Air lifting deep water type oxidizing tank

An oxidation ditch and air-lift technology, applied in the field of water treatment, can solve the problems of poor water quality treatment, low efficiency of nitrogen and phosphorus removal, etc., and achieve the effect of low infrastructure cost, simple equipment, and improved degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

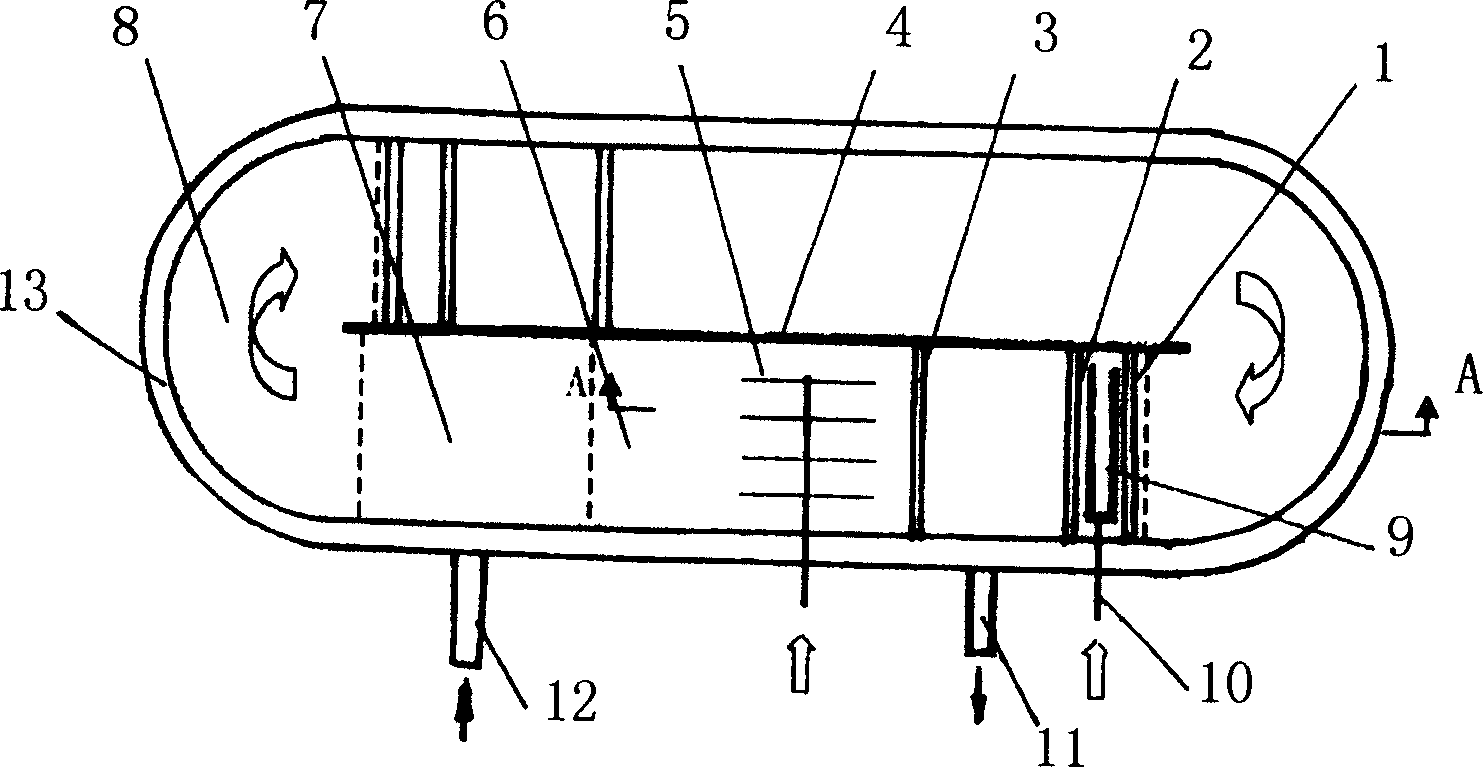

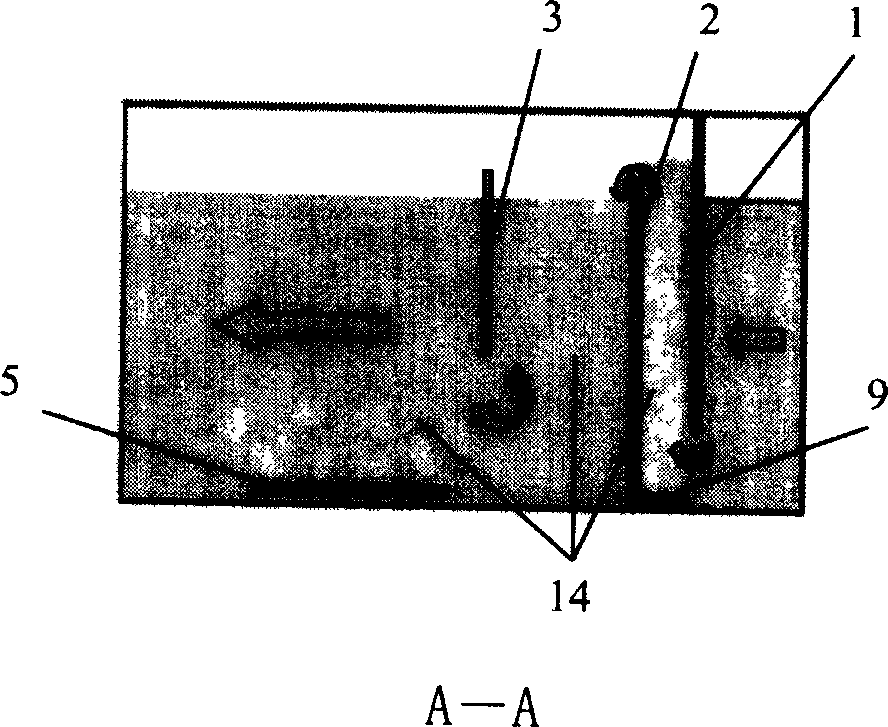

[0009] The invention provides an air-lift deep-water oxidation ditch. exist figure 1 , figure 2 In the shown structure, the oxidation ditch surrounded by the outer ditch wall 13 is divided into two parts symmetrical to the partition wall by the partition wall 4 and the baffles 1, 2 and 3, and the first aeration zone 9 is set in each part And the second aeration zone 5, in the aeration zone, be divided into a labyrinth channel 14 by baffles 1, 2 and 3, in each aeration zone, install the inlet pipe 10 as the aeration device respectively, one side of the oxidation ditch The wall is provided with a water inlet 12 and a water outlet 11. The sewage enters the oxidation ditch from the water inlet 12, and the air in the aeration zone enters from the bottom of the ditch and rises from the bottom of the ditch to the water surface; multiple aeration sections are placed at intervals in the oxidation ditch. Each aeration section is divided into two aeration areas; in the air-lift deep-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com