A reciprocating liquid pump for delivery of liquid fuel to a domestic burner device

A technology of reciprocating motion, liquid fuel, applied in parts of pumping device for elastic fluid, liquid fuel engine, liquid fuel supply/distribution, etc., can solve the problems of complex manufacturing cost of pump, not optimal, large pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

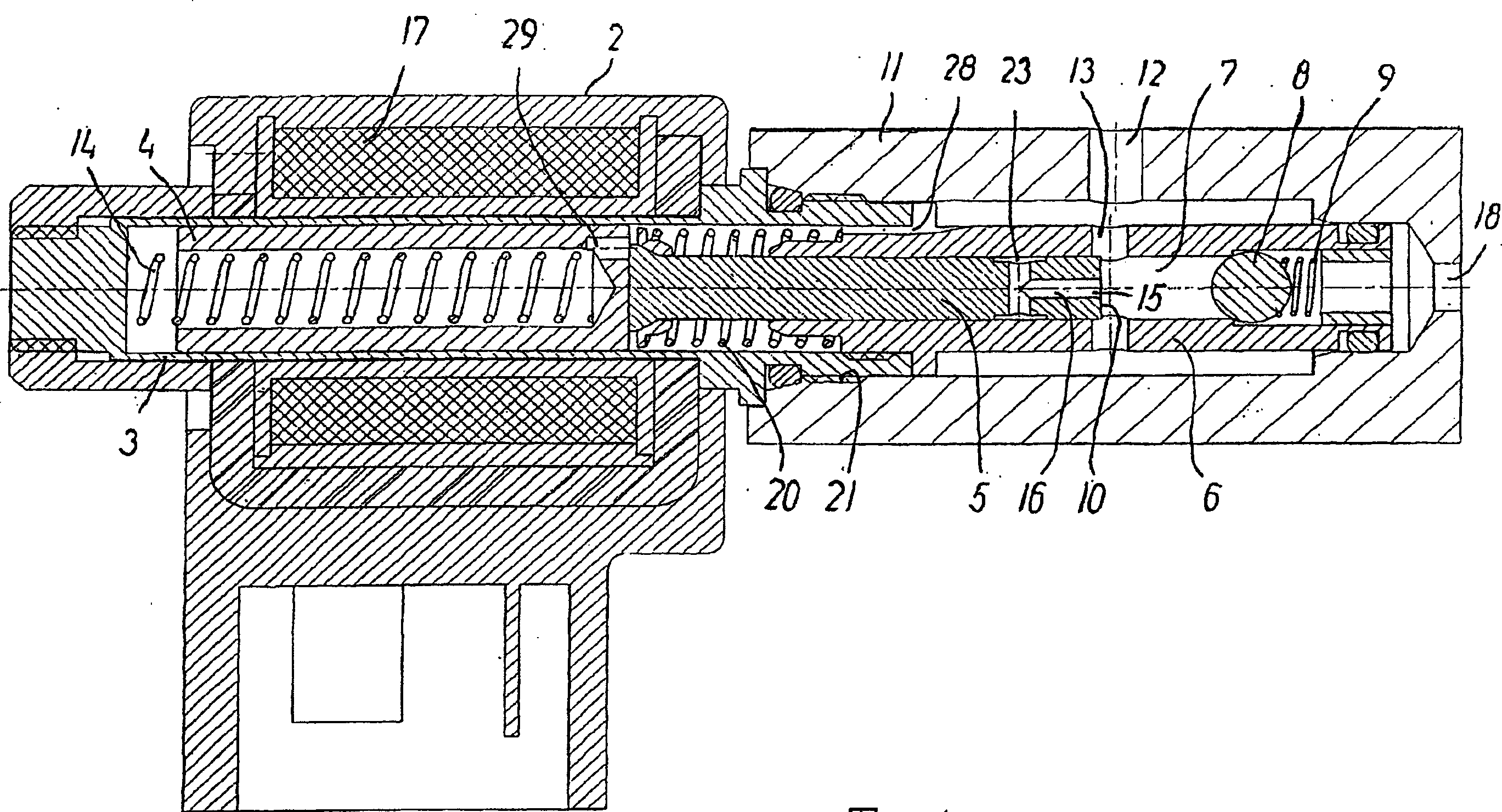

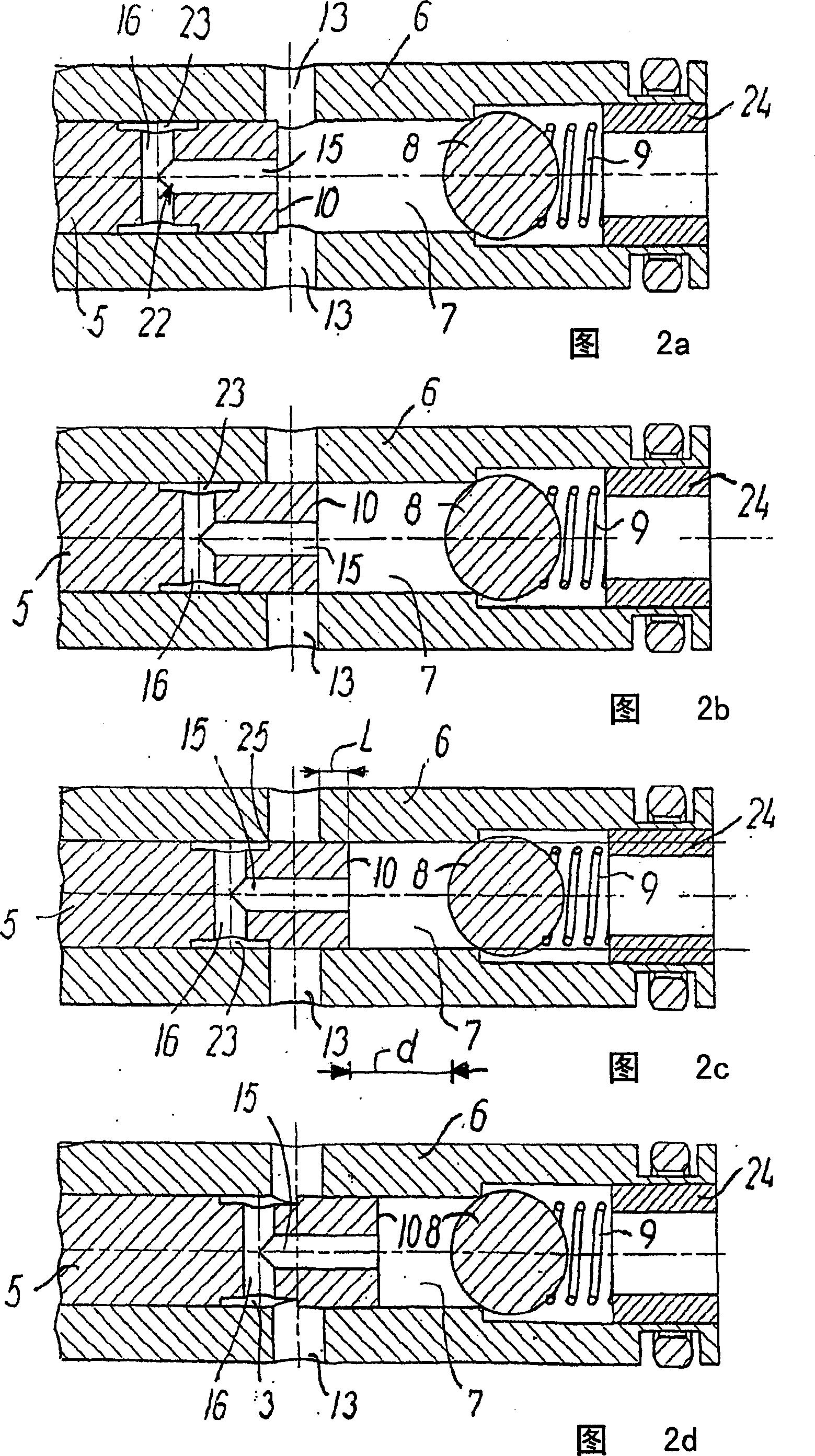

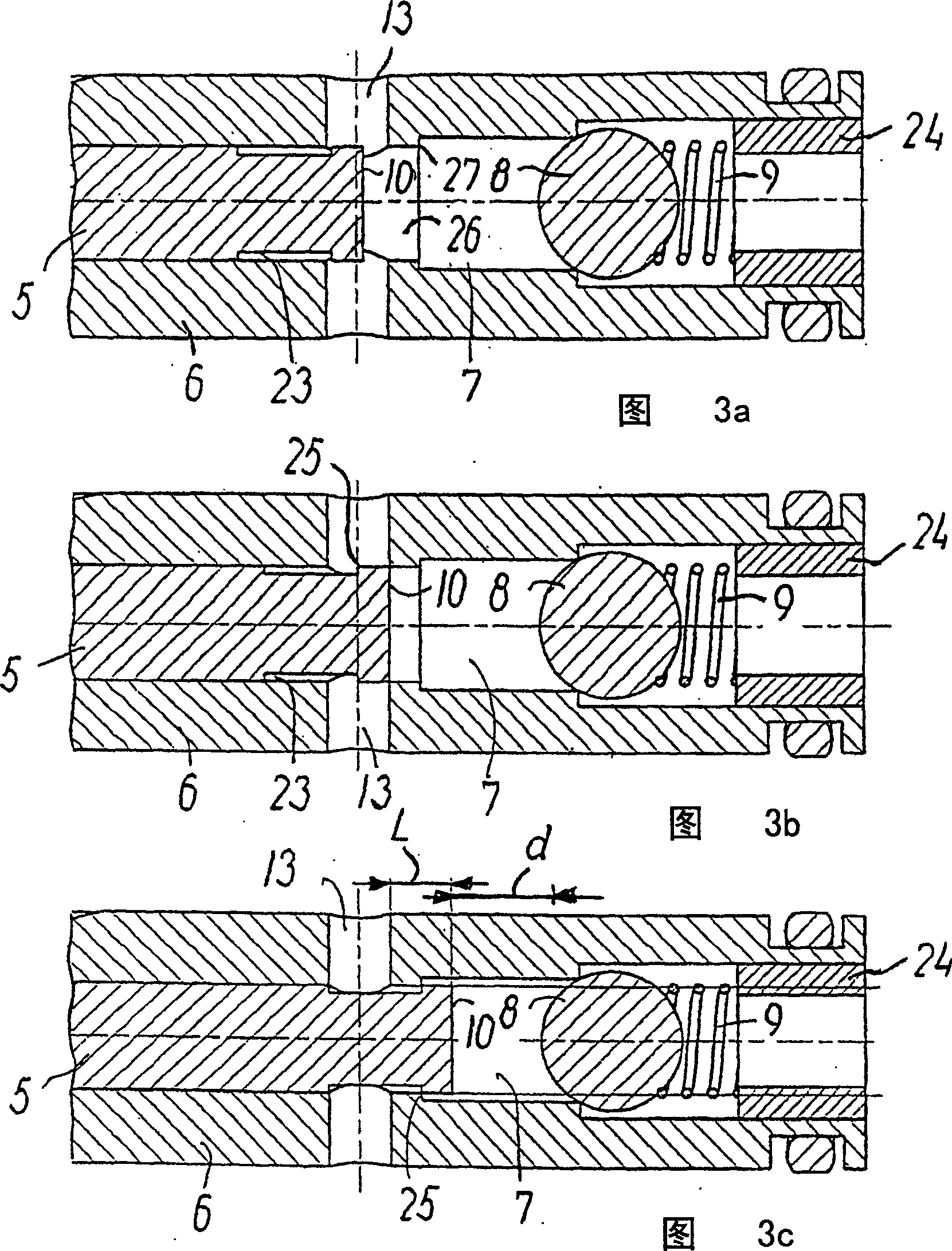

[0033] For purposes of illustration, the invention is embodied in the form of an atomizing unit for metering small quantities of fuel oil from a container (not shown) or priming pump (not shown) to a burner of an oil fired heating system or to a vehicle engine A liquid pump for metering fuel to the burner unit of the heater (not shown). In the description of the present invention, the term household should be understood in a broad sense to cover domestic burner installations in a domestic central heating system as well as in peripheral equipment belonging to the household, eg a vehicle or a boat.

[0034] The pump comprises a housing 2 for an electromagnet coil 17 which can be connected to a power source which provides a current cycle or pulse. The electromagnet is a standard part, eg Danfoss part serial number 71N0802. An armature cylinder 3 extends through the housing 2 and within the cylinder 3 an armature 4 is arranged to be reciprocated by an electromagnet. The armature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com