Processing method of ceramic dividing disc and its device

A processing device and processing method technology, applied in the direction of ceramic molding machines, sorting, manufacturing tools, etc., can solve the problems of high manufacturing costs, achieve the effects of ensuring processing accuracy, ensuring concentricity, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

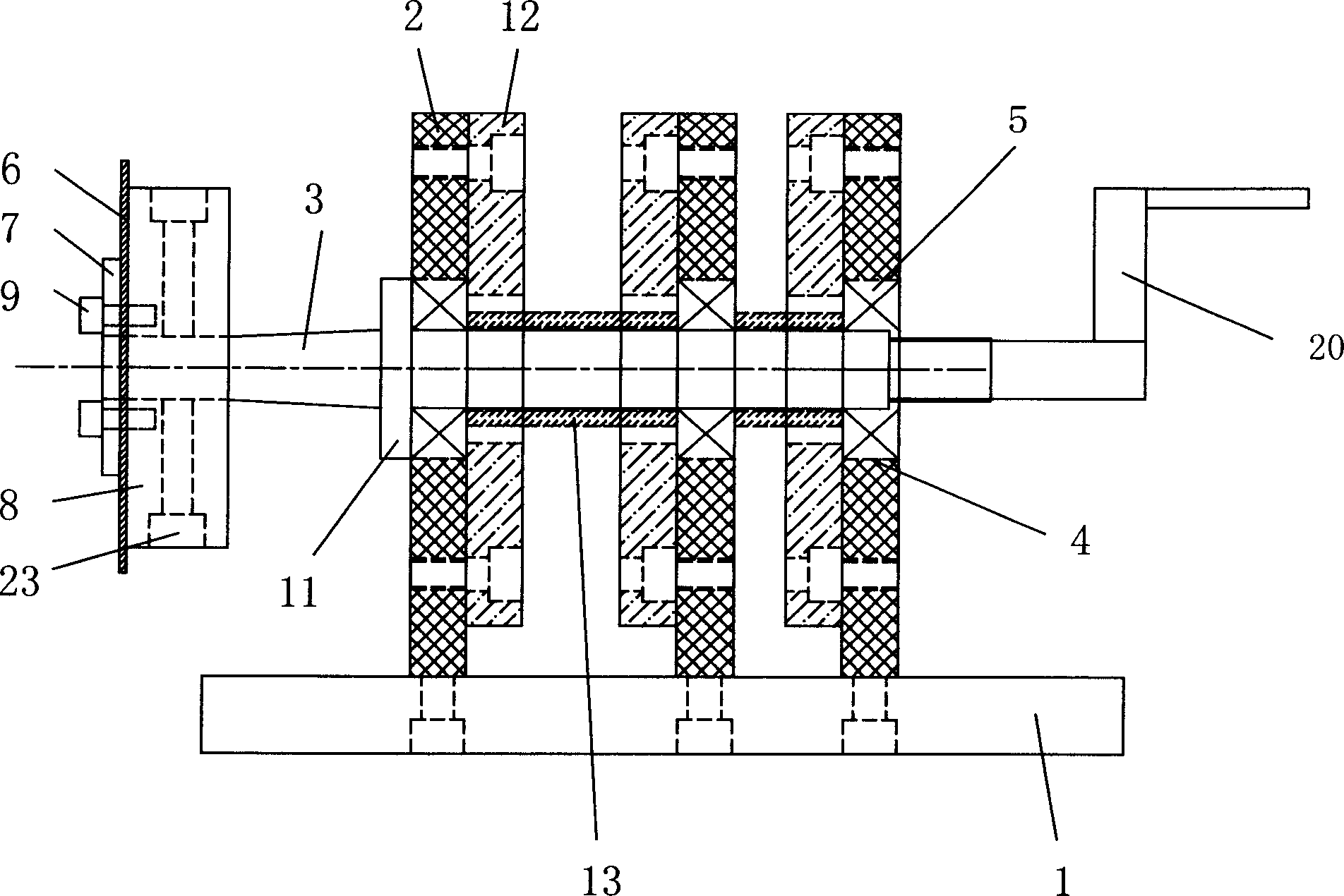

[0024] Embodiment: a kind of processing method of ceramic index plate, comprises the following steps:

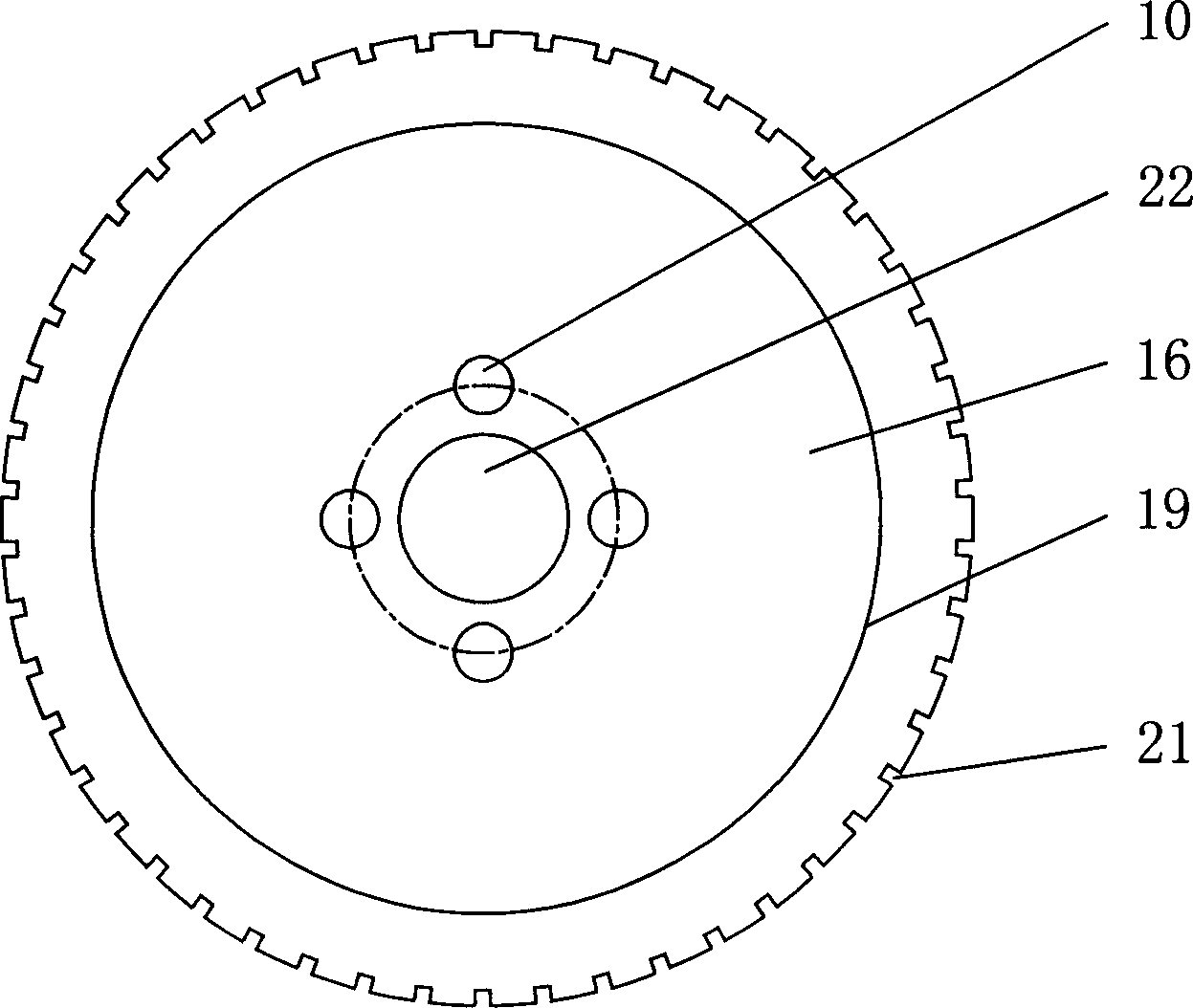

[0025] A. The ceramic indexing plate blank 6 with a certain outer circle, shaft hole 22 and thickness is processed by injection method;

[0026] B. Use a drilling machine to process the installation hole 10 around the shaft hole 22 to the required size of the part;

[0027] C. Roughly grind the planes on both sides of the blank 6 on a surface grinder;

[0028] D. Taking the installation hole 10 as the positioning reference, process the shaft hole 22 to the required size of the part;

[0029] E. Finely grind the thickness to the required size of the part on a surface grinder;

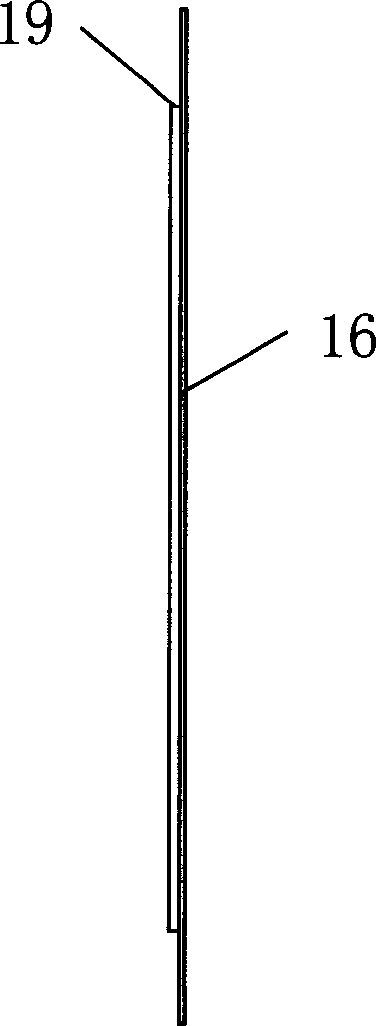

[0030] F. Clamp the blank 6 on the special tooling to roughly grind the outer circle, then grind the step 19 to the required size of the part, and then finely grind the outer circle to the required size of the part;

[0031] G. Equivalent wheel 14, positioning pin 17, fixed arm 18 are installed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com