Fluid driven, single-freedom and flexible bending joint

A bending joint, fluid-driven technology, applied in artificial arms, artificial legs, manipulators, etc., can solve problems such as the inability to obtain a more accurate mathematical model for the bending deformation of the rubber wall, the poor dynamic control effect, and the insensitive movement, etc., to achieve dynamic control. High precision, small duty cycle, and low power/mass ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

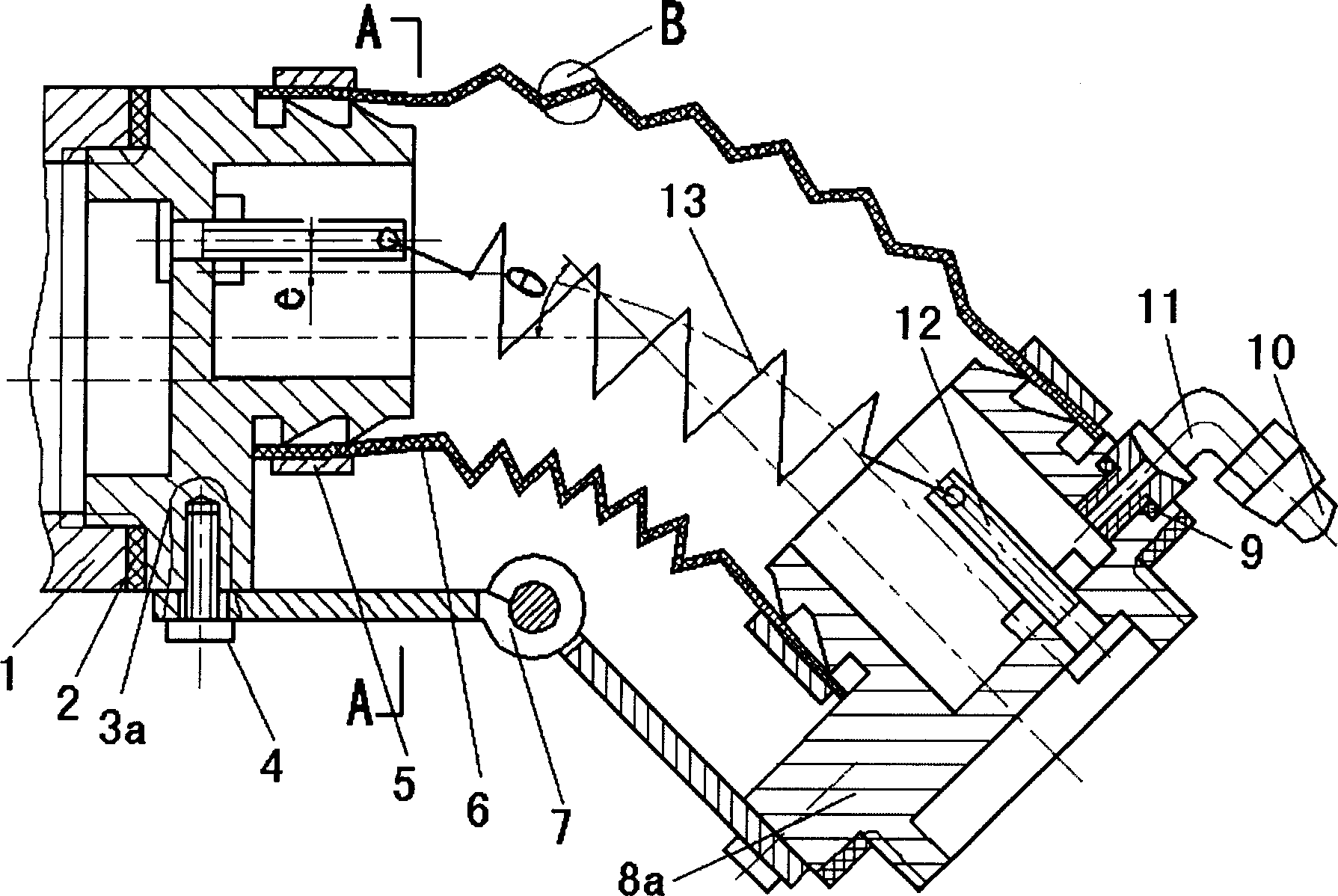

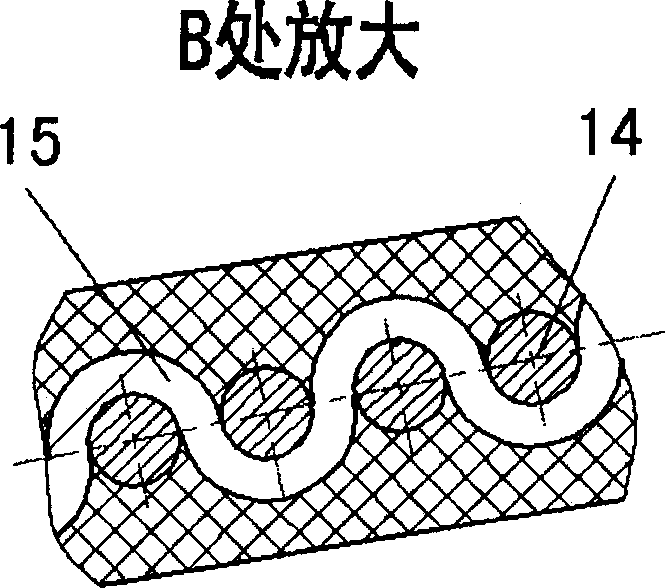

[0021] The present invention mainly consists of a finger cot 1, an adjusting gasket 2, a head seat 3a, a non-porous head seat 3b, a screw 4, a hoop 5, an elastic wave shell 6, a plate hinge 7, a tail stock 8a, a non-porous tail stock 8b, a seal Ring 9, hose 10, joint 11, hook shaft 12, tension spring 13, annular weft 14, warp 15, elastic strip 16, locking plate 17, torsion spring 18 and the like.

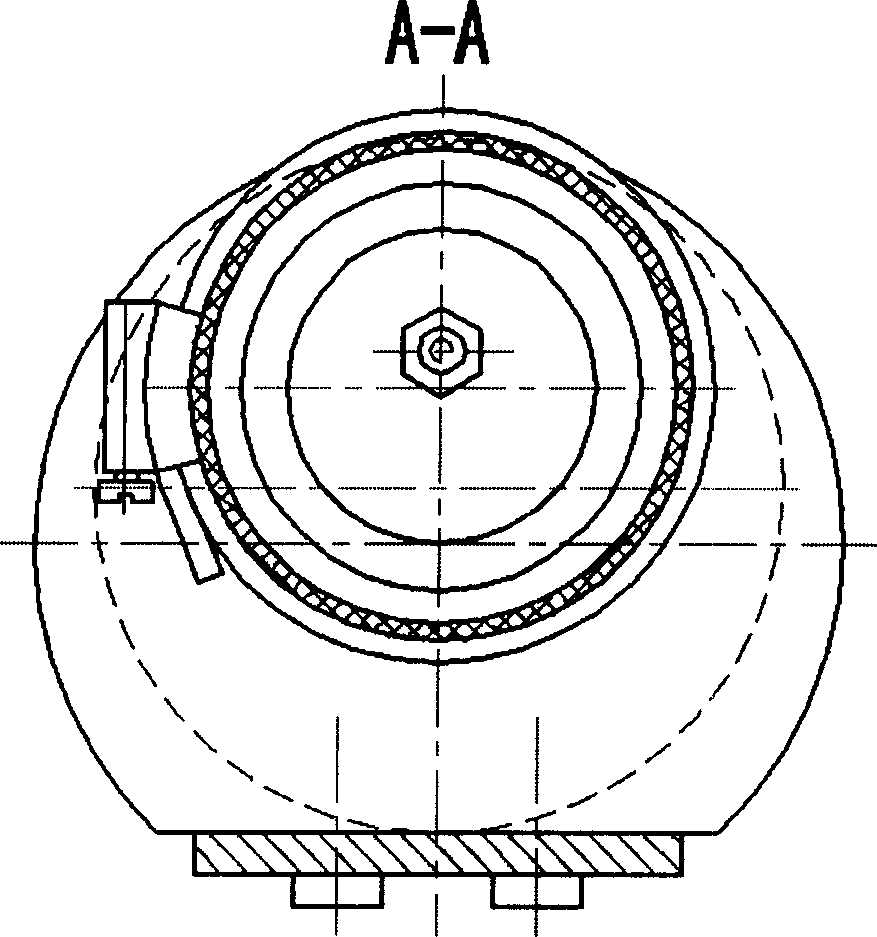

[0022] as attached figure 1 , 2 The first solution shown is: the elastic wave shell 6 is clamped on the bayonet of the headstock 3a and the tailstock 8a by the clamp 5, and the elastic wave shell 6, the headstock 3a and the tailstock 8a form a closed cavity; The fluid enters the joint cavity through the hose 10 and the joint 11, the joint 11 is screwed on the tailstock 8a, and there is a sealing ring 9 in the middle for sealing; the two ends of the plate h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com