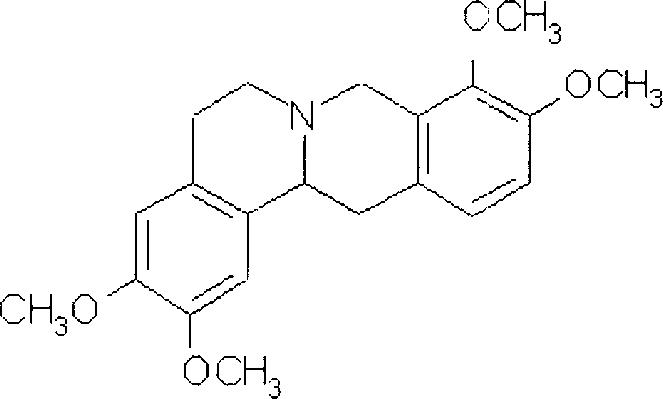

Slow release tablet of rotundine and production process

A technology of sustained-release preparations and sustained-release parts, which is applied in the field of new dosage forms - Rotundine sustained-release tablets, which can solve problems such as unsuitable for taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the sustained-release preparation containing 105mg rotundine

[0017] Immediate release part: rotundine 45mg, polyvinylpyrrolidone 6mg, microcrystalline cellulose 40mg, lactose 20mg, magnesium stearate 1mg.

[0018] Mix the above-mentioned amount of rotundine, polyvinylpolypyrrolidone, microcrystalline cellulose, and lactose in equal amounts, add an appropriate amount of 10% povidone aqueous solution, and make a soft material, pass through a 12-20 mesh sieve Granulate, dry in an oven at 50-60°C, granulate, add the above-mentioned amount of magnesium stearate, mix well, analyze the content of the semi-finished product, and prepare the granules for later use.

[0019] Sustained-release part: 60mg of rotundine, 60mg of hydroxypropyl methylcellulose K4000, 30mg of L-tartaric acid, 2mg of magnesium stearate.

[0020] Mix the above amount of rotundine, hydroxypropyl methylcellulose K4000, and L-tartaric acid evenly, add 50% ethanol solution to make a soft mater...

Embodiment 2

[0022] Embodiment 2: the sustained release preparation of 120mg rotundine

[0023] Immediate release part: rotundine 30mg; polyvinylpyrrolidone 7mg, β-cyclodextrin 100mg, magnesium stearate 1mg.

[0024] Production process: Weigh 30 mg of rotundine, add ethanol to dissolve, add dropwise to 100 mg of β-cyclodextrin (β-cyclodextrin: water = 20:80w / v) solution heated to 70-80°C, and stir for 2 hours , filter the precipitate, and dry it in a 50-60°C oven to obtain a mixture of rottondine and β-cyclodextrin. Mix with the above-mentioned amount of polyvinylpolypyrrolidone and process according to the method in Example 1.

[0025] Sustained-release components: rotundine 90mg, hydroxypropyl methylcellulose K 4000 90mg, L-tartaric acid 45mg, magnesium stearate 2mg are processed by the method described in Example 1 to obtain the sustained-release preparation of 120mg rotundine / tablet.

Embodiment 3

[0026] Example 3: Sustained release formulation of rotundine 210 mg.

[0027] Immediate-release components: 90 mg of rotundine, 12 mg of polyvinylpyrrolidone, 80 mg of microcrystalline cellulose, 40 mg of lactose, and 2 mg of magnesium stearate, processed according to the method of Example 1 to obtain immediate-release component granules.

[0028] Sustained release components: rotundine 120mg, hydroxypropyl methylcellulose K 4000 120mg, L-tartaric acid 60mg, magnesium stearate 4mg, according to embodiment 1 sustained-release component processing and tabletting processing method, obtain the sustained-release preparation of 210mg rotundine / tablet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com