Ultra-small DC-DC module power and making method thereof

A modular power supply, ultra-small technology, applied in the direction of electrical components, electrical equipment structural parts, and conversion equipment without intermediate conversion to AC, it can solve the problems of different levels of product awareness, reduce the efficiency of transformer use, and can not meet the needs, etc., to achieve Satisfy the effect of small space layout, improve production efficiency and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

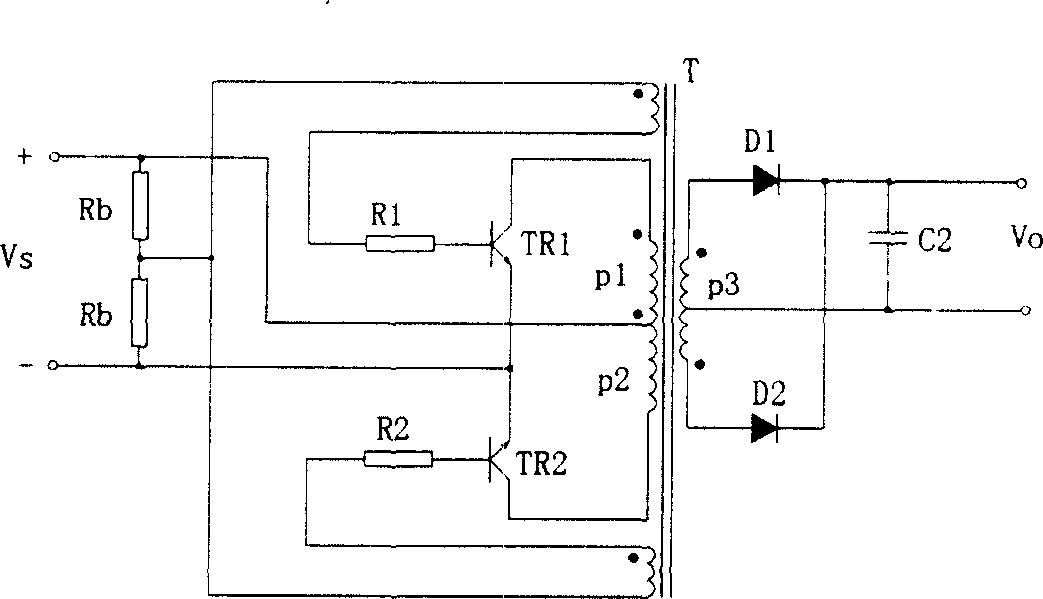

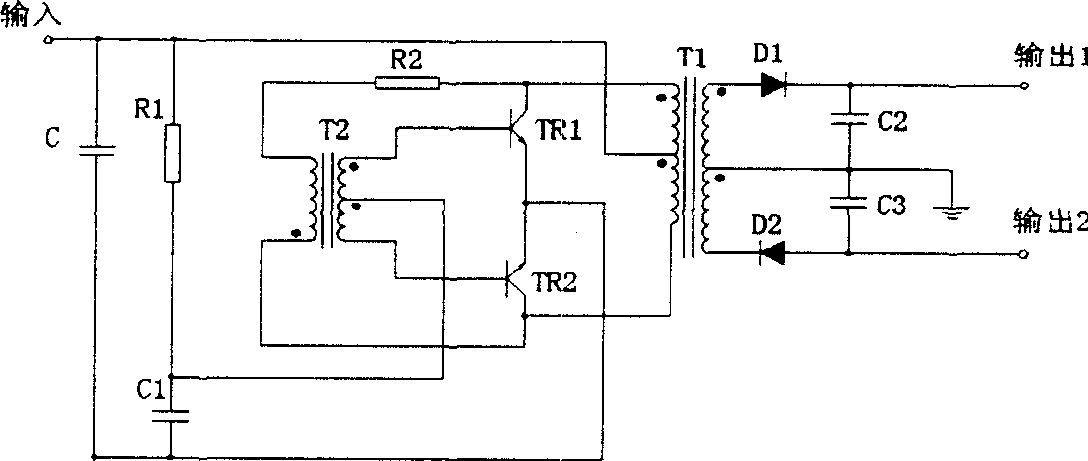

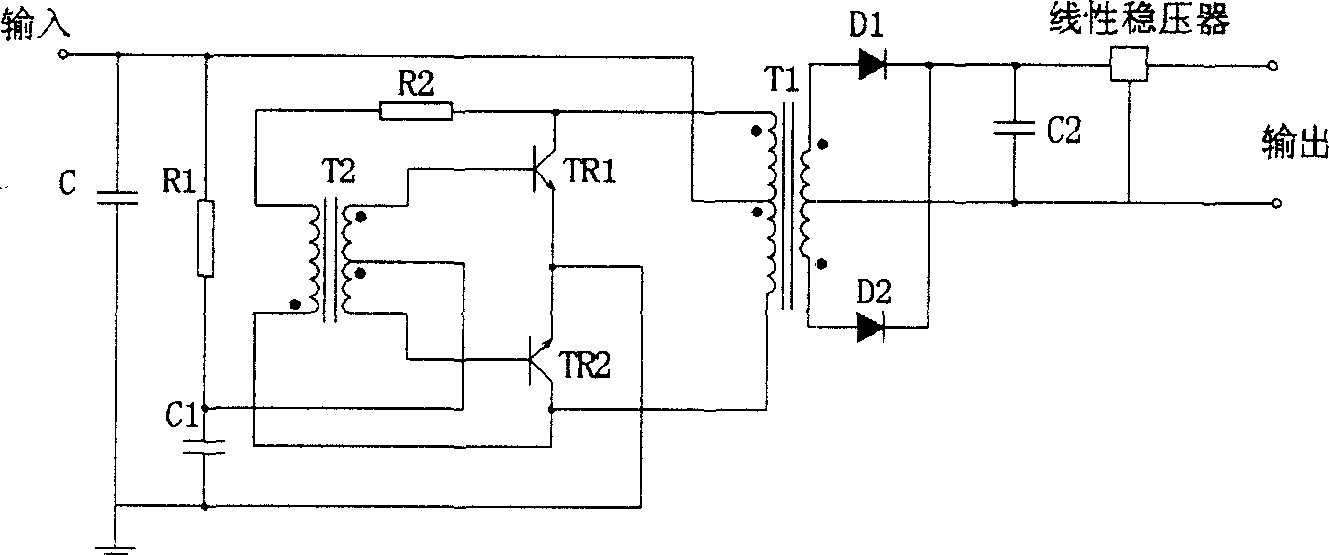

[0014] Such as Figure 2~3 As shown, the module power supply circuit is a Jensen circuit composed of an oscillation transformer, a power output transformer and a pair of push-pull transistors. Transformer, and a soft start circuit composed of resistor R1 and capacitor C1 is connected to the input end of the circuit, and the output is a dual unregulated output. When making, first paste the electronic components 3 to the corresponding pad positions in each frame unit 5 on the lead frame according to this circuit, and then weld the input and output terminals of each winding on the toroidal transformer 2 to the corresponding terminals in the frame unit Above, the toroidal core of the transformer is stacked on the lead frame with the components attached. After the entire lead frame is assembled, the injection molding process is completed through mechanical equipment, and the plastic injection molding is used to form it, and the products on the lead frame are cut and separated to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com