Method for preparing Mg0.8CUO.2B2 superconduct bulk material

A technology of mg0.8cu0.2b2 and superconducting blocks, which is applied in the usage of superconducting elements, the manufacture/processing of superconducting devices, superconducting devices, etc., can solve the problems of complex reaction process, large energy consumption, and large investment in equipment , to achieve the effect of rapid reaction process, energy saving and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

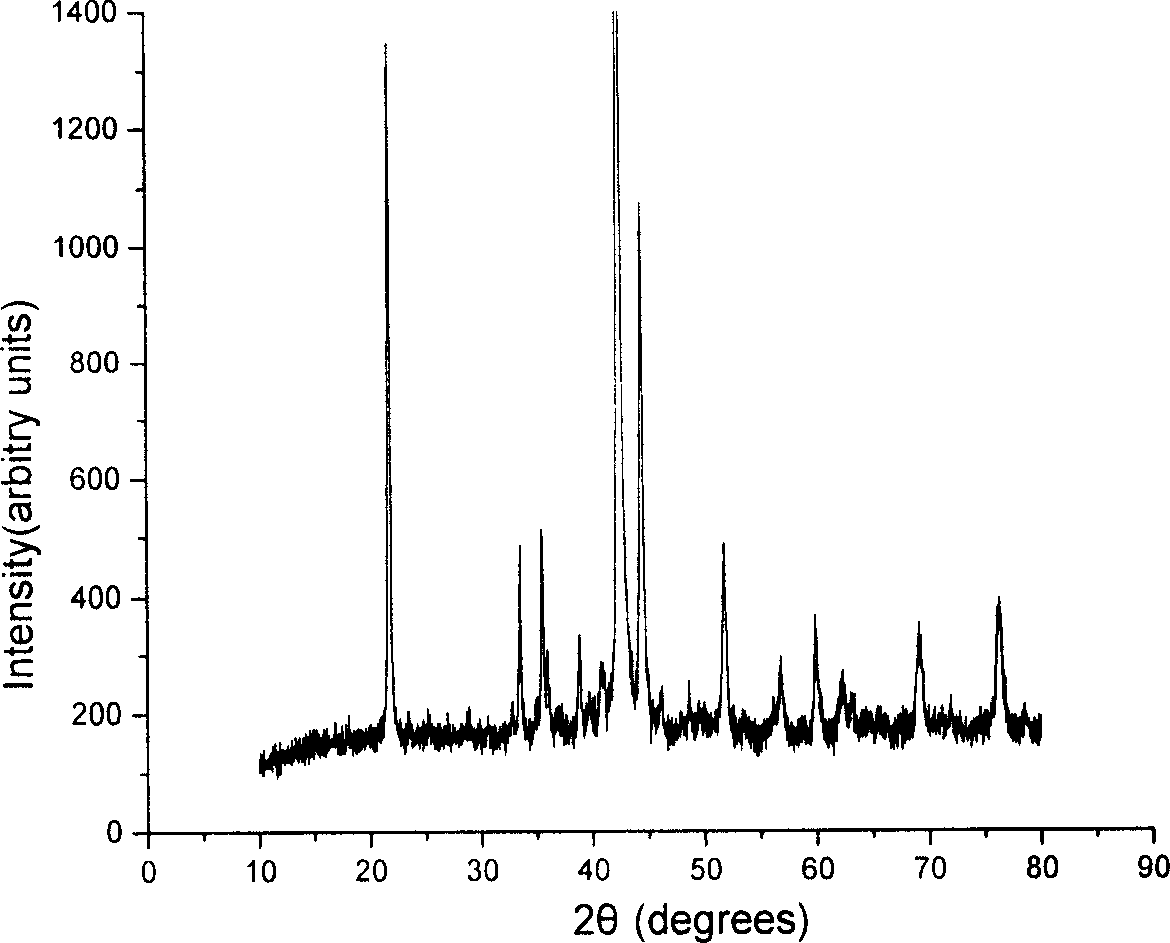

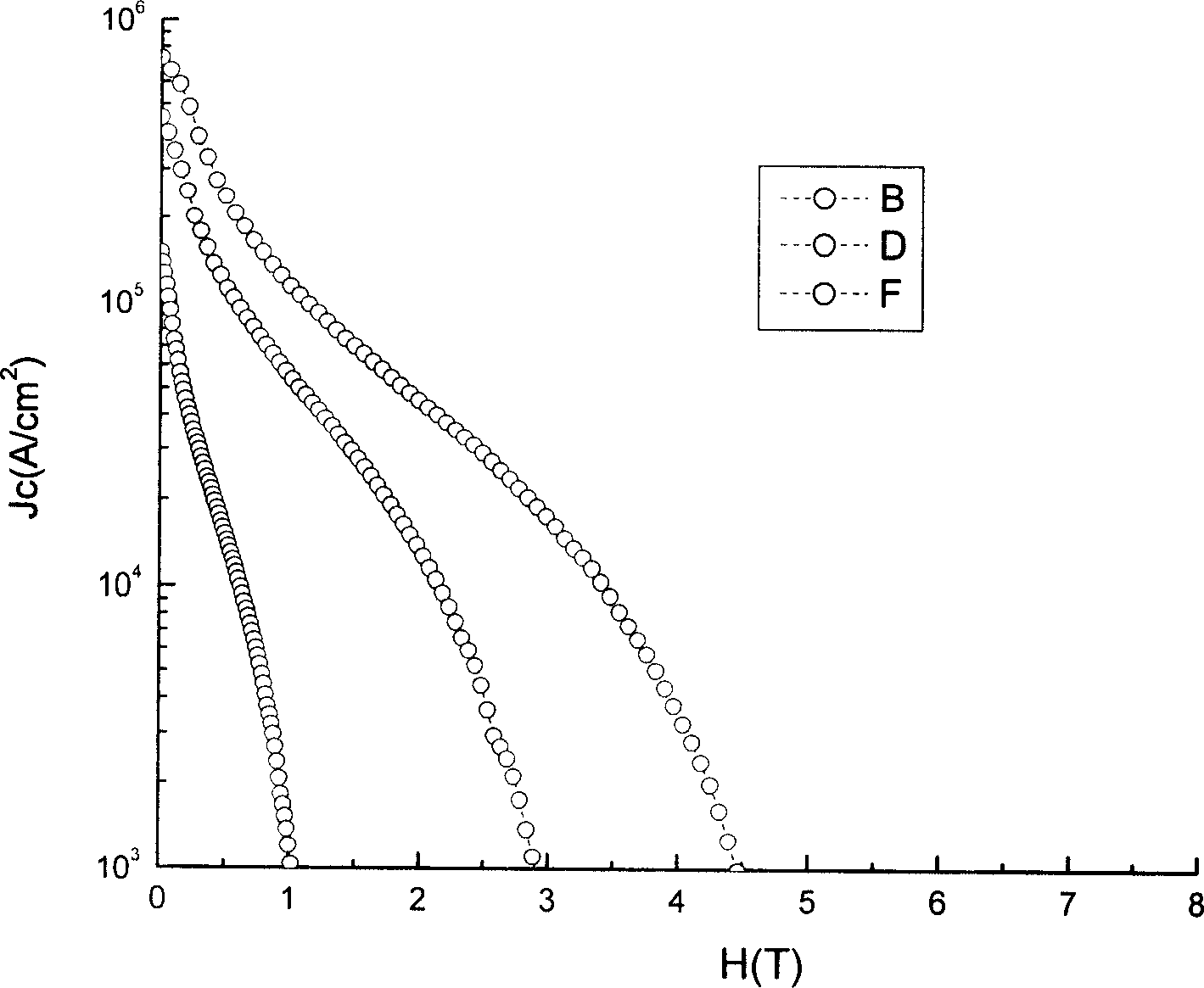

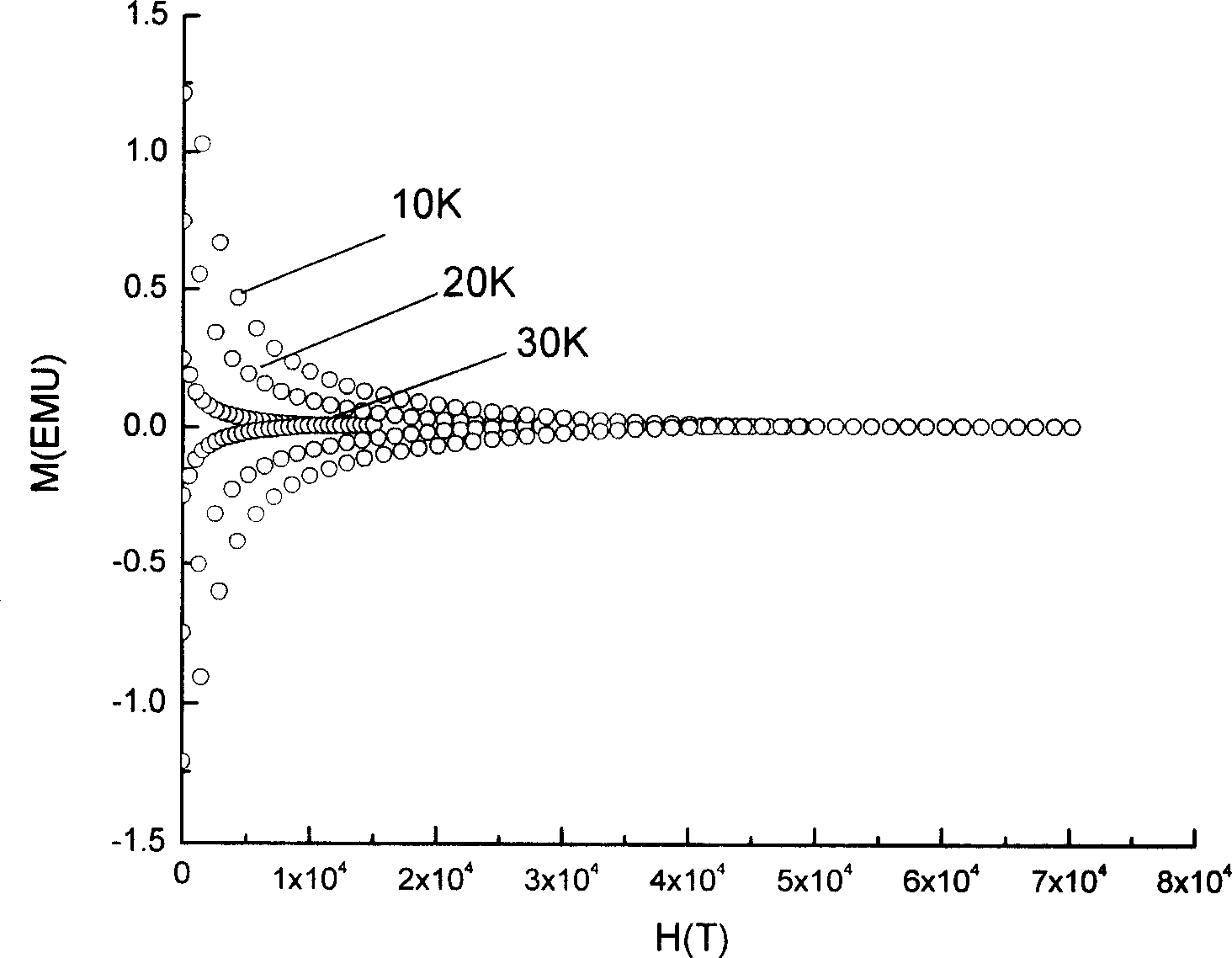

[0013] The present invention adopts powders of Mg and B. First, the powders of Mg, Cu and B are weighed in a stoichiometric ratio of 0.8:0.2:2, and then 1% of the weight of the weighed Mg is added. Then put the weighed Mg, Cu powder and B powder in a ball mill for grinding and mixing. The speed of the ball mill is 200 revolutions per minute, and the time for ball milling is 2 hours. The grinding balls are mixed with Mg, Cu, and B powders. The total weight ratio of the materials is 35-40:1. Press the milled powder into a sheet or column blank under a pressure of 150Mpa, and put it into a vacuum furnace. The vacuum furnace is evacuated or filled with inert gas, and preheated at a heating rate of 30℃ / min. Use an arc to ignite the billet at the top of the billet at ℃. When the ignition temperature reaches 700°C, the arc is extinguished. The reaction is allowed to continue for 3 seconds. The adiabatic temperature is 1461°C. Mg can be obtained by natural cooling to room temperature. 0.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com