Transformer cannula test device and its test method

A technology of transformer bushing and test device, applied in the field of transformers, can solve the problems of quality and safety hazards, and achieve the effect of guaranteeing quality, guaranteeing use and guaranteeing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

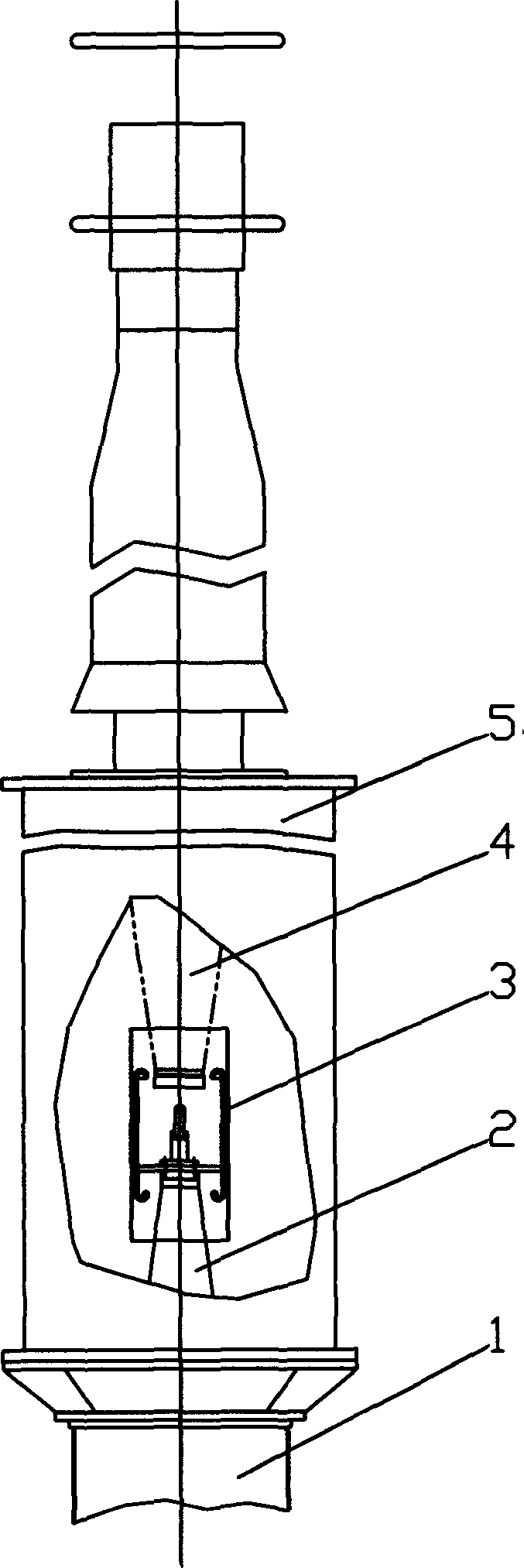

[0028] Such as figure 1 As shown, the composition of the present invention is as follows: the top of the oil-sulfur hexafluoride bushing 2 is electrically connected to the tail of another oil-air bushing 4 of the same voltage level, and a pressure equalizing shield 3 is provided at the joint of the two bushings. The outside of the shielding cover 3 is provided with an external rising seat 5 to cover and seal it for oil loading, and the lower part of the transformer oil-sulfur hexafluoride bushing is installed on the high-voltage outgoing line rising seat 1 .

[0029] The top of the oil-sulfur hexafluoride bushing 2 is provided with a wiring board, and the pressure equalizing shield 3 is provided with a wiring board.

Embodiment 2

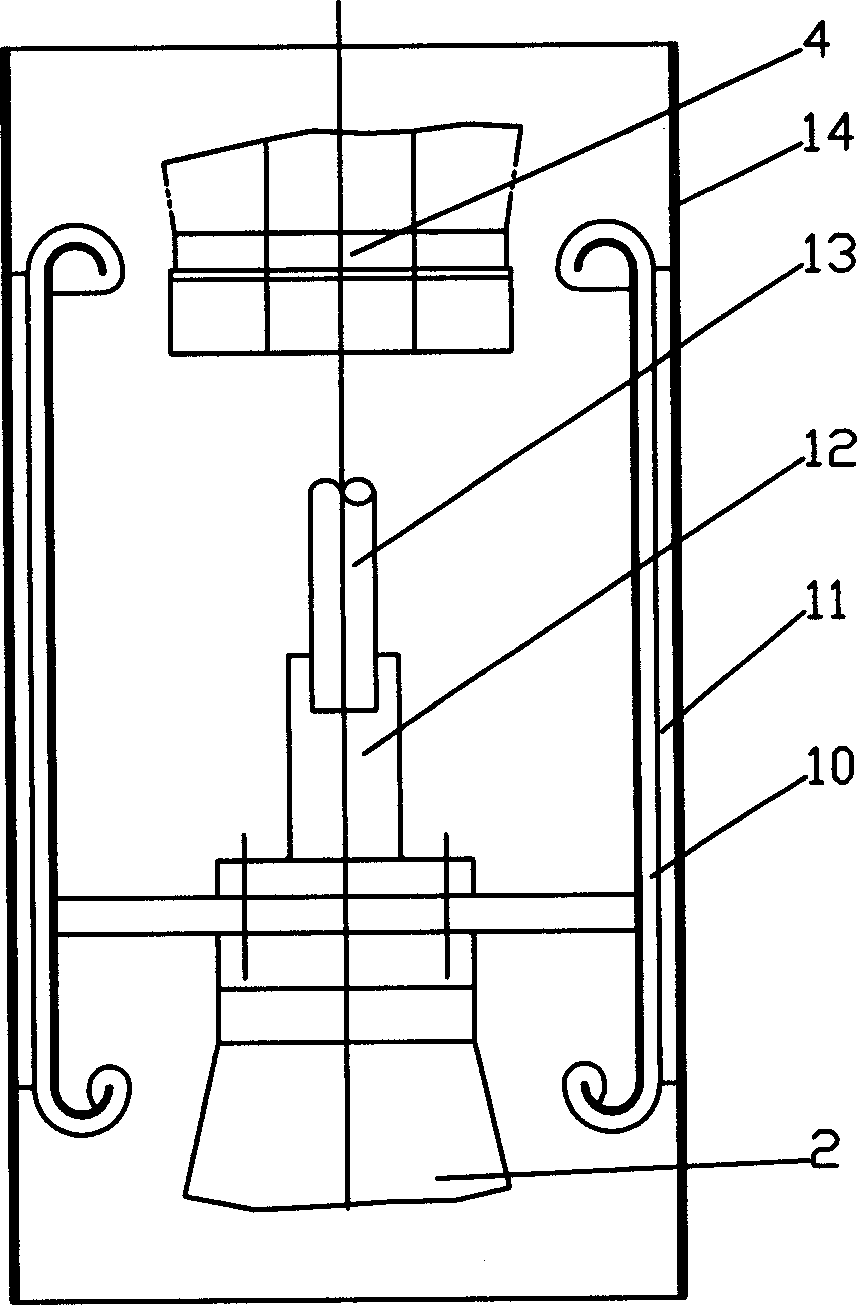

[0031] Such as image 3 As shown, it is a diagram of an insulation structure at the junction of two bushings, oil-sulfur hexafluoride

[0032] The top of the bushing 2 is electrically connected to the tail of another oil-air bushing 4 of the same voltage level through the connector 12 and the lead cable 13. The joint of the two bushings is provided with copper shielding and outsourcing insulation 10, and the copper shielding and outsourcing insulation 10 A strut 11 is provided on the outer wall of the housing, and an insulating cylinder 14 is provided outside it.

Embodiment 3

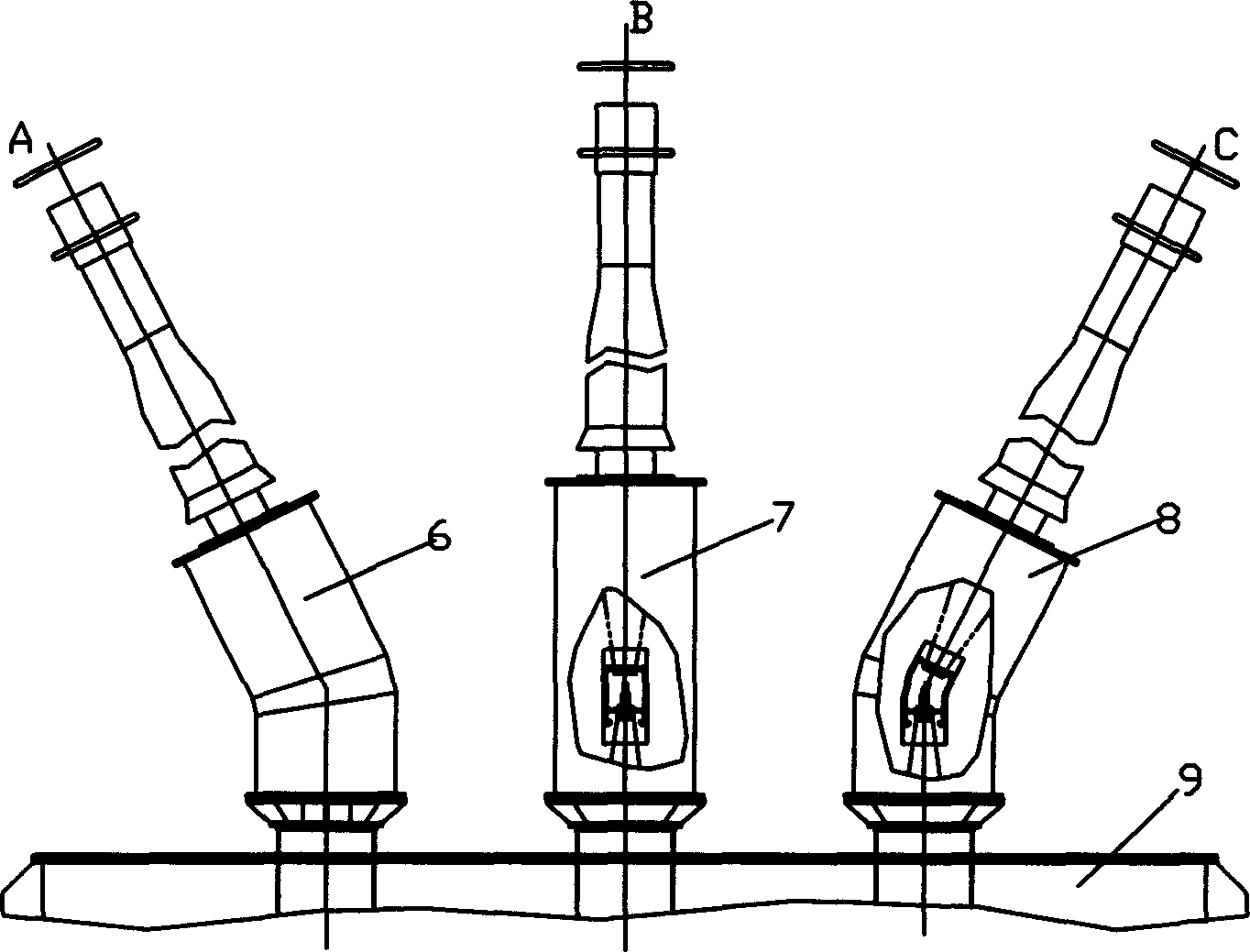

[0034] Such as Figure 4 As shown, it is another insulation structure diagram of the junction of the two bushings. In order to meet the installation requirements of the three-phase transformer test bushing, the specific connection method is basically the same as that of Example 2, the difference lies in the lead cable 13, copper shielding and outsourcing The insulation 10 and the insulation cylinder 14 are respectively in a corresponding curved shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com