System for monitoring resistance of electric fuse

An electric fuse and resistance technology, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve identification difficulties, programming process and debugging difficulties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

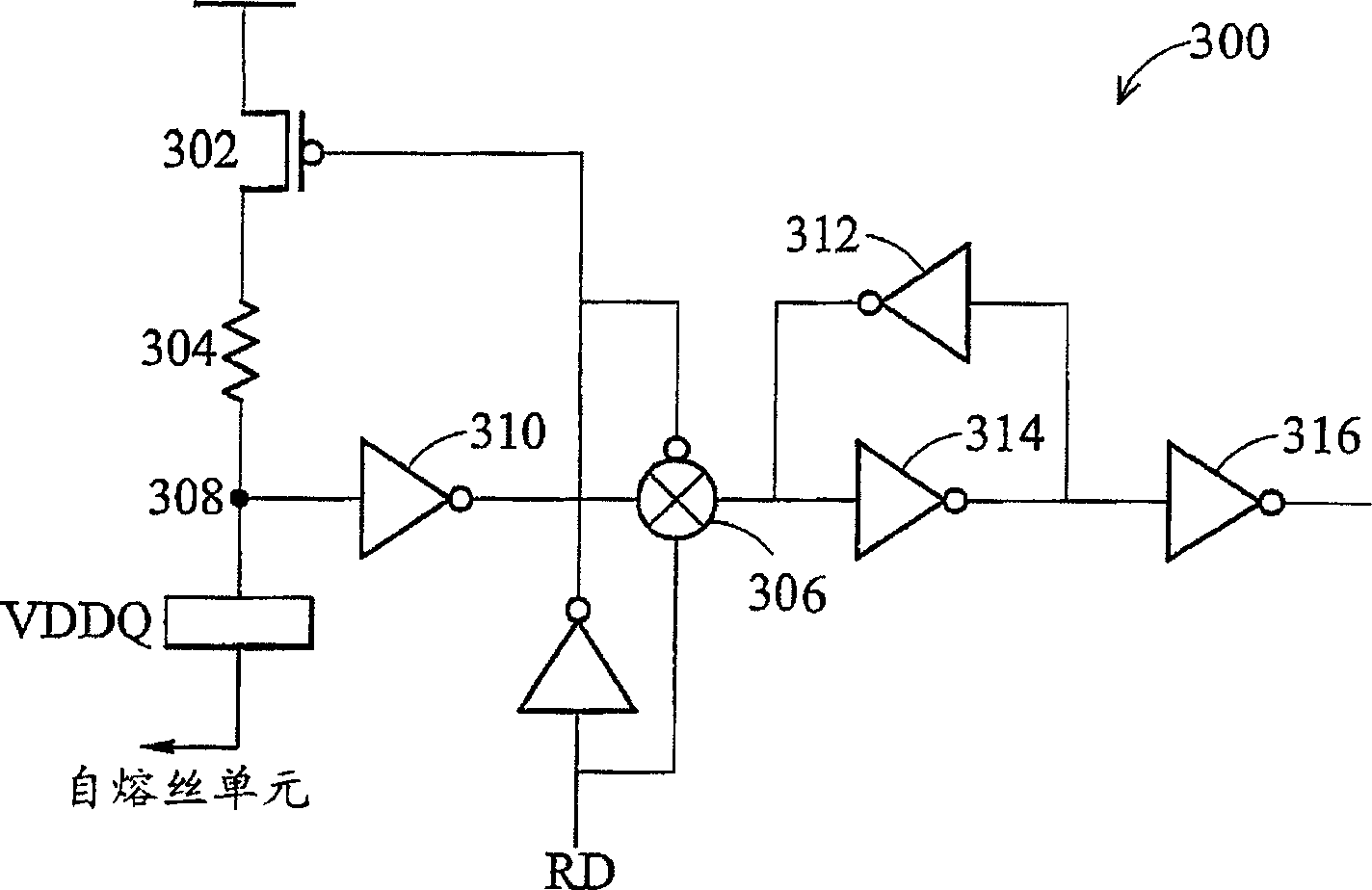

[0038] The operation of the method and device of the present invention will be described in detail with specific examples and figures in the following implementation modes, so that readers can understand the convenience obtained by using the present invention.

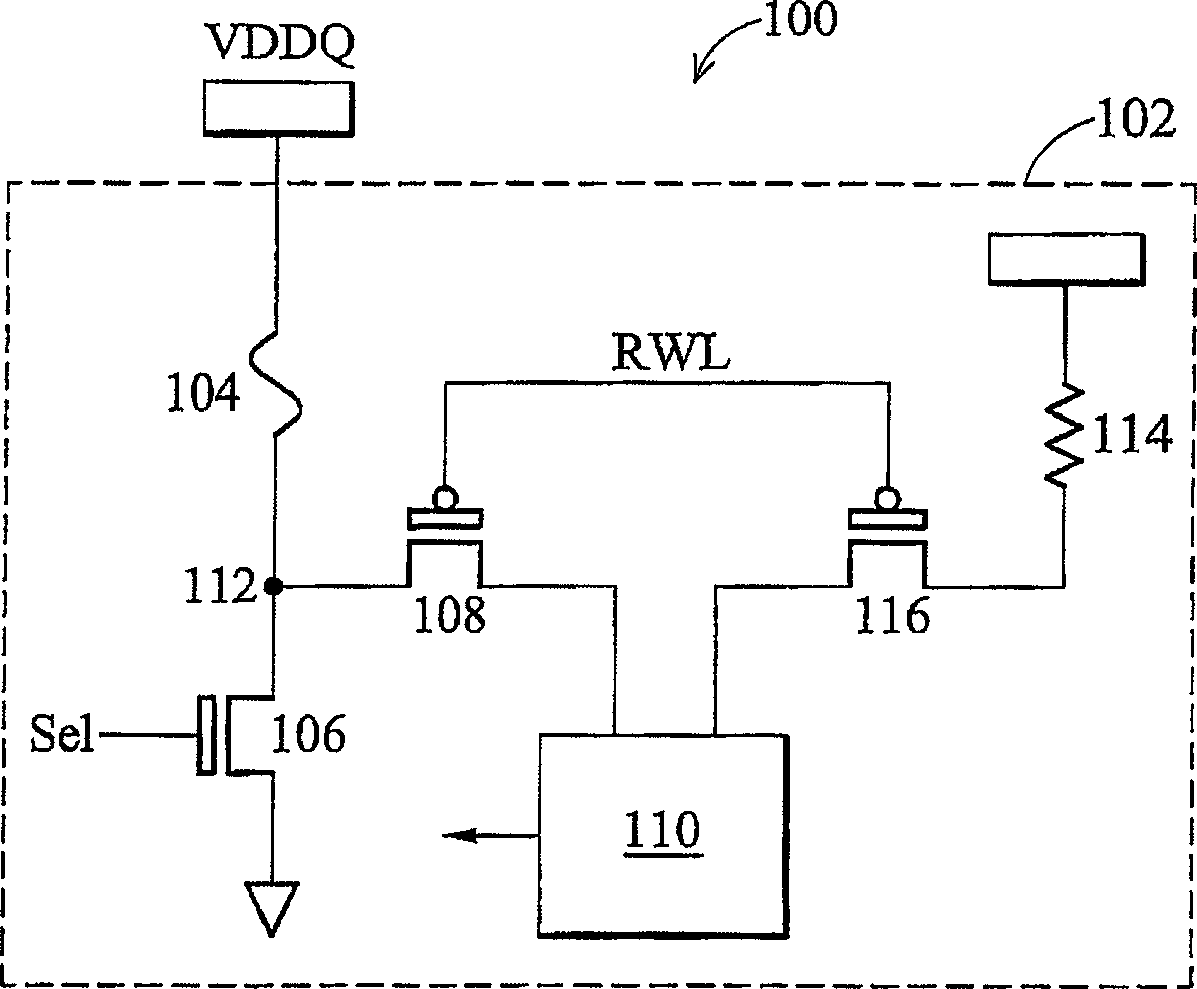

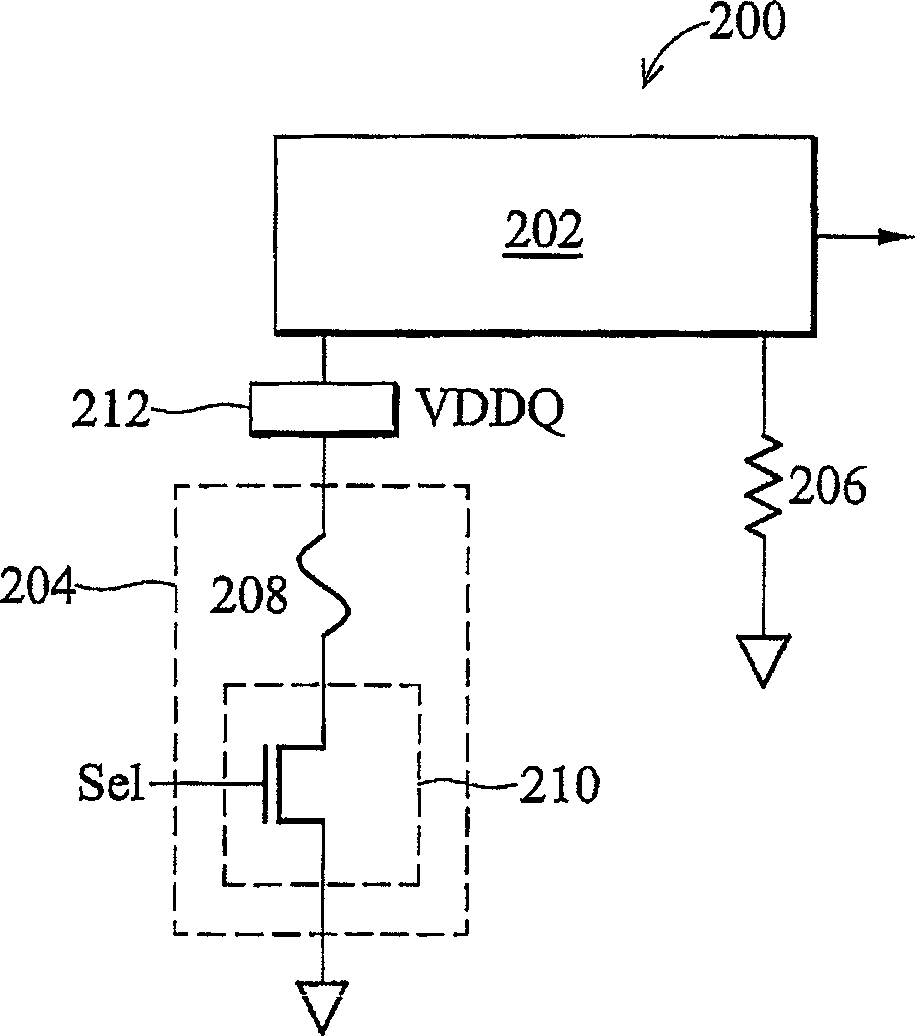

[0039] In the prior art, a fuse macro is formed by a plurality of fuse elements, and the fuse macro is called a fuse unit here. In order to monitor the fuse resistance value, a test circuit is built in the fuse macro so that an external tester can program and analyze the fuse unit. Unfortunately, it is difficult to distinguish the relationship between the external test circuit and a fuse element in the fuse macro, and the test circuit often occupies a large substrate area. The present invention provides a new type of circuit (on-chip fuse resistance monitoring and diagnosis circuit) that monitors the resistance of the fuse on the chip without additional testing circuit, so as to solve the problems in the prior art.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com