Reciprocating compressor for compressing refrigerant

A compression refrigeration and reciprocating technology, applied in the direction of liquid variable displacement machinery, mechanical equipment, machines/engines, etc., can solve the problems of refrigerant heat transfer performance and lubrication performance degradation, wear of friction parts, damaged parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

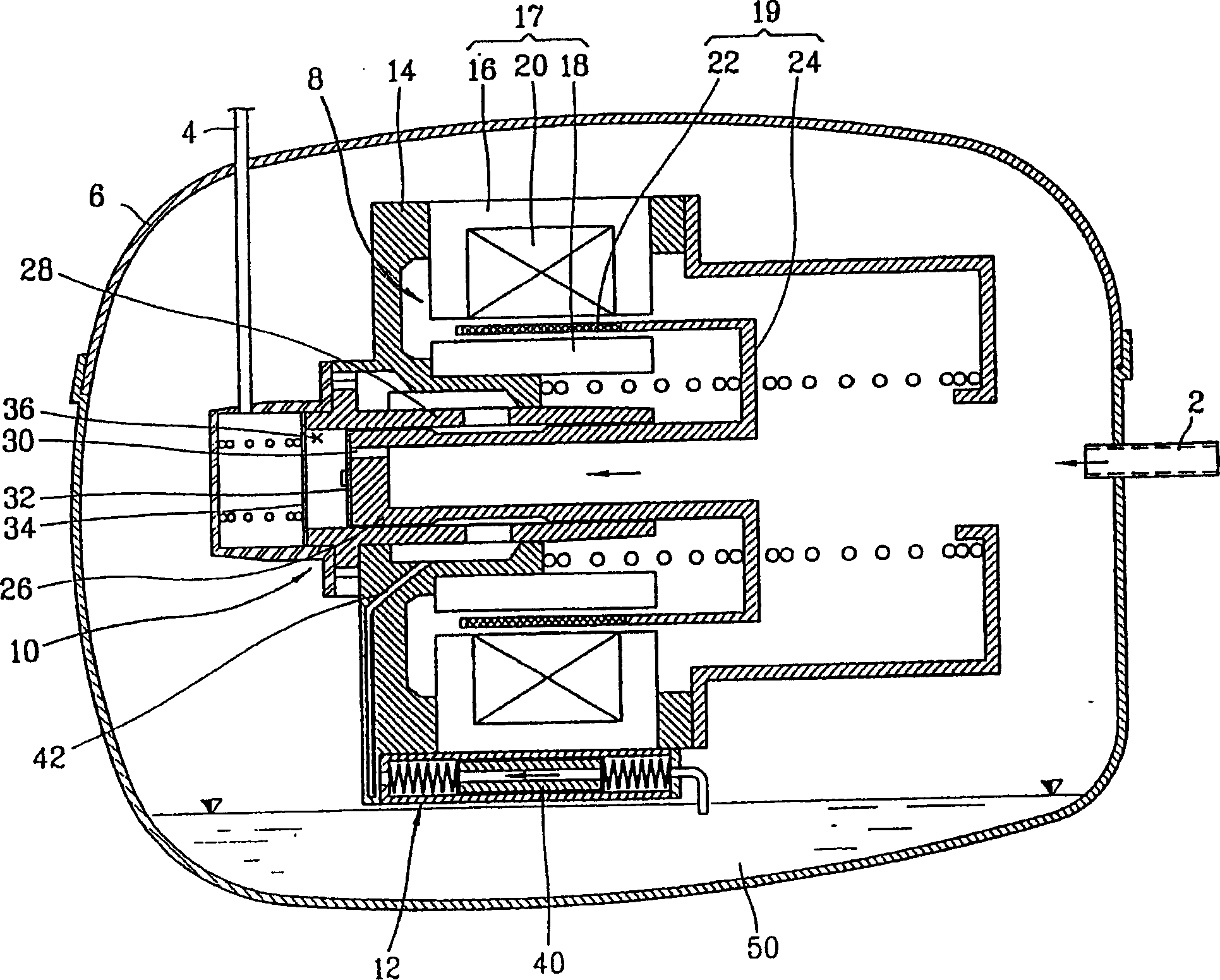

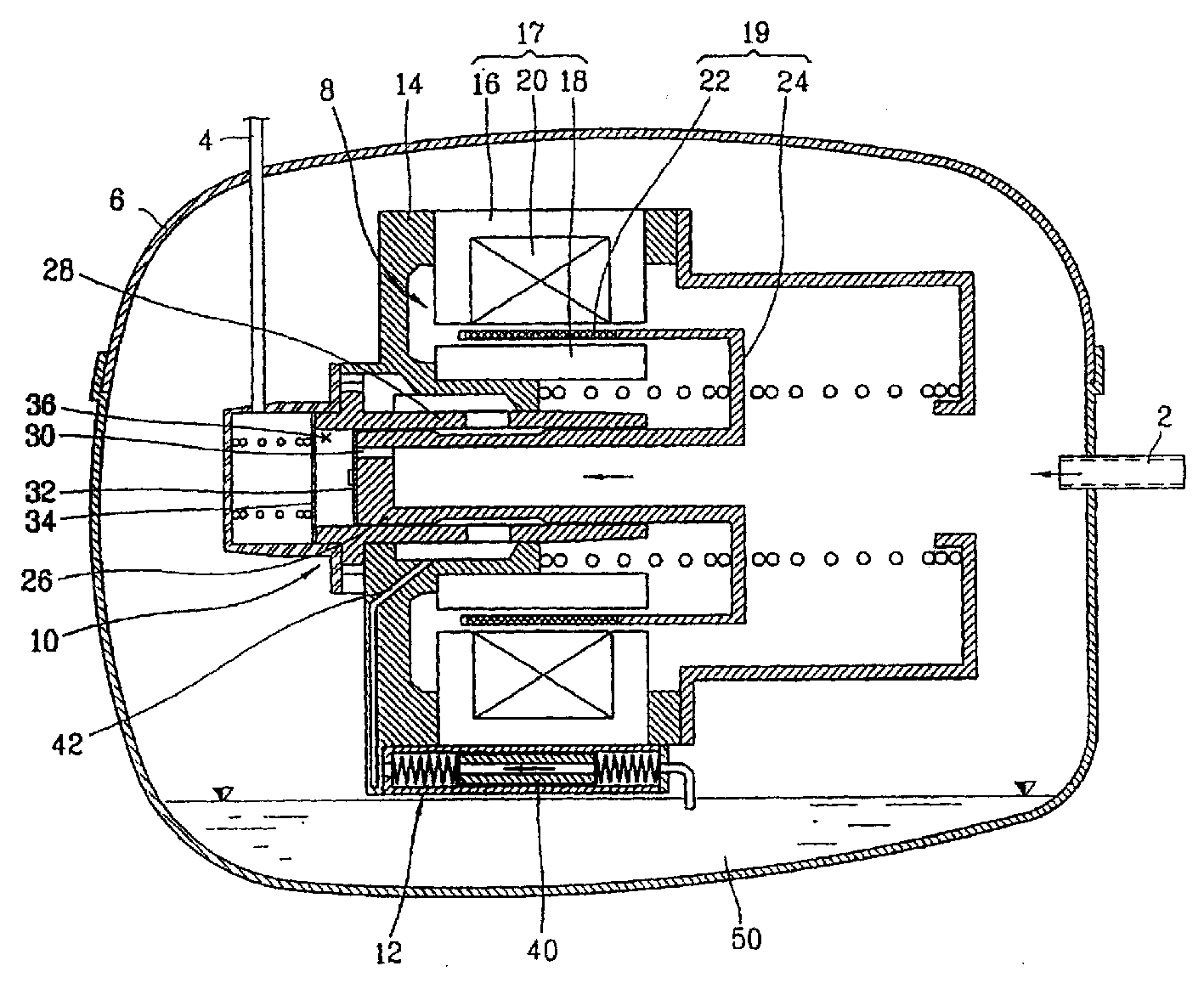

[0027] figure 1 is a cross-sectional view of a conventional reciprocating compressor used to compress refrigerant.

[0028] Such as figure 1 As shown, a conventional reciprocating compressor includes: a sealed shell 6, a suction pipe 2 for sucking in refrigerant and a discharge pipe 4 for discharging compressed refrigerant connected to it, and a reciprocating force generated inside the casing 6 The driving unit 8, the compression unit 10 for bearing the reciprocating force generated by the driving unit 8 and performing the compression operation on the refrigerant; the lubrication unit 12 for performing the lubrication operation on the moving parts of the driving unit 8 and the compression unit 10 .

[0029] The drive unit 8 includes: a cylindrical outer stator 16 fixed by a bracket 14 fixed in the sealed casing; an inner stator 18 arranged to have an air gap with the inner peripheral surface of the outer stator 16; a winding coil 20 wound around the outer stator 16, Electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com