Method of forming capacitor of semiconductor device

A technology for semiconductors and capacitors, applied in the field of capacitors, which can solve the problems of low crystallization temperature, increased leakage current, difficult to use as leakage current characteristics and charging capacitor dielectric film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

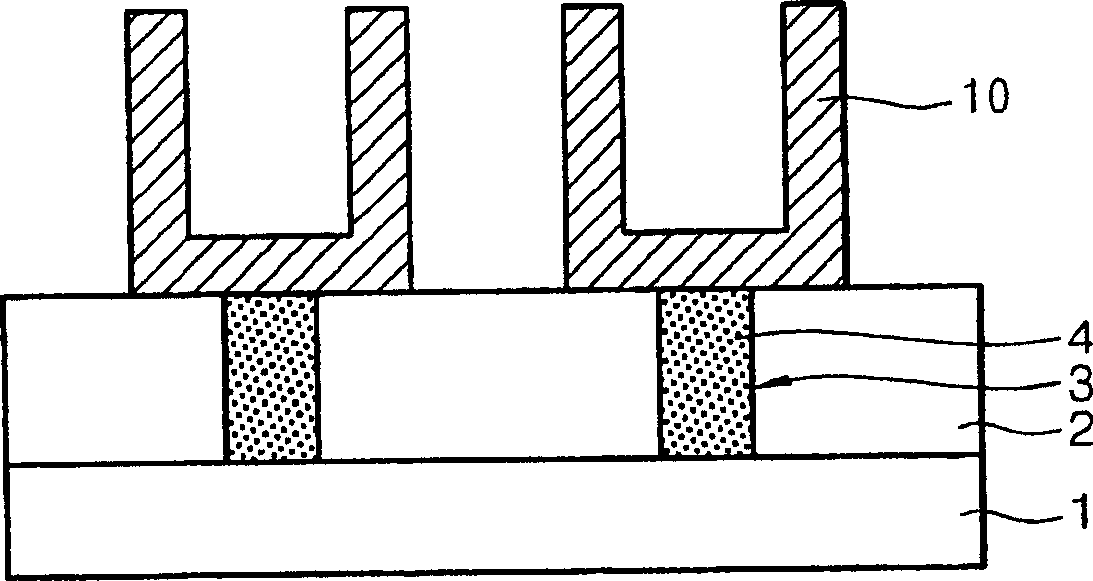

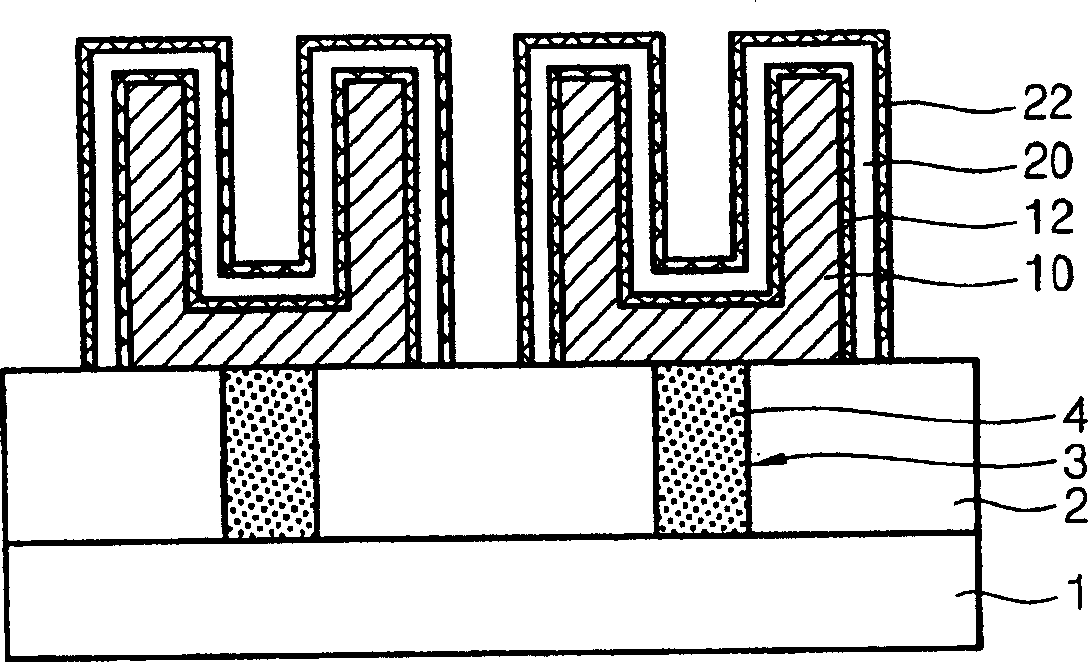

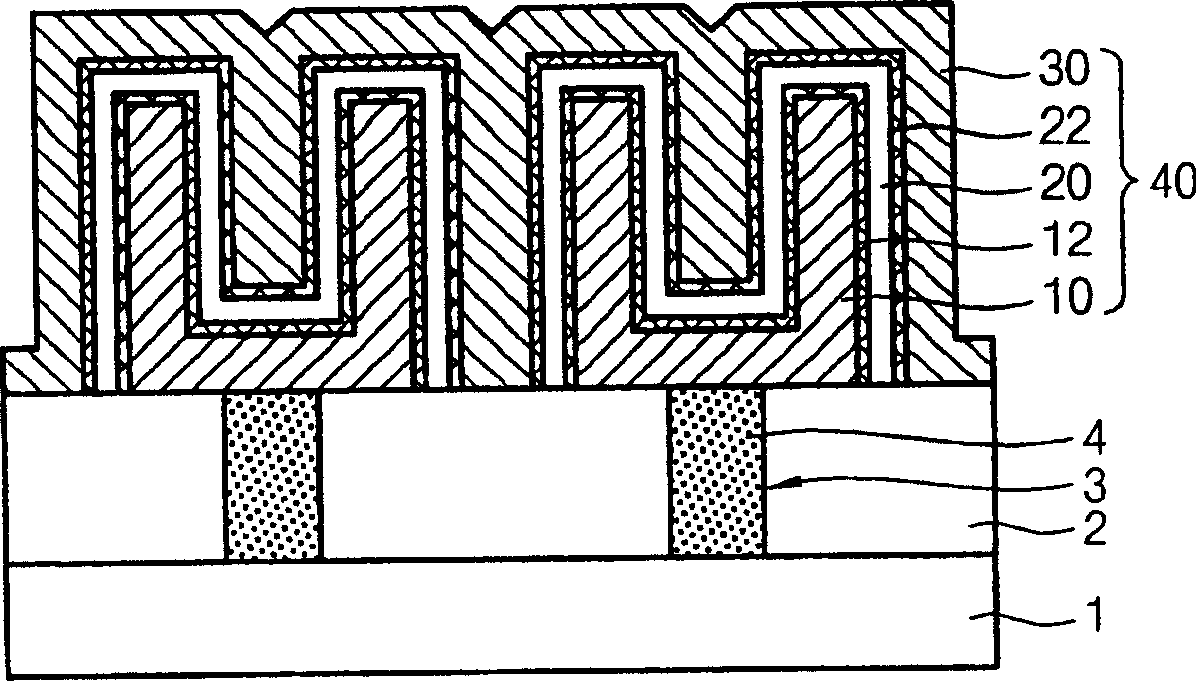

[0019] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0020] Involving the technical principle of the present invention, the present invention utilizes nitrided La 2 o 3 The dielectric film forms a capacitor as a dielectric film, thereby overcoming the Al 2 o 3 Dielectric properties of films and HfO 2 The limitation of the thermal stability of the film. In addition, in the formation of nitrided La 2 o 3 film process, the La 2 o 3 After film deposition, by means of NH 3 La 2 o 3 The low-temperature plasma nitridation performed on the surface of the film introduces nitrogen into La 2 o 3 film, La-O-N bonds are formed.

[0021] In this case, since La 2 o 3 Nitriding of the surface of the film, La 2 o 3 The crystallization temperature of the film itself is increased, and impurities are also prevented from diffusing from the lower electrode and the upper electrode to the La 2 o 3 inside the membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com