Electrode for lithium secondary cell and lithium secondary cell thereof

A lithium secondary battery and electrode technology, which is applied in the direction of secondary batteries, electrode carriers/current collectors, active material electrodes, etc., can solve the problems of large expansion and contraction of active materials, reduction of current collection, and detachment of active materials, and achieve good Effects of charge-discharge cycle characteristics and good current collection properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

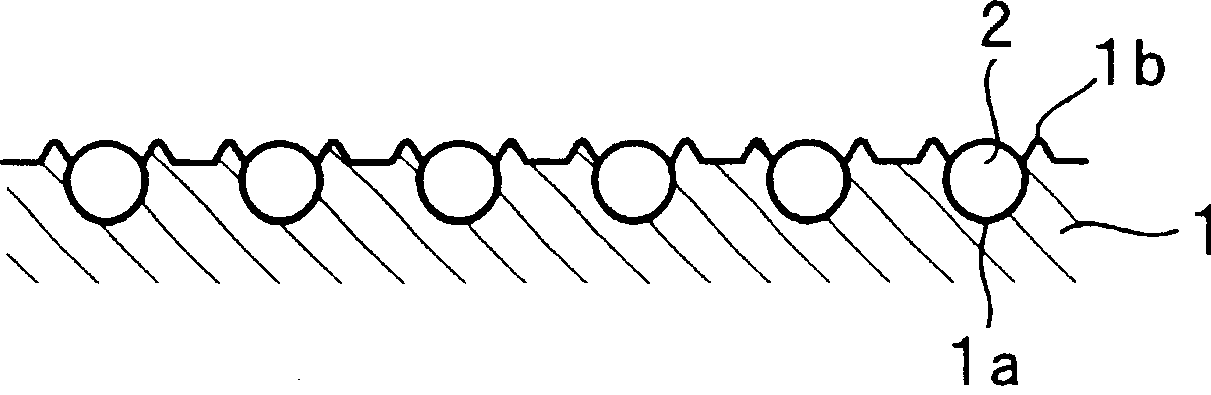

[0065] [Fabrication of electrodes using silicon as the active material by the cold jet method]

[0066] As the active material particles, crystalline silicon particles (average particle size: 2.5 μm) are used, and electrolytic copper foil (thickness: 35 μm, arithmetic average roughness Ra: 1.46 μm) is used as the current collector, and the silicon particles are impacted by the cold jet method. On the glossy side opposite to the roughened surface of the electrolytic copper foil, electrodes were produced. Specifically, using Figure 21 The cold-jet setup shown, with fabricated electrodes. Such as Figure 21As shown, a current collector 1 made of electrolytic copper foil was wound on a support plate 7 made of a copper plate with a thickness of 2 mm, and both ends were fixed with clips 6 . The current collector 1 is wound so that the glossy surface of the electrodeposited copper foil faces outward. The support plate 7 is used to prevent the current collector 1 from breaking du...

Embodiment 2

[0106] [Fabrication of electrodes using silicon as an active material by the cold jet method]

[0107] In order to make the silicon particles adhere to the rough surface side of the electrolytic copper foil, except that the rough surface of the copper foil is rolled on the support plate, the rest are the same as in Example 1, and the silicon particles are attached to the collector by the cold jet method. On the electric body, make electrodes.

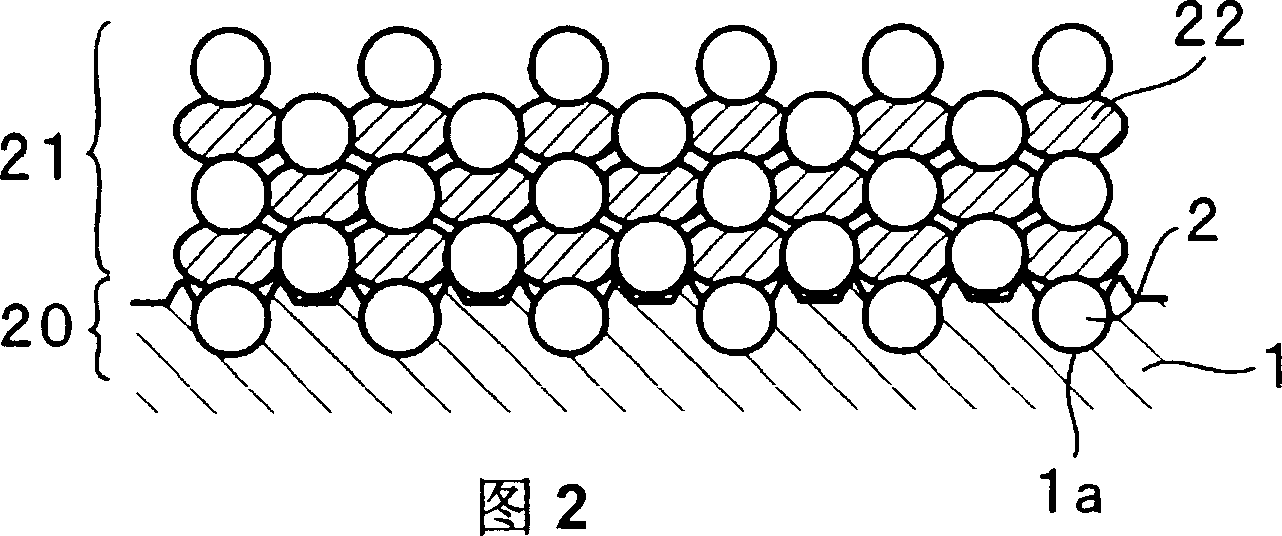

[0108] Also in the electrode obtained in this example, the silicon particles were very strongly bonded to the current collector. Figure 9 and Figure 10 This is a cross-sectional view of the cross-section of the obtained electrode observed with FIB-SIM. From Figure 9 and Figure 10 It can be seen that silicon particles adhere along the asperities of the current collector. In the comparison between the protrusions and the recesses among the irregularities on the surface of the current collector, it is considered that more silicon ...

Embodiment 3

[0196] [Making electrodes using a mixture of silicon particles and tin particles by the cold jet method]

[0197] As described above, in Examples 1 and 2 in which only silicon particles were used as active material particles, it is considered that the silicon particles are accumulated in one layer on the copper foil, that is, the accumulation thickness is only the size of one silicon particle. This is considered to be because in the cold jet method, bonding between silicon particles is difficult to occur, and after the surface of the copper foil is actually covered with silicon particles, the newly impacted silicon particles fall off without adhering to the silicon particles. Therefore, by accumulating only one particle in the thickness direction, the amount of the active material attached to the current collector can be controlled by adjusting the particle diameter of the active material particle.

[0198] In addition, as other methods of adjusting the amount of the attached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com