Modified li-Mg-Ni composite oxides and manufacturing method, Li secondary battery and positive electrode active material

A composite oxide and lithium secondary battery technology, which is applied in secondary batteries, active material electrodes, nickel compounds, etc., can solve the problems of large manganese ion dissolution and discharge capacity, which is only a fraction of the theoretical amount, etc. Achieve excellent cycle characteristics and coulombic efficiency, and inhibit the effect of stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] (first process)

[0119] The above modulated LiMn 1.5 Ni 0.5 o 4 200 g each and 1 g each metal oxide, and mix well with a household mixer for 60 seconds, thereby making each metal oxide adhere to the LiMn 1.5 Ni 0.5 o 4 particle surface. In addition, the BET specific surface area after the first step was measured, and the results are shown in Table 2.

[0120] (second process)

[0121] Next, heat treatment was performed at 500° C. for 5 hours in an alumina furnace. After cooling, crushing and screening are carried out to obtain a modified lithium-manganese-nickel-based composite oxide. Table 2 shows various physical properties of the obtained modified lithium-manganese-nickel composite oxide. figure 1 and figure 2 Electron micrographs of the modified lithium-manganese-nickel-based composite oxides obtained in Example 1 and Example 2 are shown, respectively. Furthermore, the amount of manganese elution was measured in the same manner as above. As a result, t...

reference example 1

[0123] The lithium-manganese-nickel-based composite oxide prepared above without coating treatment was used as a reference sample.

[0124] Metal oxide

Physical properties of lithium-manganese-nickel-based composite oxides

Specimen type

Compounding amount

(weight%)

BET specific surface area

(m 2 / g)

The average particle size

(μm)

Example 1

Sample 1

0.5

0.52

10.6

Example 2

Sample 2

0.5

0.73

10.0

Example 3

Sample 3

0.5

0.64

10.3

[0125] (performance evaluation)

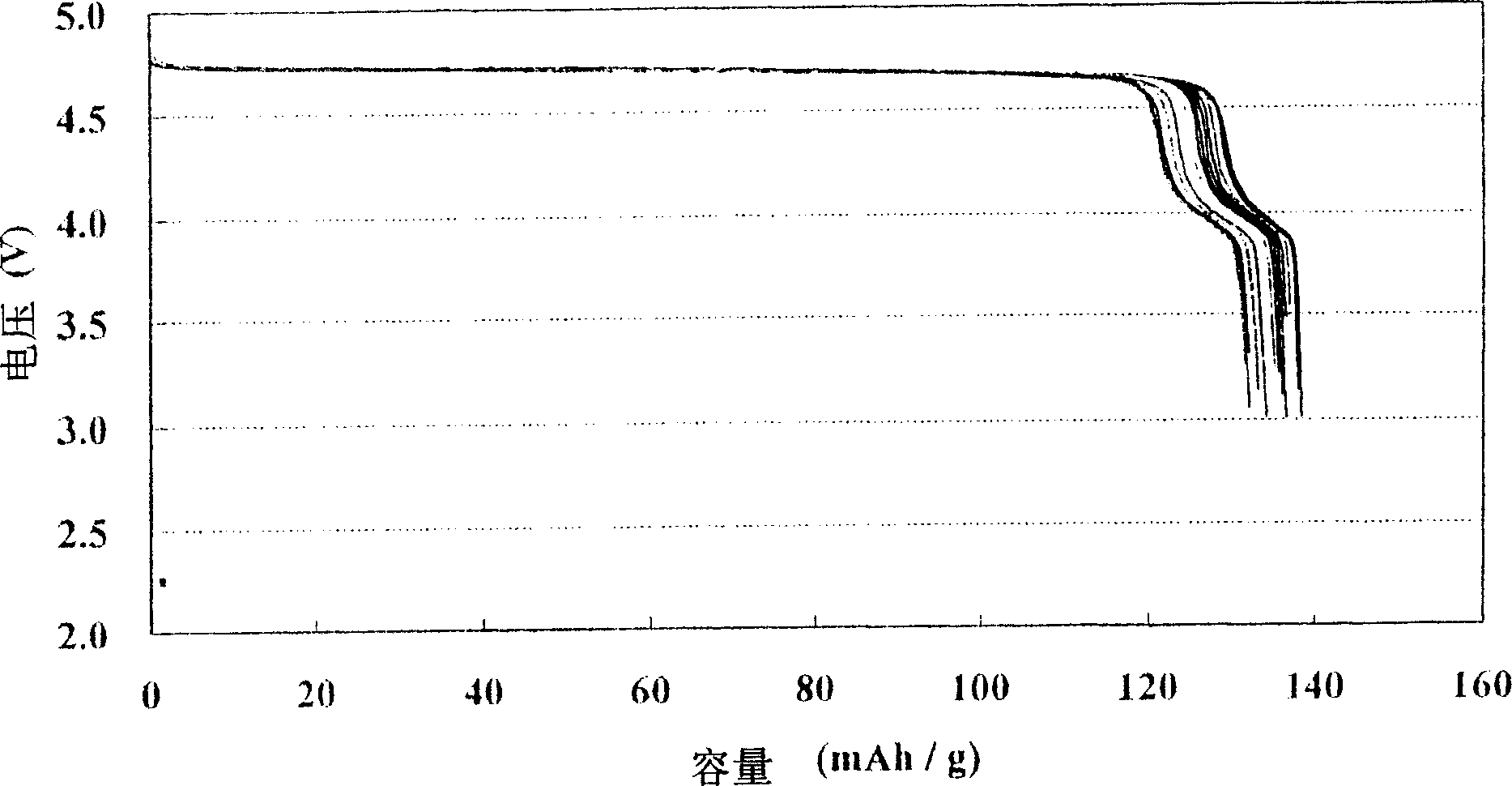

[0126] Using the modified lithium-manganese-nickel-based composite oxide obtained in Examples and the lithium-manganese-nickel-based composite oxide of Reference Example 1 as positive electrode active materials, a lithium secondary battery was produced. The initial discharge capacity of the battery, the coulombic efficiency at the 10th cycle, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com