Concrete water-reducing agent and its production method

A concrete water-reducing agent and raw material technology, applied in the fields of concrete water-reducing agent and chemical admixture, can solve the problems of inability to meet the performance requirements of high-efficiency water-reducing agent, fast slump loss, low post-strength, etc. The effect of reducing the peak of cement hydration heat and reducing the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of concrete water reducer, its raw material composition and the raw material ratio with weight as the unit of measurement are:

[0024] Industrial naphthalene: washing oil = 1: 0.20;

[0025] (Industrial naphthalene + washing oil): sulfuric acid: formaldehyde: modifier: liquid caustic soda

[0026] =1:1:0.56:0.01:0.94.

Embodiment 2

[0028] Industrial naphthalene: wash oil = 1:0.40;

[0029] (Industrial naphthalene + washing oil): sulfuric acid: formaldehyde: modifier: liquid caustic soda

[0030] =1:1~11:0.7:0.02:1

Embodiment 3

[0032] Industrial naphthalene: washing oil = 1: 0.55;

[0033] (Industrial naphthalene + washing oil): sulfuric acid: formaldehyde: modifier: liquid caustic soda =

[0034] =1:1.1:0.93:3:1.70.

[0035] The production method of water reducing agent of the present invention is:

[0036] a. Melting: Add washing oil and industrial naphthalene in the reaction tank according to the ratio, heat it up to 120~130°C to melt;

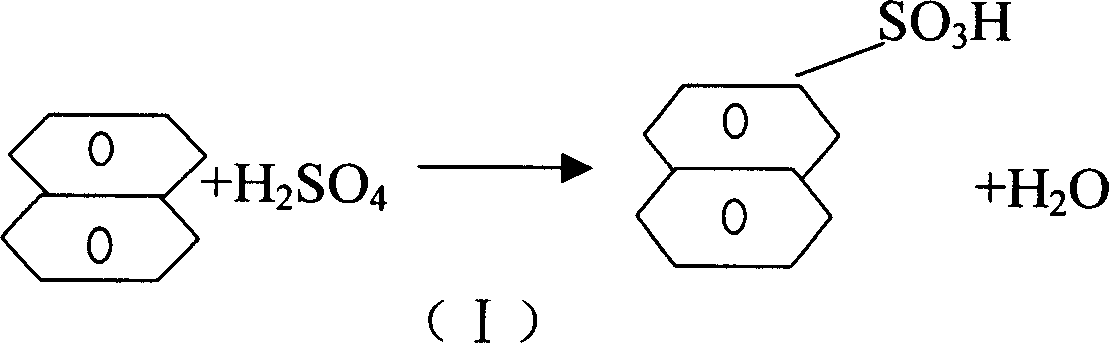

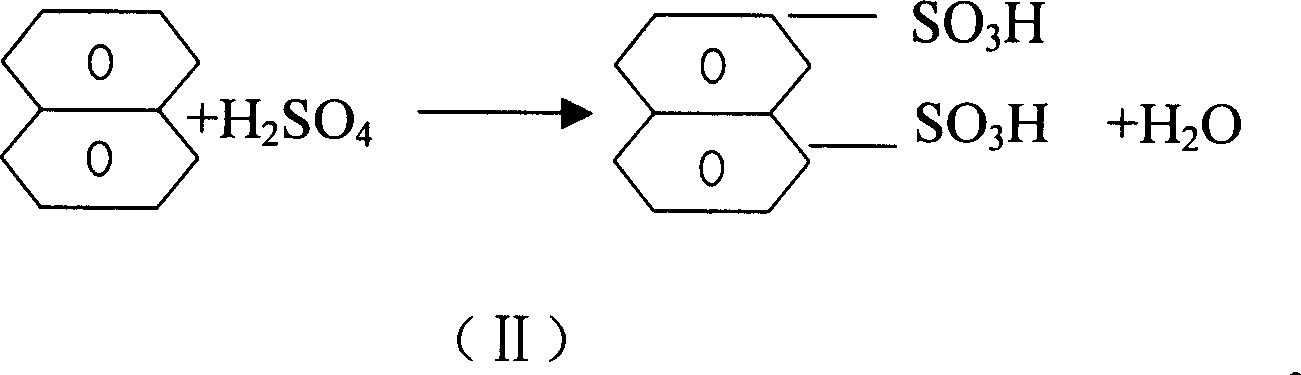

[0037] b. Sulfonation: add concentrated sulfuric acid to make it sulfonate, control the temperature at 150~160℃, keep it warm for 2~4 hours, and generate aromatic ring sulfonic acid derivatives;

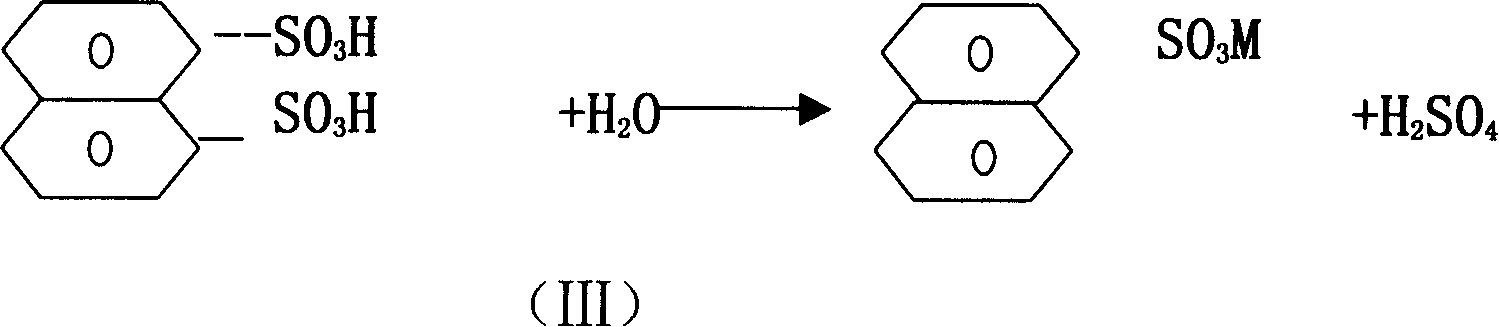

[0038] c. Hydrolysis: at 80°C, add cold water for hydrolysis to remove 2-aromatic ring sulfonic acid;

[0039] d. Modification: add a modifier to form a carboxyl group during condensation to carry out side-connected grafting modification to suppress the air-entraining of groups such as methyl groups, and simultaneously adjust the acidity to 30%.

[0040] The working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com