Automated testing system and method for light emitting diode

A light-emitting diode and automated testing technology, which is applied in photometry, optical performance testing, optical radiation measurement, etc., can solve the problems that the accuracy and function cannot meet people's needs, and achieve increased testing, accurate classification, and high testing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

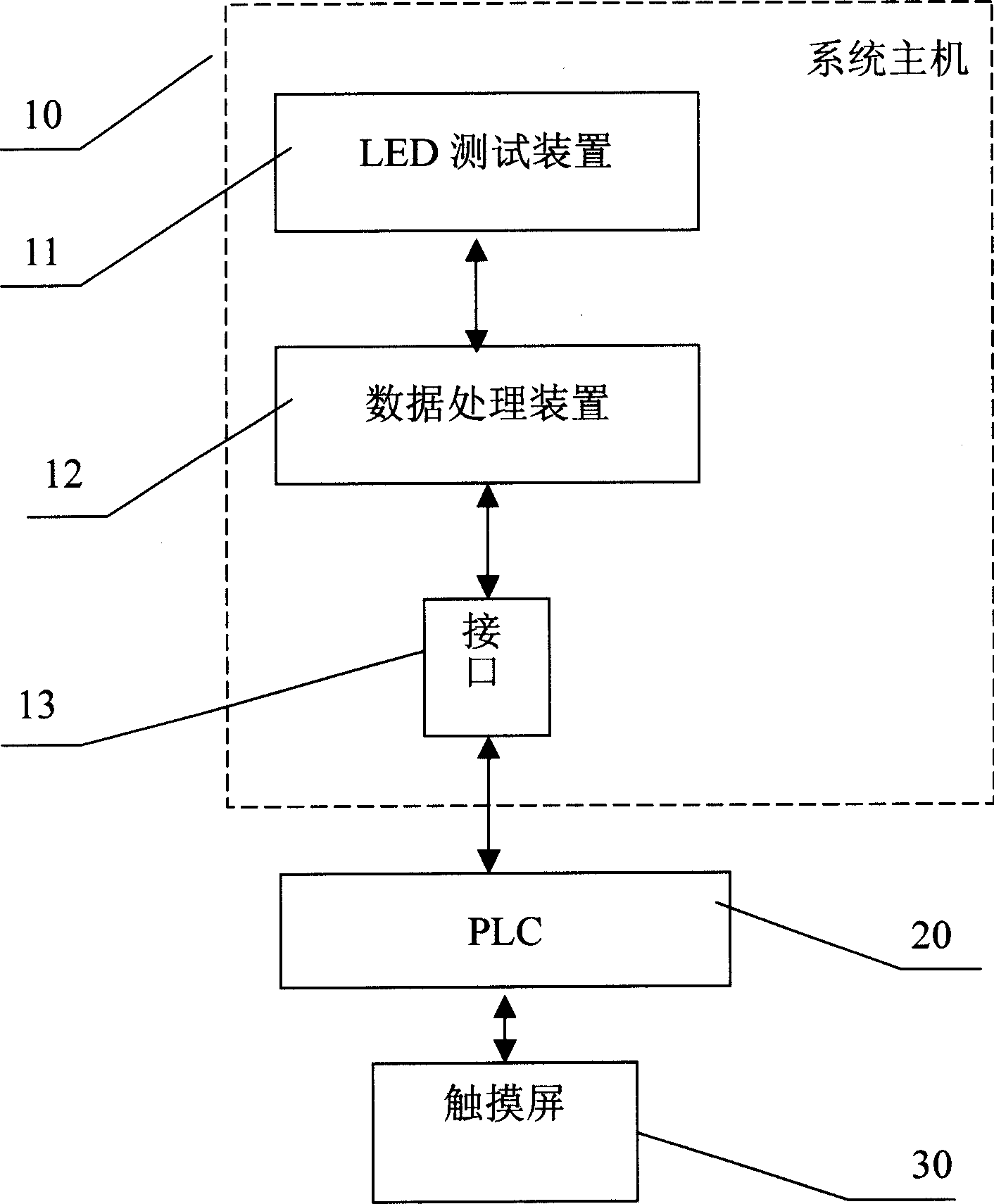

[0034] See figure 1 , a kind of automatic testing system of light-emitting diode, comprise system host 10, touch screen 30, PLC20, system host 10 comprises the LED testing device 11 of testing light-emitting diode electrical and optical parameter, the data processing of the data of tested light-emitting diode is processed The device 12 , and the interface 13 for realizing mutual communication between the data processing device 12 and the PLC20 ; and the touch screen 30 connected with the PLC20 .

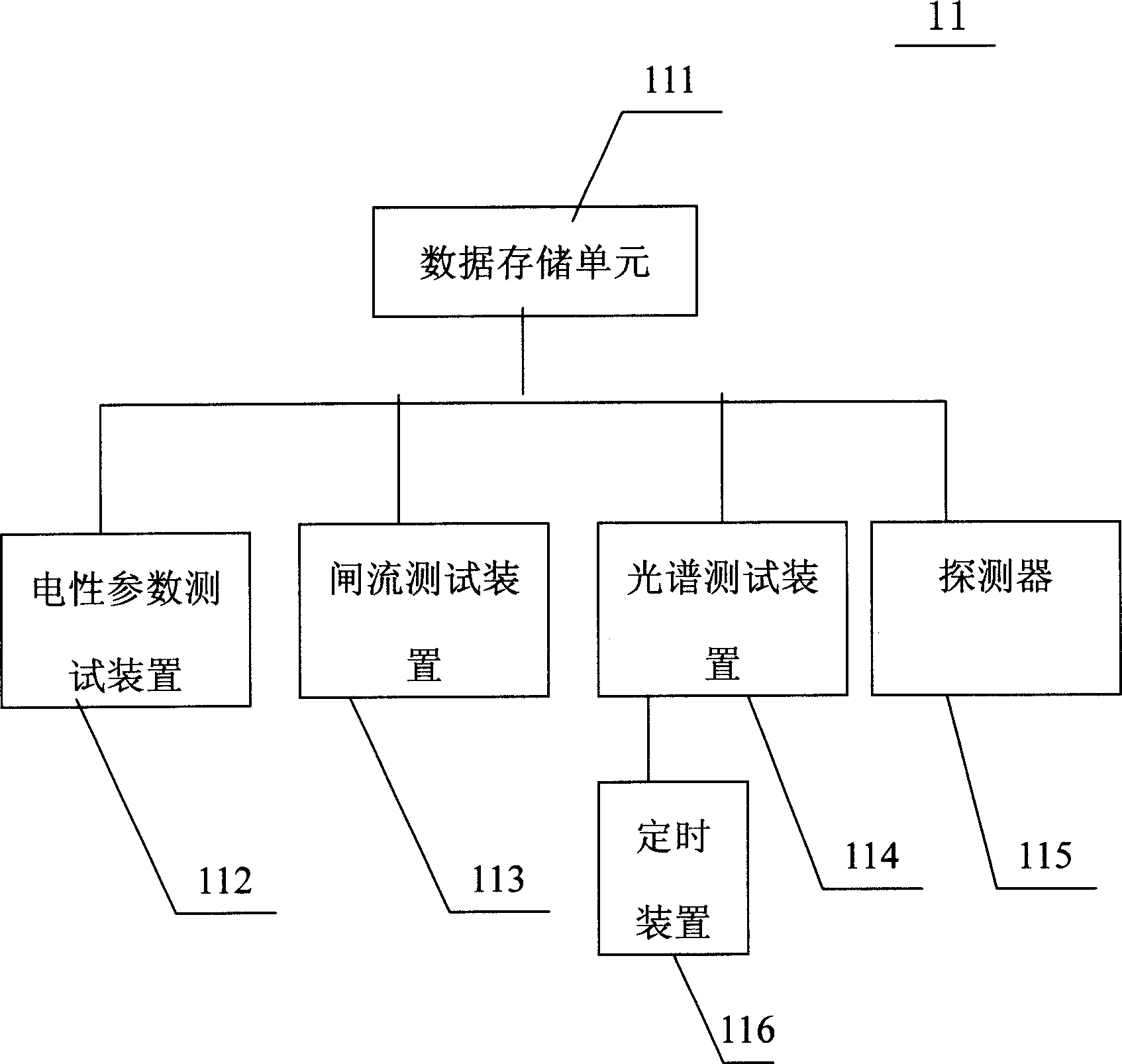

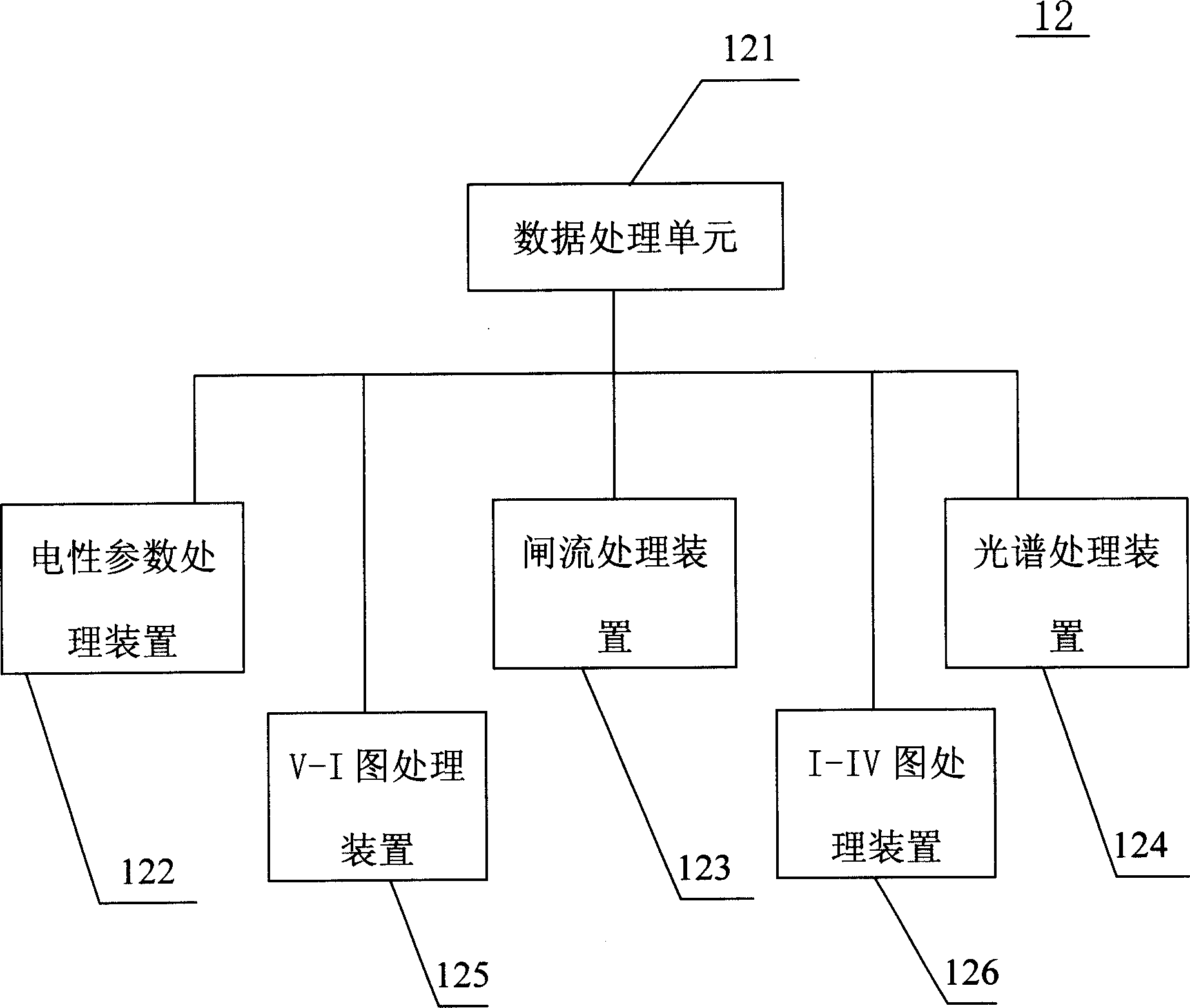

[0035] See figure 2 , the LED testing device 11 includes a data storage unit 111, an electrical parameter testing device 112 for testing the current and voltage of the LED, a thyristor testing device 113 for testing the thyristor of the LED, a spectrum testing device 114 for testing the optical parameters of the LED, and A detector 115 for testing the light intensity of the LED. See image 3 The data processing device 12 includes an electrical parameter processing device 122 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com