Intelligent system for measuring yield based on remote data transmission

A remote data transmission and intelligent technology, applied in the field of measurement systems, can solve the problems of large grain density changes, radioactive contamination, and less use, and achieve the effects of extending the use space, improving practicability, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

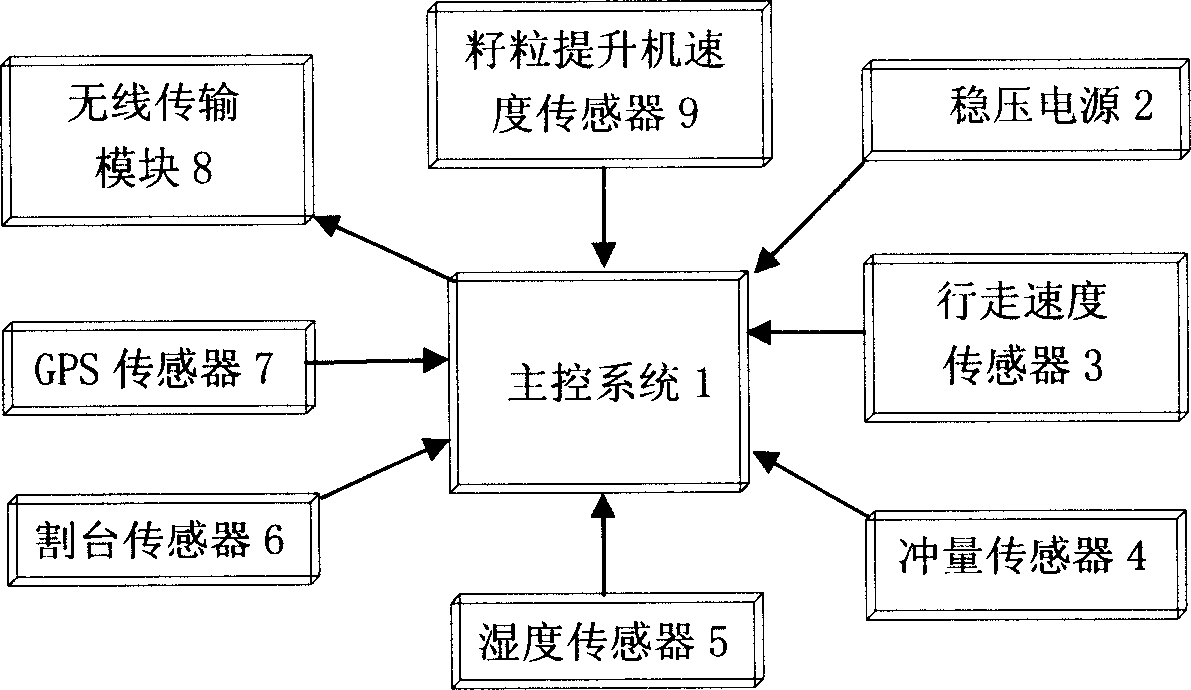

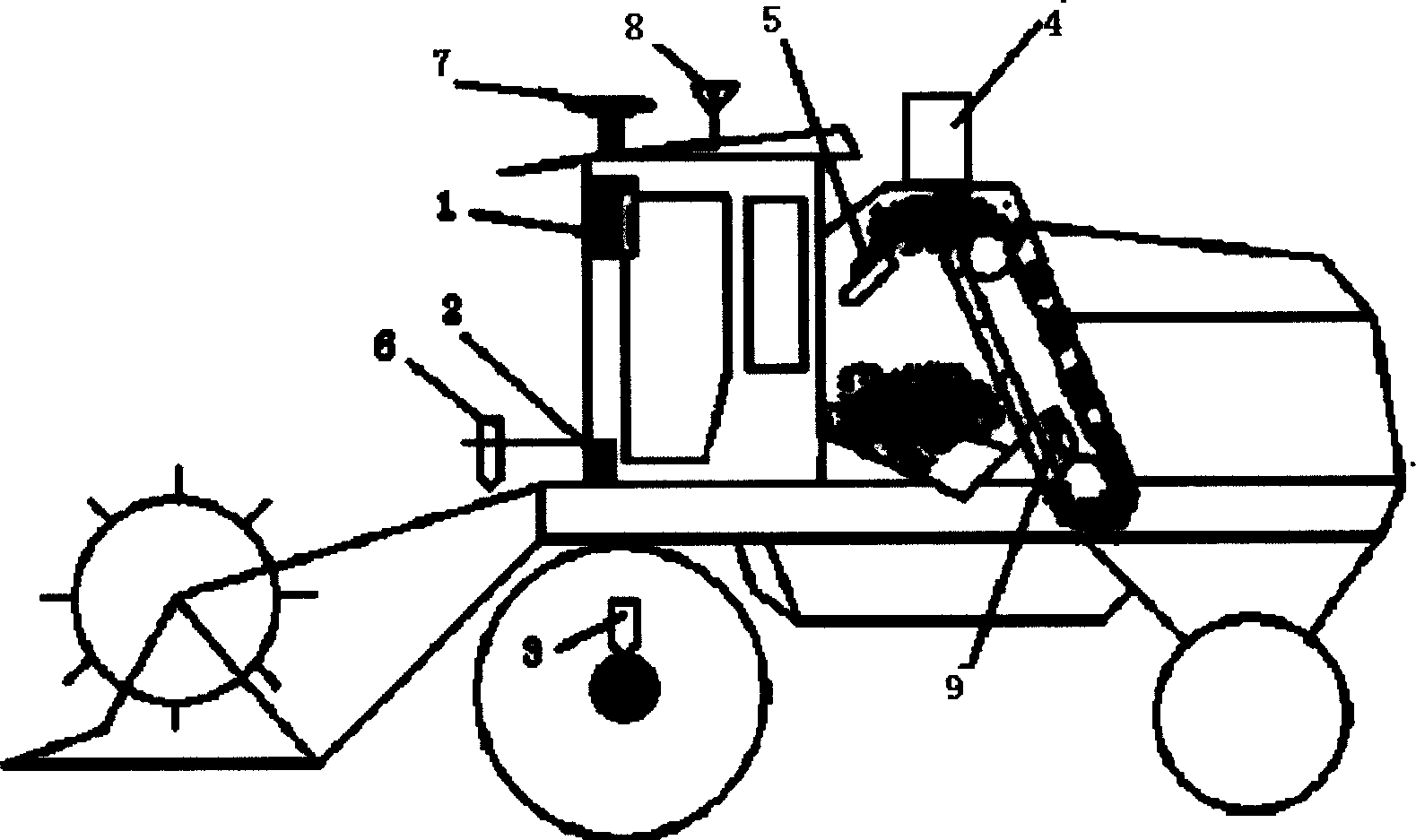

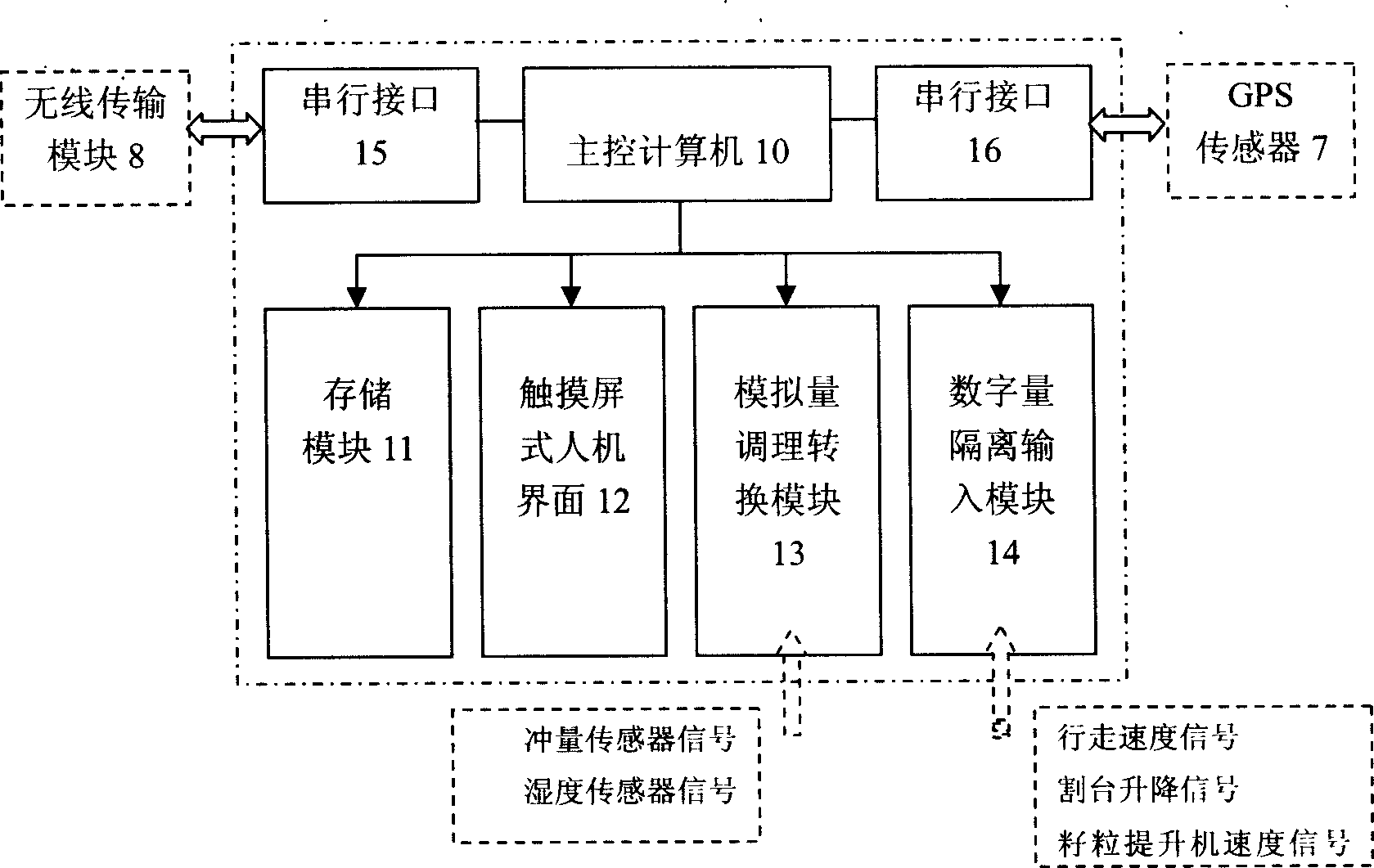

[0014] Such as figure 1 , 2 As shown, the present invention includes: a main control system 1, a stabilized power supply 2, a walking speed sensor 3, an impulse sensor 4, a humidity sensor 5, a header sensor 6, a GPS sensor 7, a wireless transmission module 8 and a grain hoist speed sensor 9 . The connection method is as follows: the main control system 1 and the stabilized power supply 2 are set in the cab of the harvester and connected by wires, and the walking speed sensor 3 is set above the front drive wheel shaft of the harvester to measure the number of wheel rotations and transmit it to the main control system 1 , after being processed by the main control system 1, the walking speed of the harvester is obtained. The impulse sensor 4 is set at the exit of the grain hoist on the top of the grain cabin to measure the impulse generated by the grain flow coming out of the grain hoist in real time. The humidity sensor 5 is set inside the grain cabin Facing the exit of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com