Vortex compressor

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve the problems of weak assembly force, high sleeve price, time-consuming processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, several embodiments of the present invention will be described with reference to the drawings. The same symbols in the drawings of the respective embodiments represent the same or corresponding components.

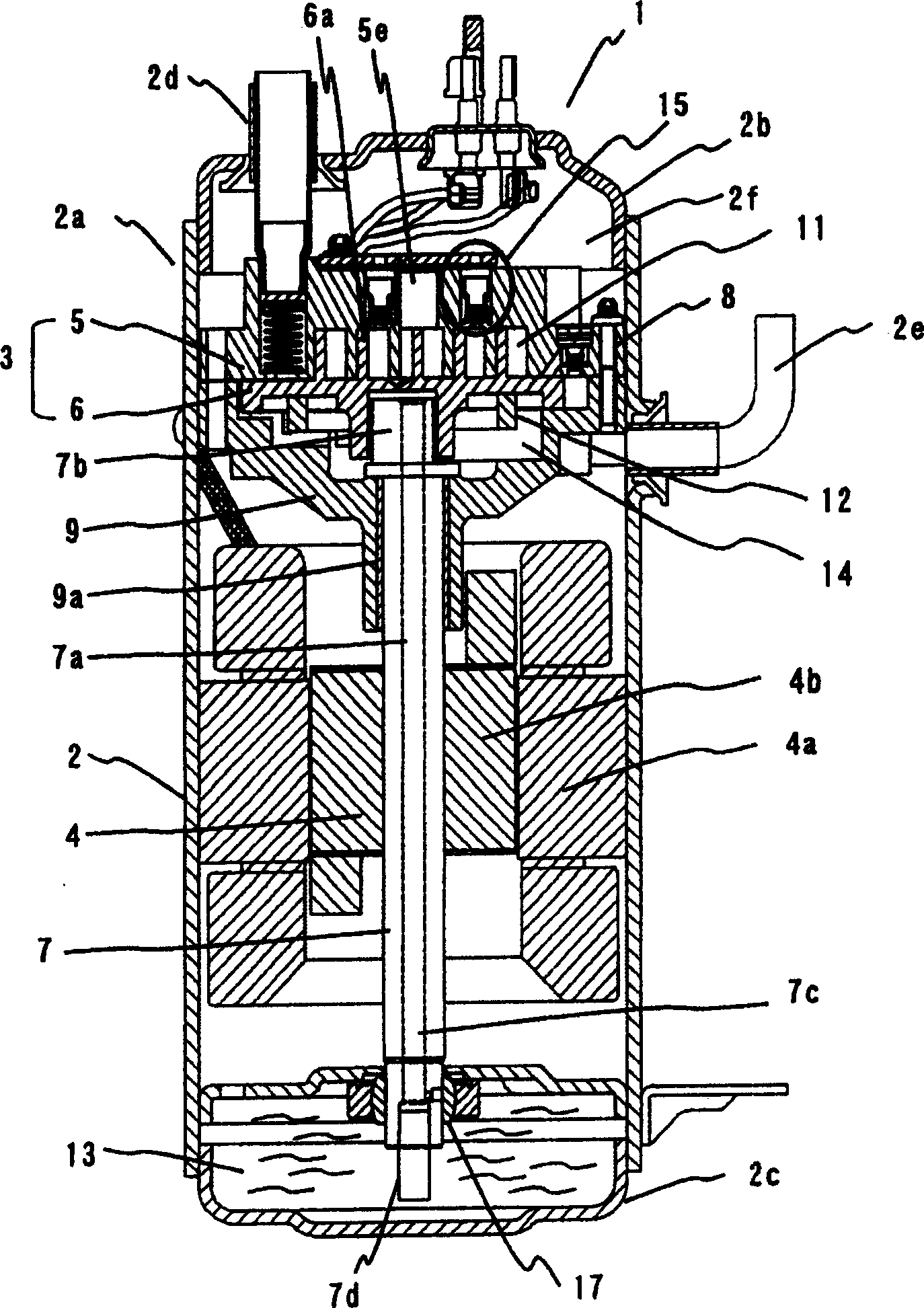

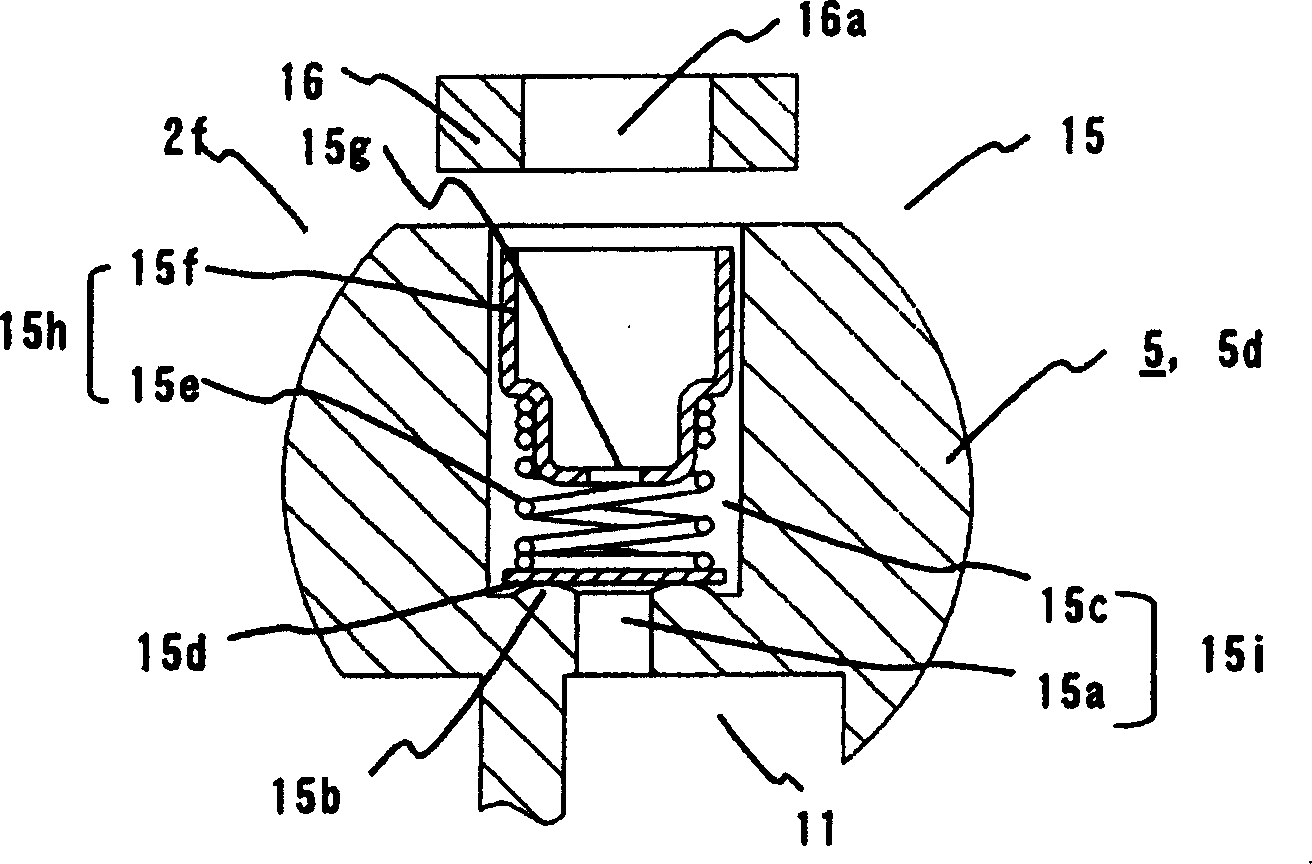

[0044] Initially, with Figure 1 to Figure 6 A scroll compressor according to a first embodiment of the present invention will be described.

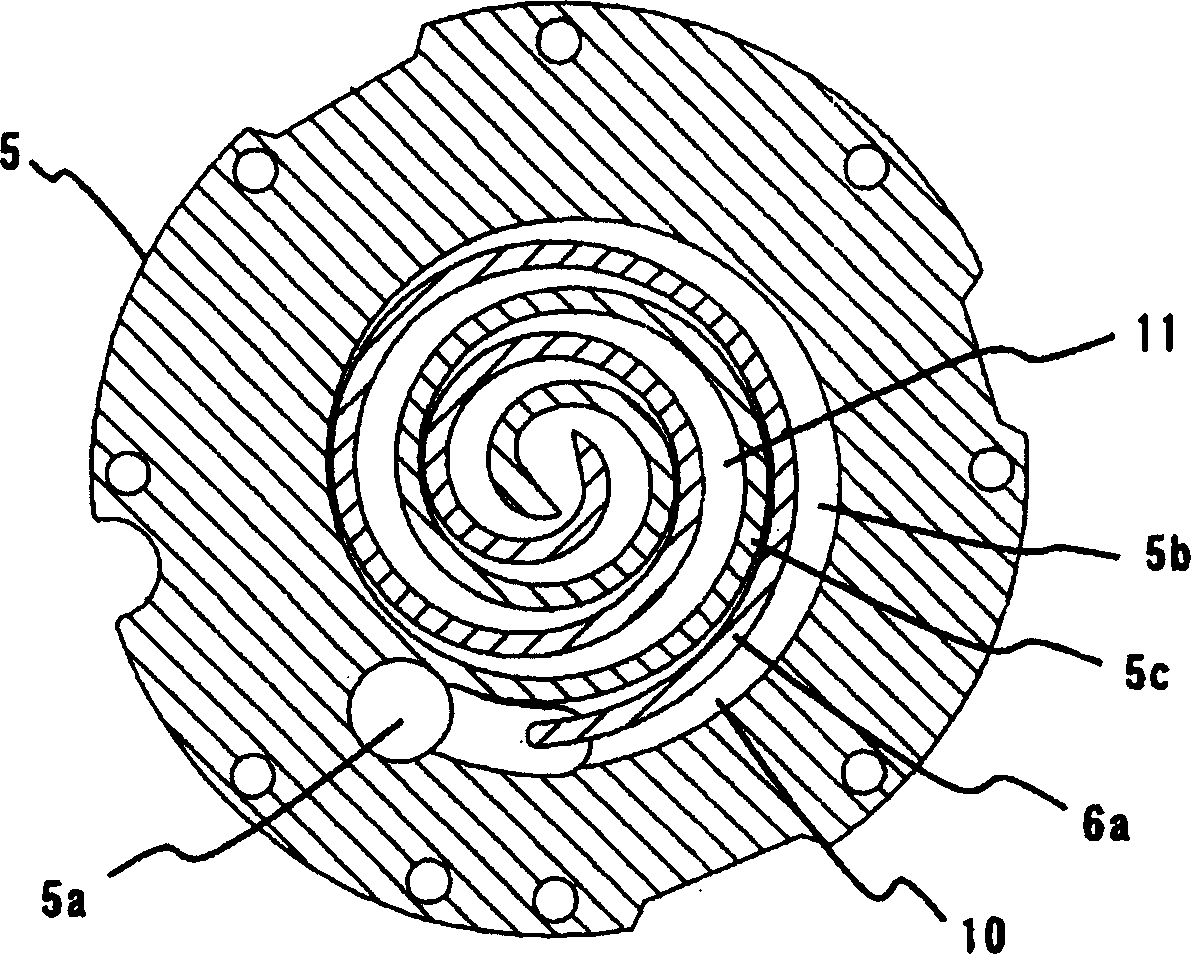

[0045] First, refer to figure 1 as well as figure 2 The overall structure of the scroll compressor 1 of this embodiment will be described, figure 1 is a longitudinal sectional view of a scroll compressor according to a first embodiment of the present invention, figure 2 yes figure 1 A cross-sectional view of the compression mechanism.

[0046] The scroll compressor 1 is composed of a high-pressure chamber type hermetic scroll compressor, and is used under a wide range of operating conditions as part of a refrigeration cycle such as a room air conditioner. The scroll compressor 1 is provided with: a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com