Solid electrolytic capacitor and method for manufacturing the same

A technology of solid electrolysis and manufacturing methods, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitor manufacturing, etc., can solve the problems of capacitor capacitance reduction, TCNQ compound salt electrolyte impregnation efficiency, etc., to achieve good impedance characteristics and reduce the possibility of deterioration , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

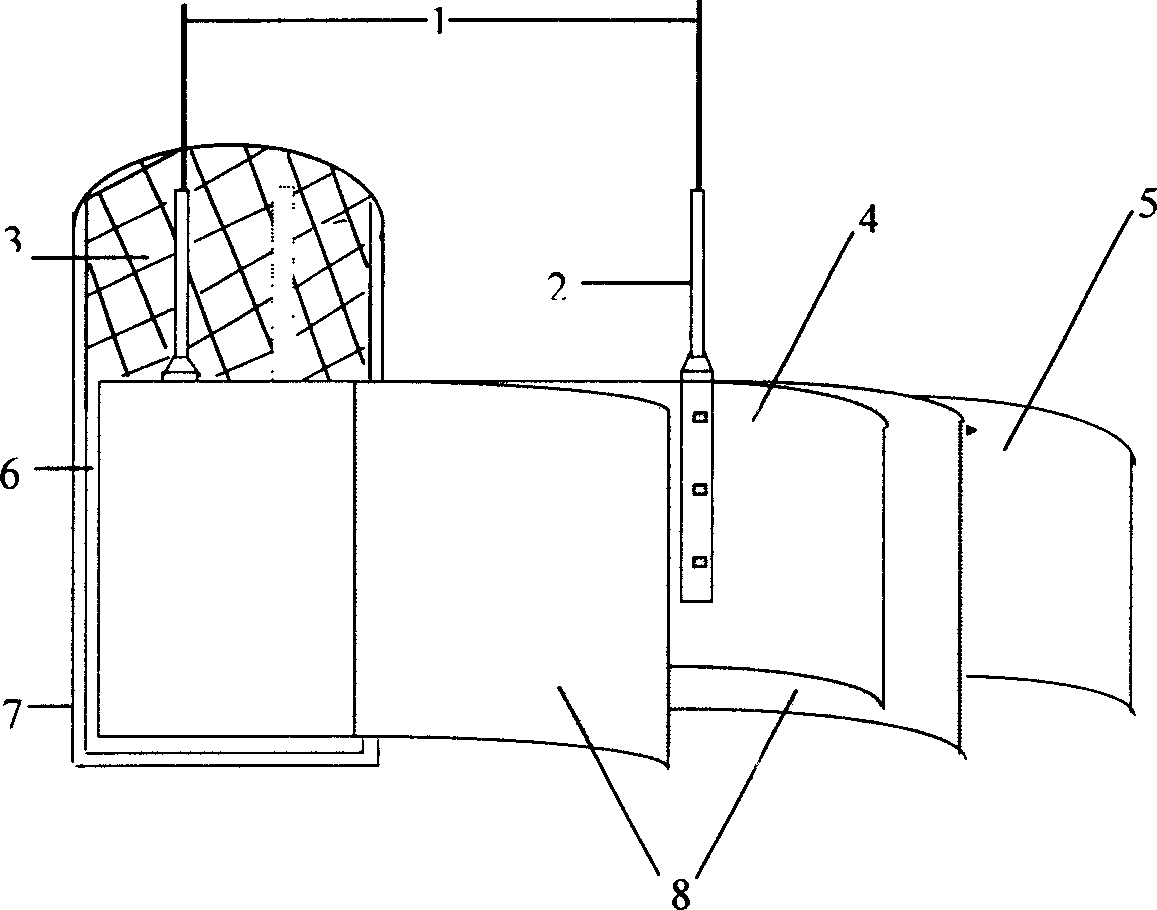

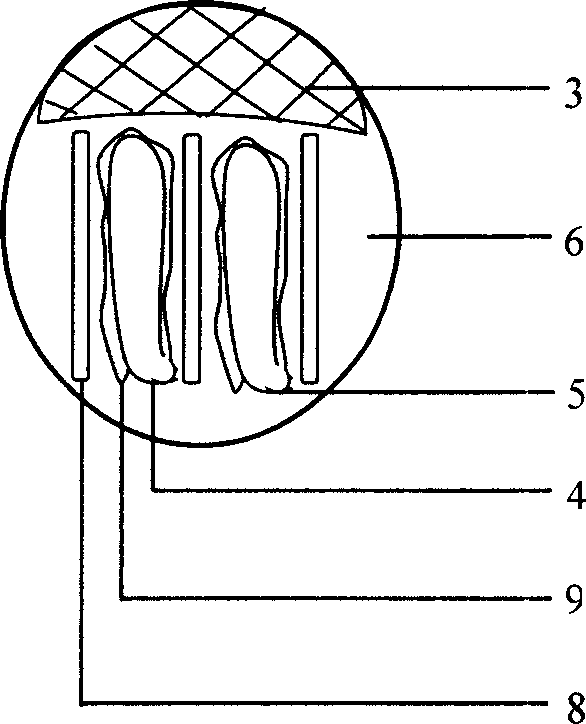

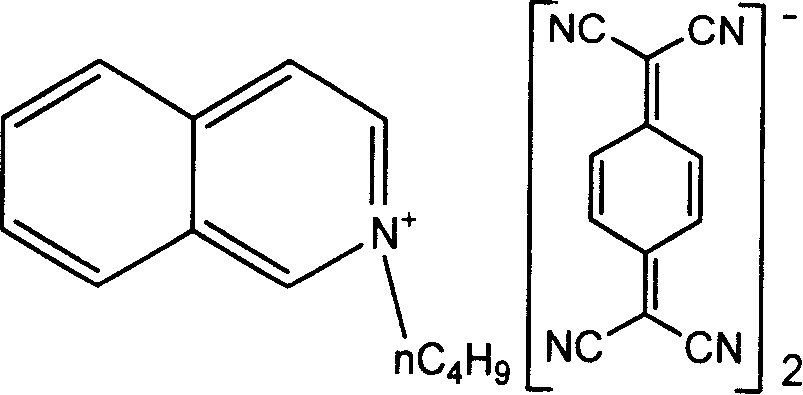

[0047] Insert electrolytic paper containing Manila hemp fiber (density 0.2-0.6g / cm2) between the anode foil and the cathode foil 3 , with a thickness of 30-60 μm), and roll them up to form wound capacitor cores, impregnate them with liquid electrolyte, age the cores at room temperature for 3 hours, and then place them at 240°C for 120 minutes to completely carbonize the electrolytic paper. Then, immerse the preheated capacitor core in the double salt of TCNQ n-butylisoquinoline in the molten state, after 30 seconds of immersion time, quickly cool down, and directly form a TCNQ double salt layer between the electrodes, and its rated voltage is 4V, The capacitance is 560μF. The capacitor element is put into an aluminum metal shell, and then the opening is sealed with epoxy resin or butyl rubber, and finally aged and sorted, so that an aluminum electrolytic capacitor with a size of D8mm×L10.5mm can be produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com