Method for making large area uniform film or long superconducting wire and its apparatus

A superconducting wire, large-area technology, applied in the usage of superconducting elements, manufacturing/processing of superconducting devices, superconducting/high-conducting conductors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Deposition of large-area YBCO superconducting thin film by using this rotary heating heat treatment furnace device

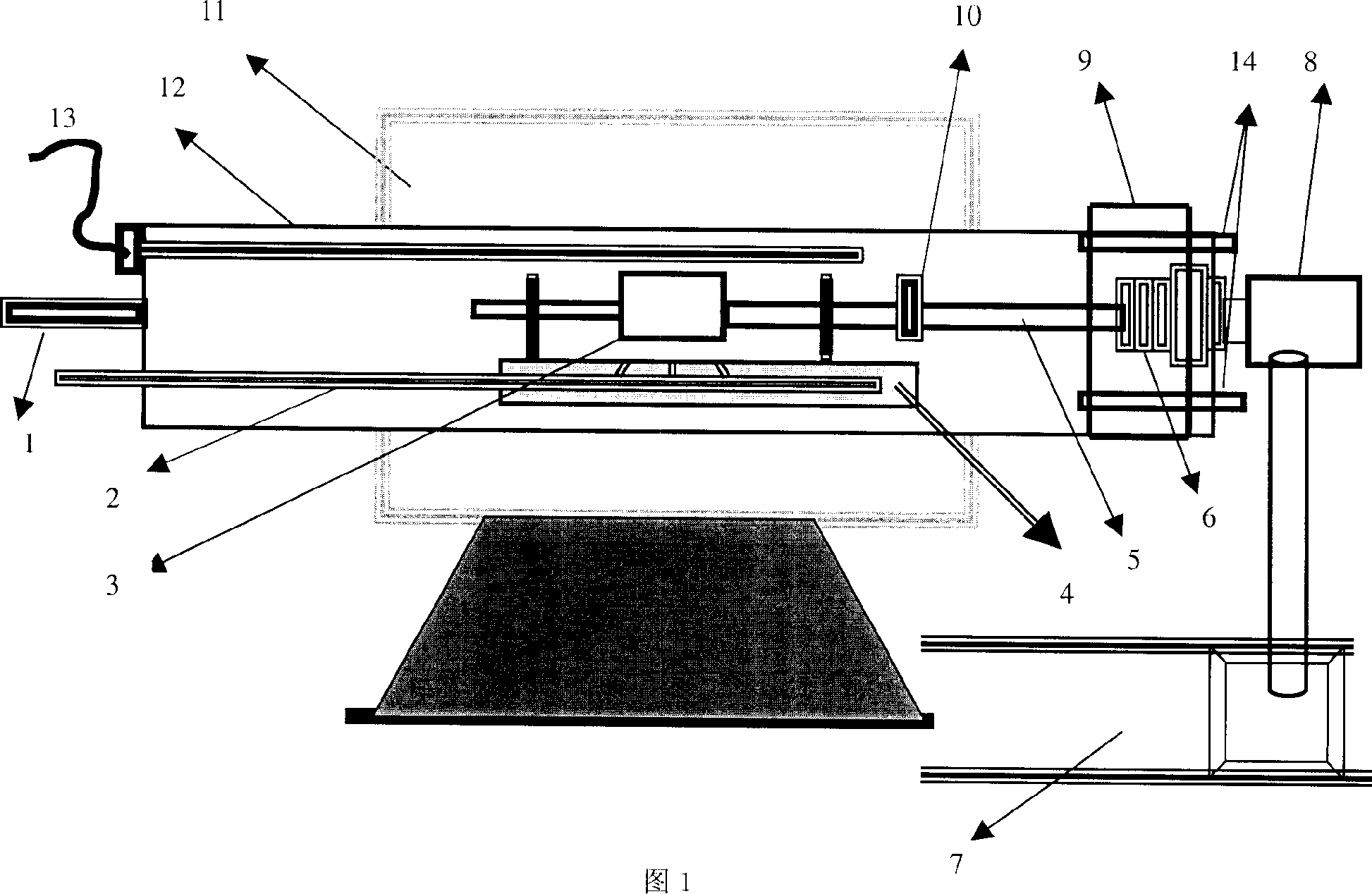

[0057] The schematic diagram of the reaction chamber is shown in Figure 1.

[0058] In the experiment, LaAlO with a size of 30mm×30mm was used 3 (100) Single crystal substrate, YBCO film was deposited by Wang Sansheng, Wang Lin, Du Peng, Chen Sheng, Han Zhenghe. Chinese Journal of Nonferrous Metals, 11 (3) 2004: 85-89 described TFA-MOD process spin coating. Put the coated sample in the sheet sample holder (3), open the metal flange rotary sealing device (9), pass the sample holder (3) through the metal interface (6), the rotating shaft (5), the connecting shaft ( 10), fixed on the sample holder (4), move along the motor track (7), move the metal flange to rotate the sealing device (9), and tighten the flange. Set the rotational speed of the speed-regulating motor (8) to 10 rpm to drive the sample to rotate. Set the heat treatment process curve for the...

Embodiment 2

[0064] Preparation of YBCO long superconducting wire by using this rotary heating heat treatment furnace

[0065] Schematic diagram of the setup of the reaction chamber 1.

[0066] In the experiment, CeO with a width of 10mm and a length of 10m was used 2 / YSZ / Hastealloy flexible substrate, YBCO film adopts dip coating process, the molar concentration of YBCO colloid is 1.8mol / L, and the pulling speed used is 50mm / min. Put the coated sample in the spiral tube type long wire sample holder (3), open the metal flange rotary sealing device (9), and pass the sample holder (3) through the metal interface (6), the rotating shaft (5), The connecting shaft (10) is fixed on the sample support (4), moves along the motor track (7), moves the metal flange to rotate the sealing device (9), and tightens the flange. Set the rotational speed of the speed-regulating motor (8) to 10 rpm to drive the sample to rotate. Set the heat treatment process curve for the heating furnace body (11), star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com