Choline chloride mixing and producing process

A technology of choline chloride and production process, applied in the field of mixing of choline chloride and production process, can solve problems such as high operating cost, high one-time investment, dangerous operating conditions, etc. The effect of improving the workshop environment and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

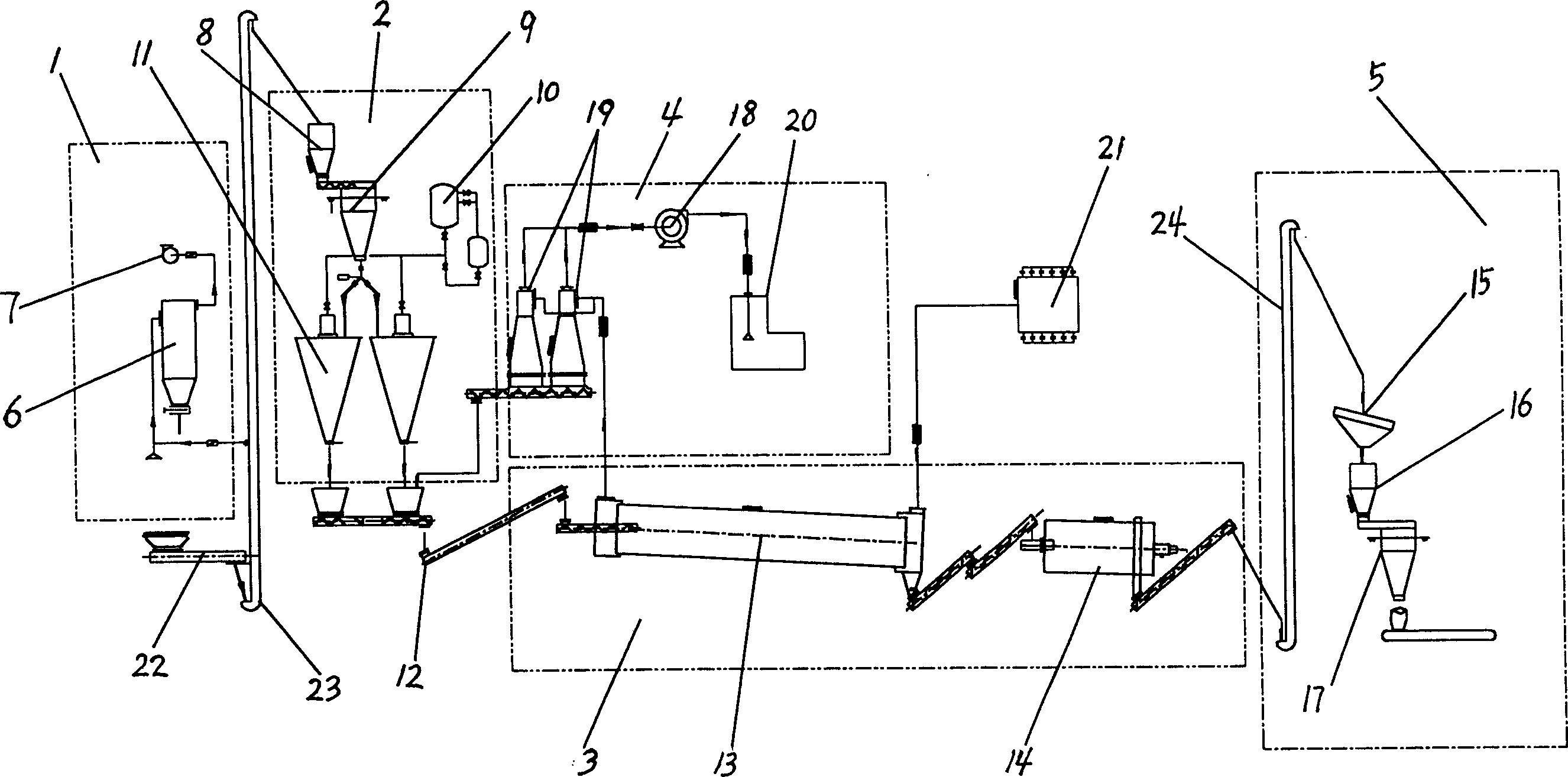

[0015] Accompanying drawing has provided process flow chart of the present invention. The process flow chart is the process flow chart of the mixing and drying system of 10,000 tons of choline chloride. It consists of five parts: material mixing, material drying, finished material weighing, dust removal and workshop purification. It consists of mixing system 2, The drying system 3, the finished material weighing system 5, the dust removal system 4 and the workshop purification system 1 are completed. Among them: workshop purification system 1 includes bag filter 6 and induced draft fan 7; mixing system 2 includes buffer bin 8, weighing bin 9, choline oil quantitative input equipment 10 and mixing bin 11; drying system 3 includes rotary cylinder drying Dryer 13, steam heat exchanger 21 and cooler 14; finished material weighing system 5 includes screening machine 15, buffer bin 16 and weighing bin 17; dust removal system 4 includes induced draft fan 18, cyclone dust collector 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com