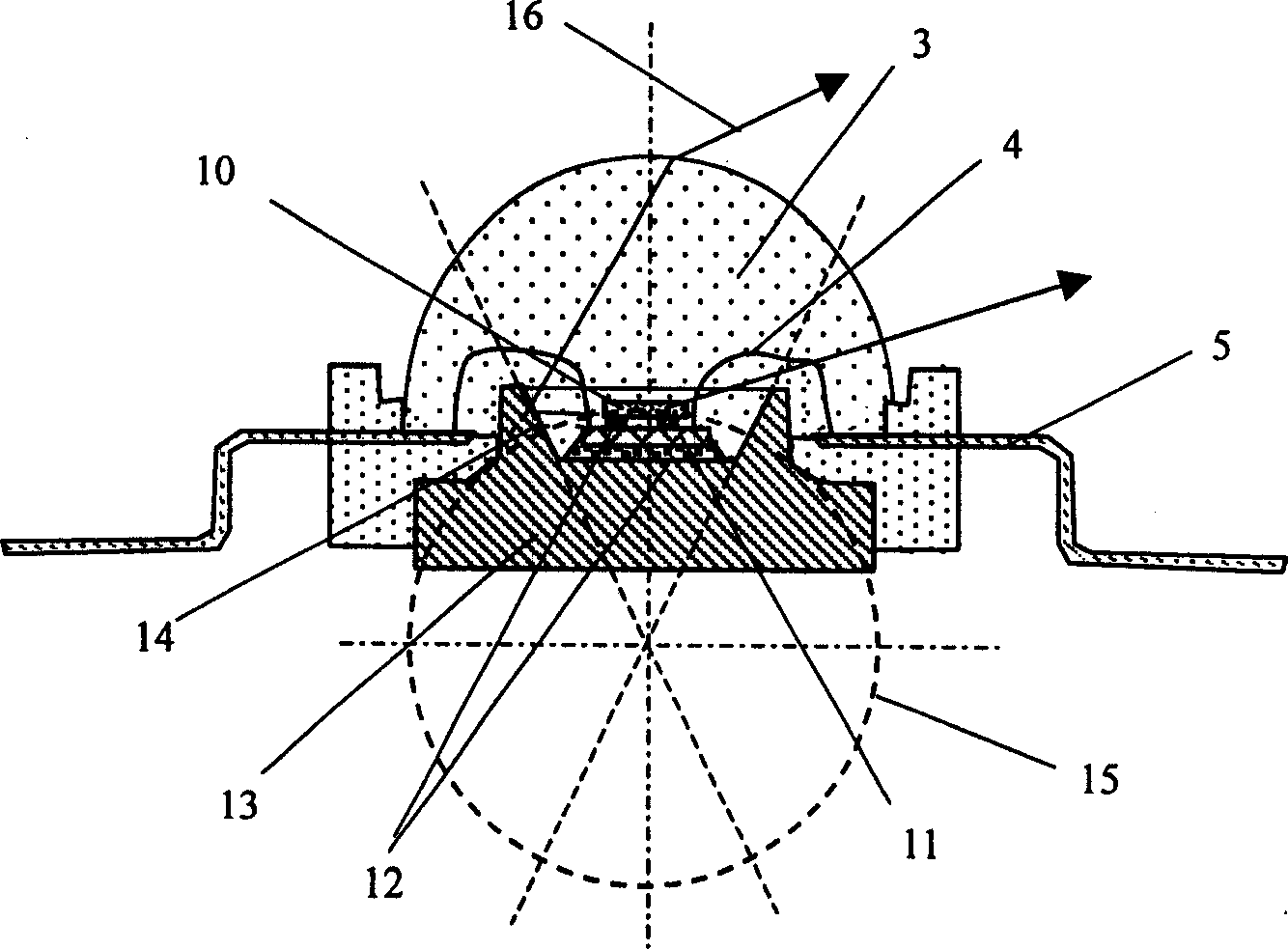

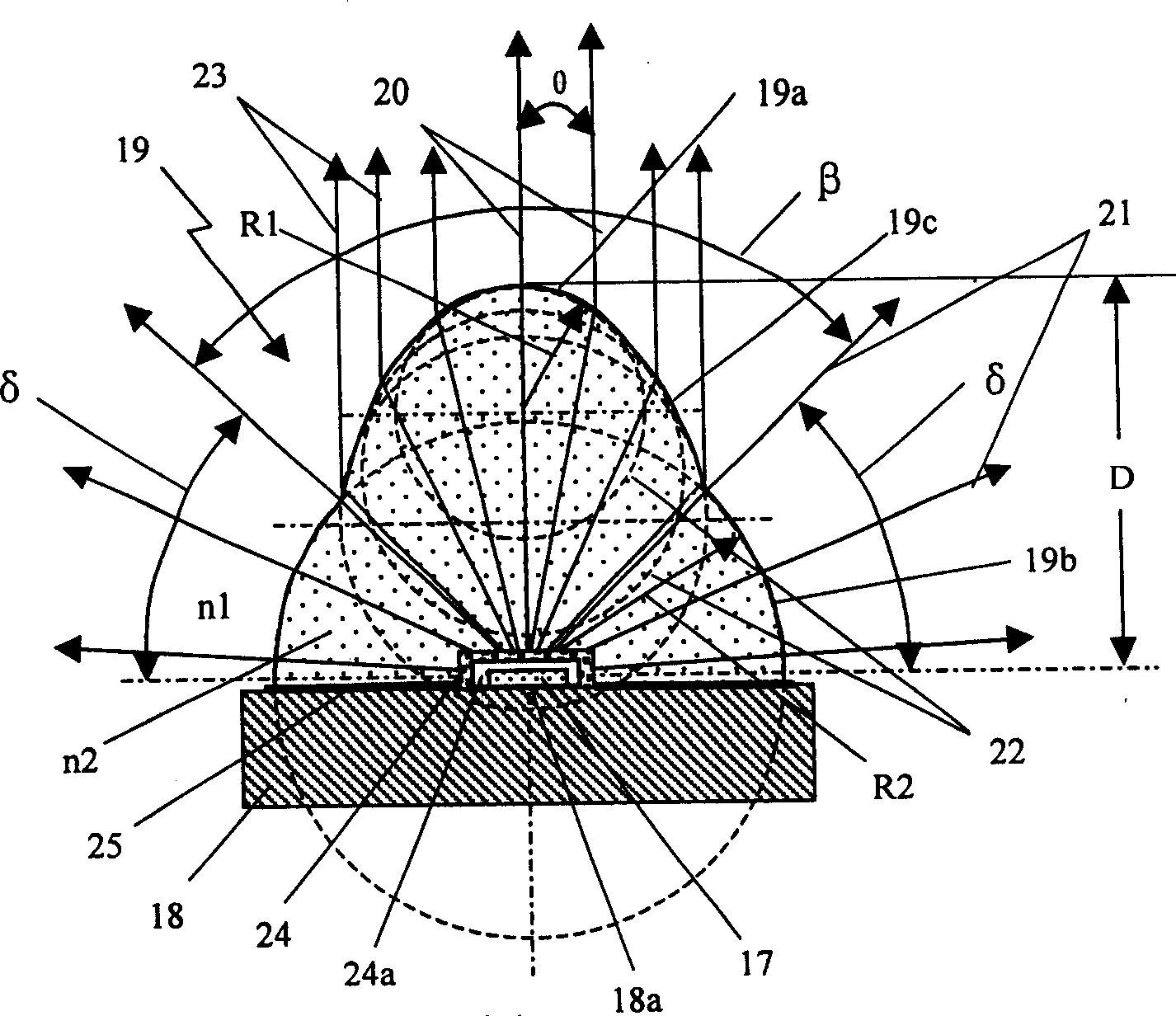

[0022] The markings in the accompanying drawings are as follows:

[0023] 1-chip 2-reflector bowl 3-lens

[0024] 4-Electrical connection line 5-Leader line 6-Virtual image

[0025] 7-Output Ray 8-Output Ray 9-Output Ray

[0026] 10-chip 11-silicon substrate 12-solder or thermal paste

[0027] 13-Metal Base 14-Light Reflecting Bowl 15-Virtual Image

[0028] 16-output light 17-chip 18-metal base

[0029] 18a-Metal base plane 18b-Metal base mesa 18c-Metal base cone

[0030] 18d-Metal base multi-mesa 18e-Metal base cone 19-Lens

[0031] 19a - Lens top 19b - Bottom lens 19c - Lens middle part

[0032] 19d-Lens fixing foot 20-Output light 21-Output light

[0033] 22- Lens transition surface 23- Output light 23- Output light after reflection

[0034] 24-luminescent powder layer 24a-translucent medium layer 25-medium layer

[0035] 26-Output light 27-Insulation layer 28-Conductive layer

[0036] 29-Screw 30-Medium Layer 31-Light Emitting Diode

[0037] 32-light reflector 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com