High-temperature aerobic fermentation of organic refuse material

A technology of organic waste and aerobic fermentation, applied in organic fertilizers, climate change adaptation, etc., can solve the problems of large area, low market value of end products, and many impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

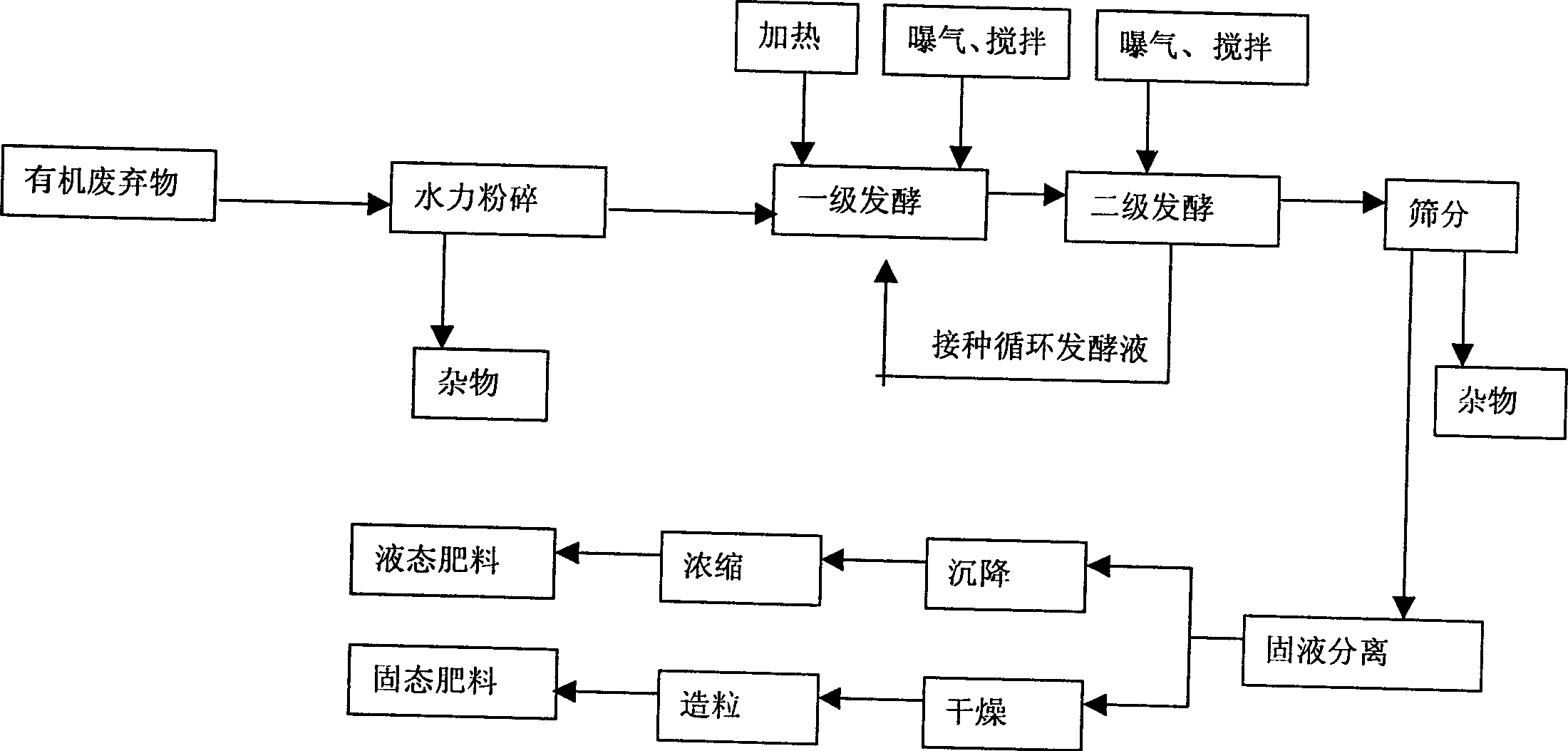

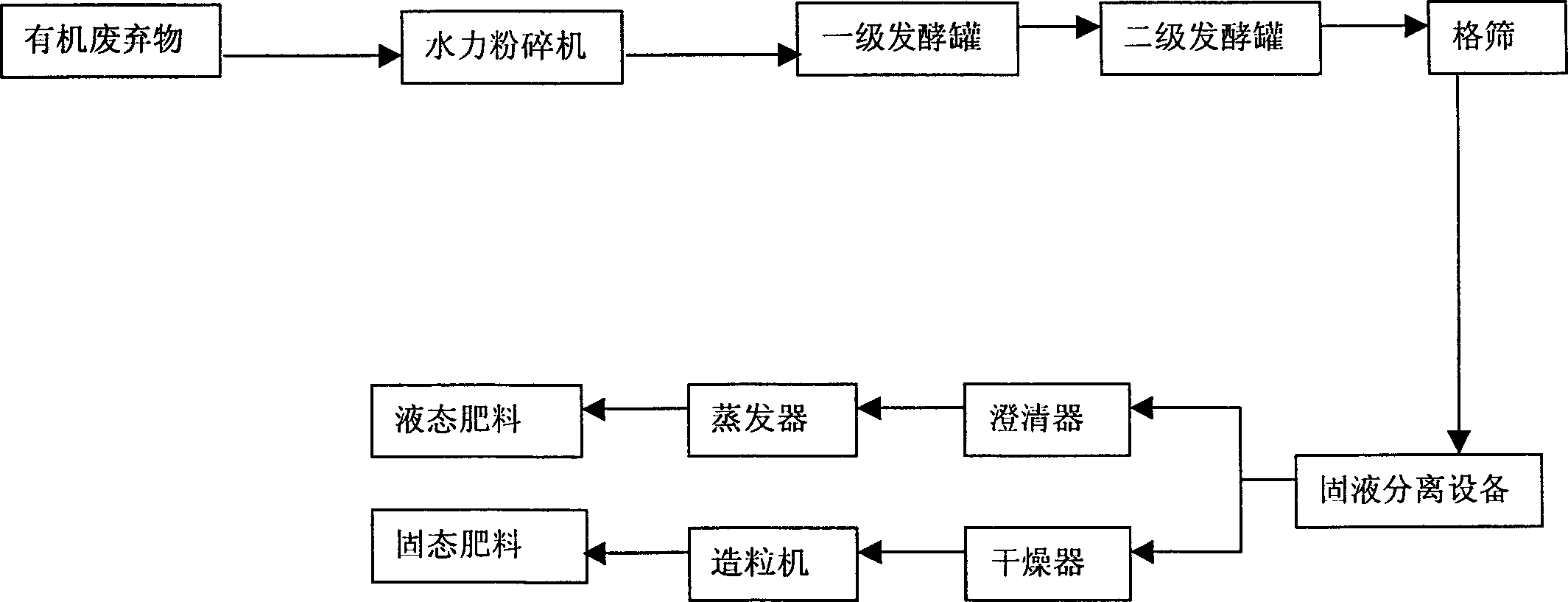

[0005] A kind of high-temperature aerobic fermentation process of organic waste of the present invention is as follows:

[0006] Organic waste is processed by a hydraulic pulverizer, which can pulverize biodegradable substances into a homogenate and use it as a raw material for biological fermentation. Because it is under hydraulic conditions, not only can the bio-organic matter be made into a homogenate, but also some stones, sediment, glass, metal, etc. removed from the surface. Wet sorting not only has high sorting efficiency, but also produces no dust and has little environmental pollution. Hydraulic pulverization can more thoroughly sort the sundries in organic waste. After the homogenate treated by the hydraulic pulverizer, the process parameters are adjusted at the same time, so that the pH is between 6-9, the C / N is between 12:1-30:1, and the solid content is controlled at about 6-12%; then enter In the primary fermentation tank, the temperature of the slurry in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com