Electrolytic capacitor

A technology of electrolytic capacitors and capacitors, which is applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., and can solve the problems of low impedance characteristics, low moisture resistance of electrolytic capacitors, and inability to meet high withstand voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

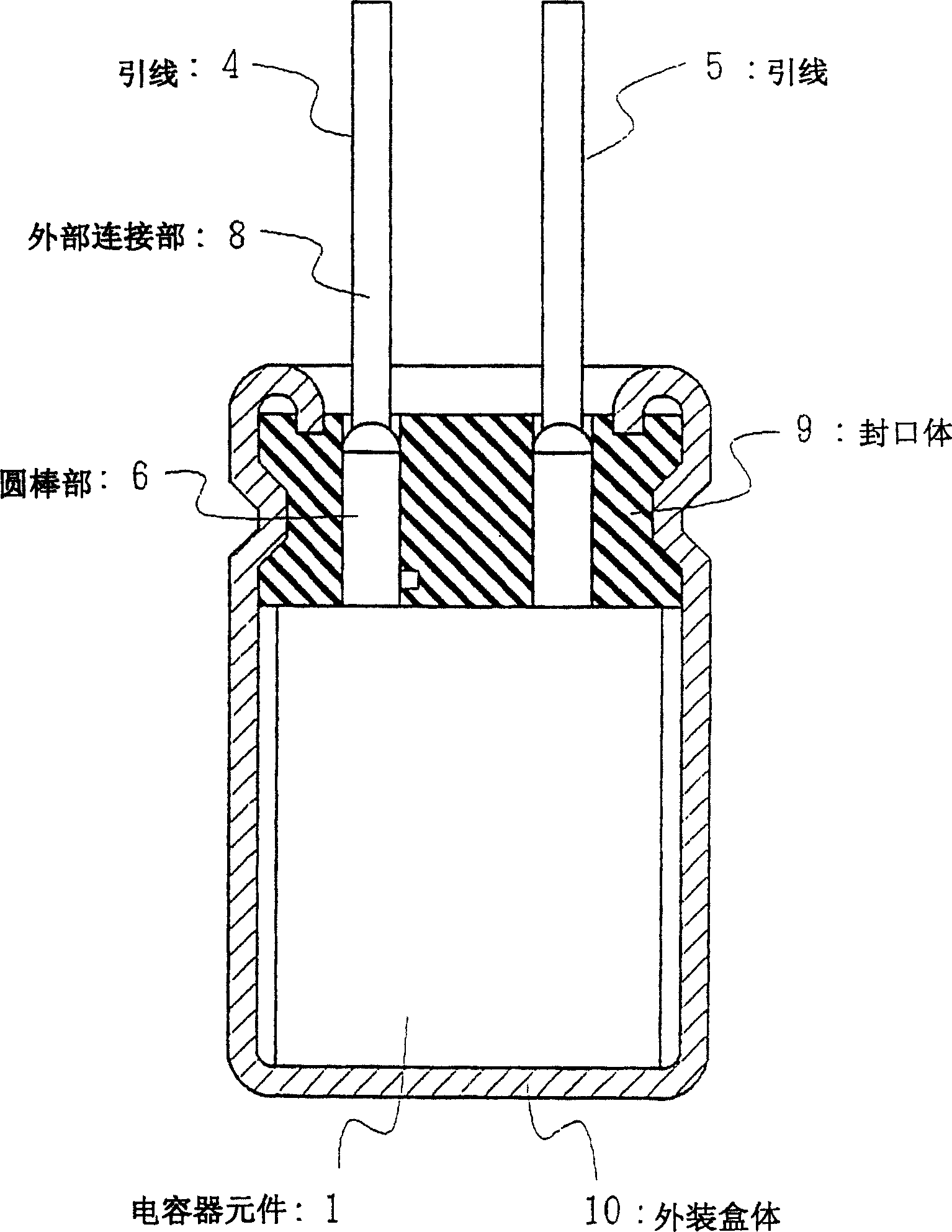

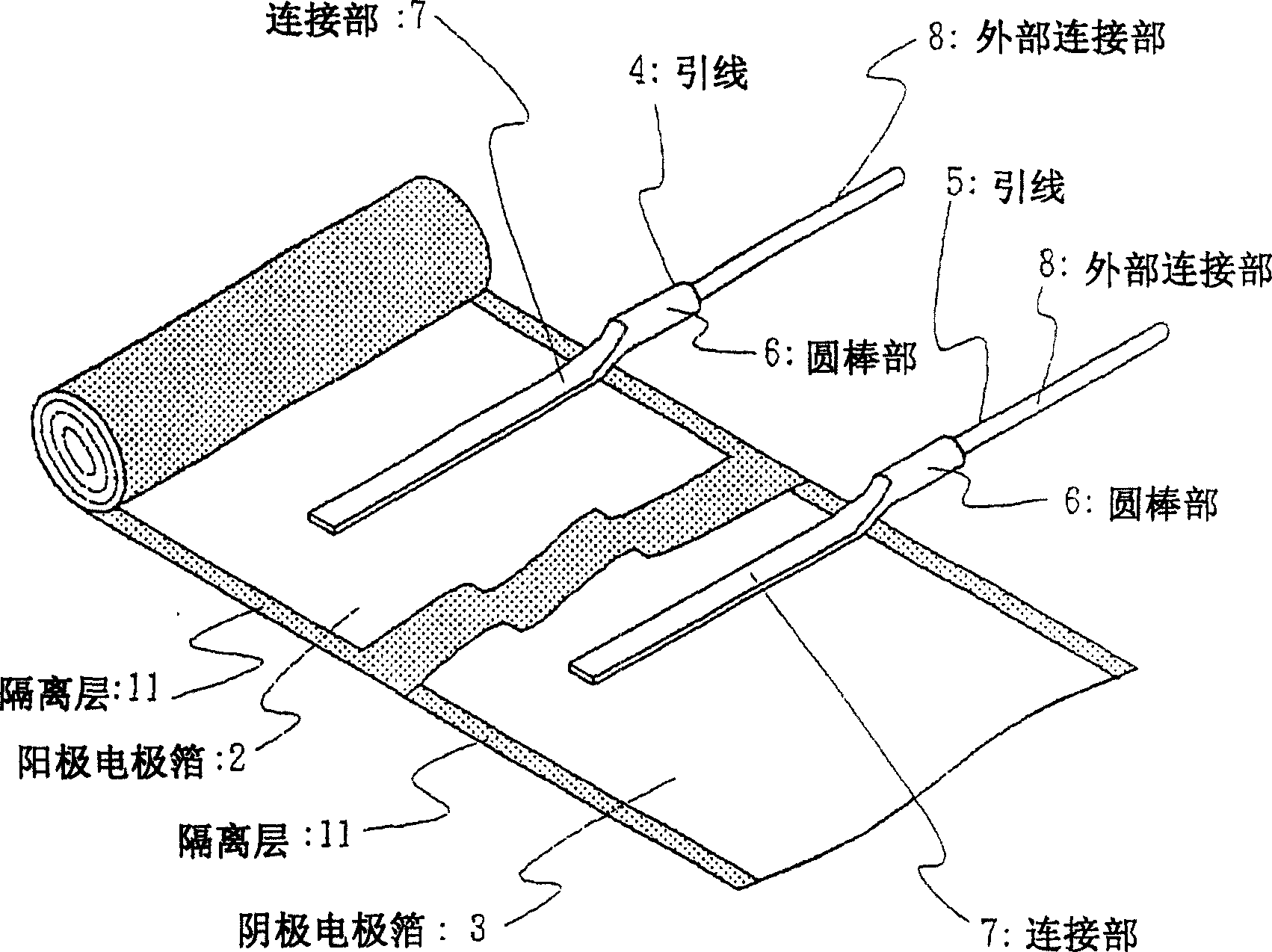

[0034] Next, the first invention will be described using examples. The construction of the electrolytic capacitor is the same as before, refer to figure 1 , figure 2 Be explained. The capacitor element 1 is formed by rolling an anode electrode foil 2 and a cathode electrode foil 3 with a separator 11 interposed therebetween. Also, if figure 2 As shown, the anode electrode foil 2 and the cathode electrode foil 3 are connected to the lead wire 4 for drawing out the anode and the lead wire 5 for drawing out the cathode, respectively.

[0035] These lead wires 4 and 5 are composed of a connection part 7 in contact with each foil, a round bar part 6 integrally formed with the connection part 7 , and an external connection part 8 bonded to the tip of the round bar part 6 . In addition, the connection part 7 and the round bar part 6 are made of 99% aluminum, and the external connection part 8 is made of copper-plated iron wire (hereinafter referred to as CP wire). On at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com