Rolling press treating method for surface protruding on metal material

A metal material and processing method technology, which is applied in the field of rolling processing of protrusions on the surface of metal materials, can solve the problems of difficult control, difficult processing, and high requirements, and achieves good controllability of process parameters, prevention of gas pollution, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

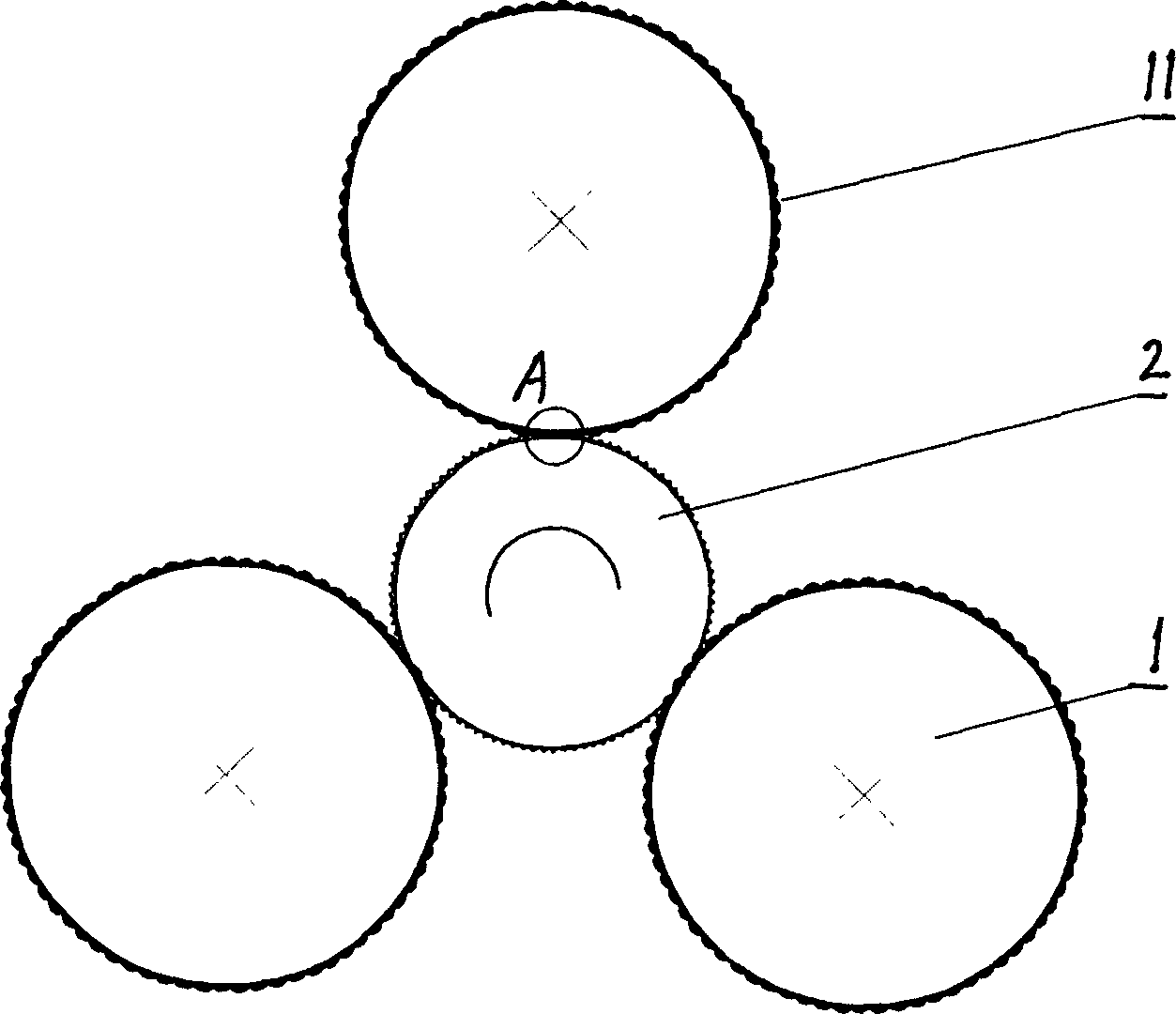

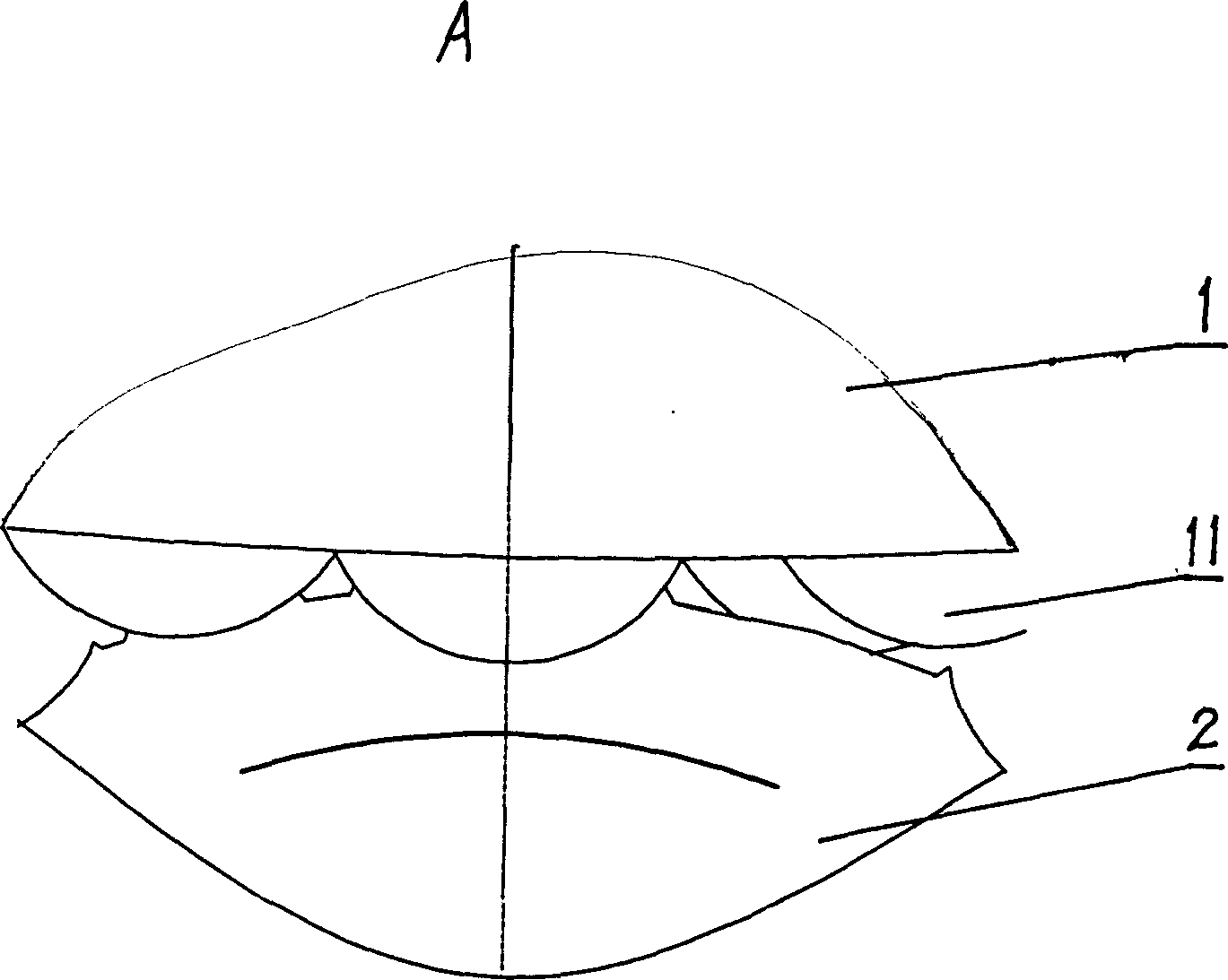

[0013] Embodiment 1 of the present invention is to carry out rolling nanocrystallization treatment on the surface of the outer cylindrical surface of the 20 steel annular workpiece.

[0014] Original state: annealed state, average grain size 26um, workpiece size Φ200×20×50, treatment process and control conditions: clean workpiece surface—rolling chamber air pressure 6.67×10 -2 Pa——Three rolling die treatment, pre-rolling processing process: two rolling dies are distributed with protrusions with a diameter of 2mm, and their depth of pressing into the workpiece is 0.02mm, and the other rolling die is distributed with a diameter of 20mm The protrusion, which is pressed into the workpiece at a depth of 0.005mm, and the plastic deformation rate of rolling is 7×10 per second 3 , it takes 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com