Process for producing theanine

一种制造方法、茶氨酸的技术,应用在制造茶氨酸领域,能够解决茶氨酸精制麻烦等问题,达到有利于工业生产、高效制造、生产简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

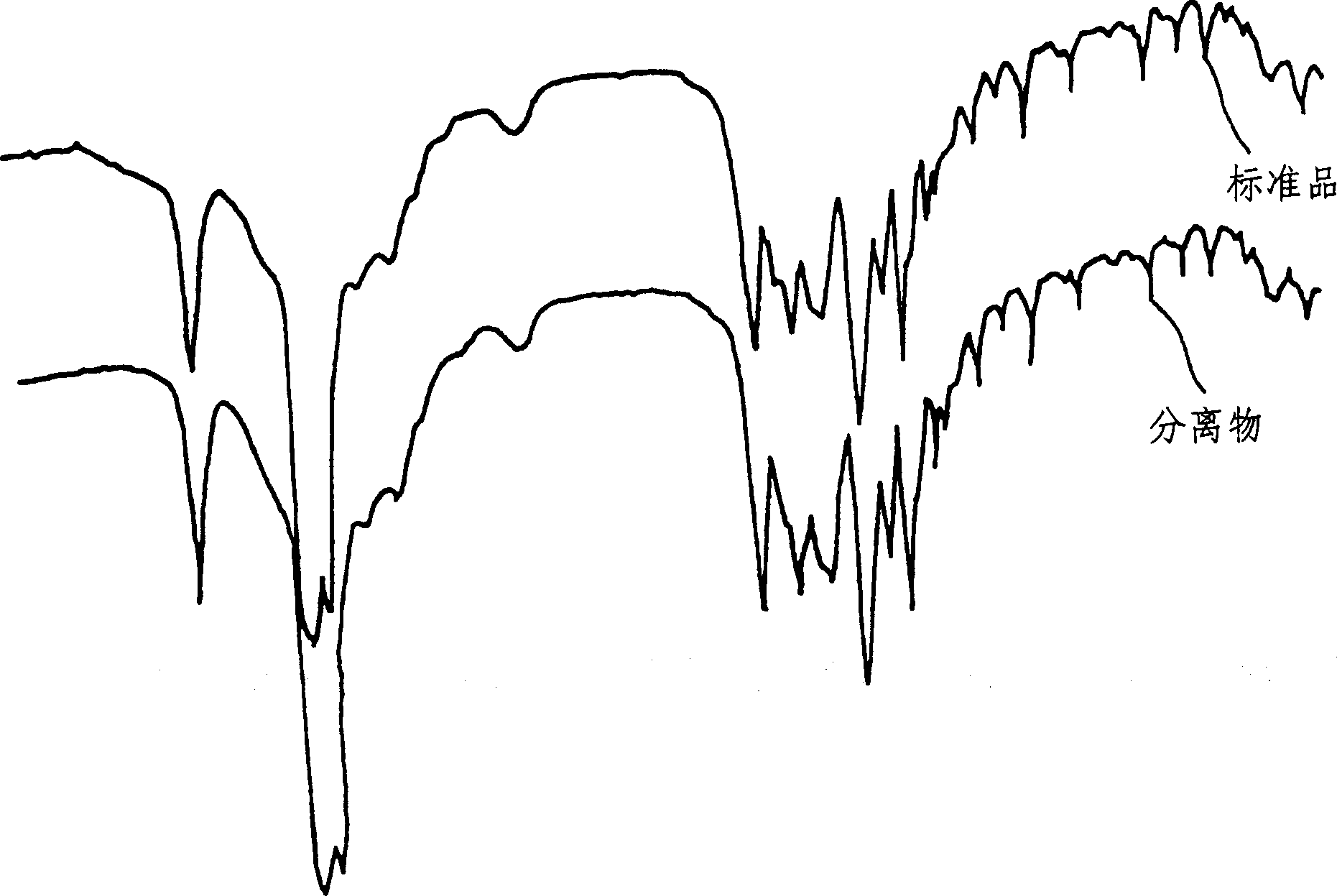

Image

Examples

Embodiment 1

[0017] Example 1 Isolation of Theanine Nutritive Bacteria (utilizing bacteria)

[0018] The soil from Shiga Prefecture and Kyoto Prefecture in Japan was used to prepare a soil suspension, and a selective medium with theanine as a carbon source was used, in which 0.5% theanine, 0.03% yeast extract, and KH 2 PO 4 0.05%, K 2 HPO 4 0.05%, MgSO 4 ·7H 2 O 0.03%, pH 7, subcultured for 3 times, and isolated 100 strains of theanine-trophic bacteria.

Embodiment 2

[0019] The preparation of embodiment 2 cell-free extract

[0020] In 1 liter of the selection medium of Example 1, 100 strains of theanine-trophic bacteria were respectively cultured at 30° C. for 20 hours. Then the bacterial cells were collected and washed, suspended in 50 ml of 30 mM potassium phosphate buffer (pH 7.0), and ultrasonically disrupted at 5° C. to 20° C. to obtain a cell-free extract.

Embodiment 3

[0021] Embodiment 3 enzyme reaction

[0022] Use the cell-free extract of embodiment 2, in the 100mM boric acid buffer (Na 2 B 4 o 7 -NaOH, pH 11), theanine was synthesized by performing an enzyme reaction at 30°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com