Jade simulated glass cinerary urn and manufacturing process thereof

A manufacturing process and a columbarium technology, which is applied in the field of imitation jade glass columbarium and its manufacturing process, can solve the problems of complex manufacturing process, poor aesthetics, and easy decay of wooden columbaria, and achieve beautiful appearance, low production cost, and high manufacturing efficiency. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

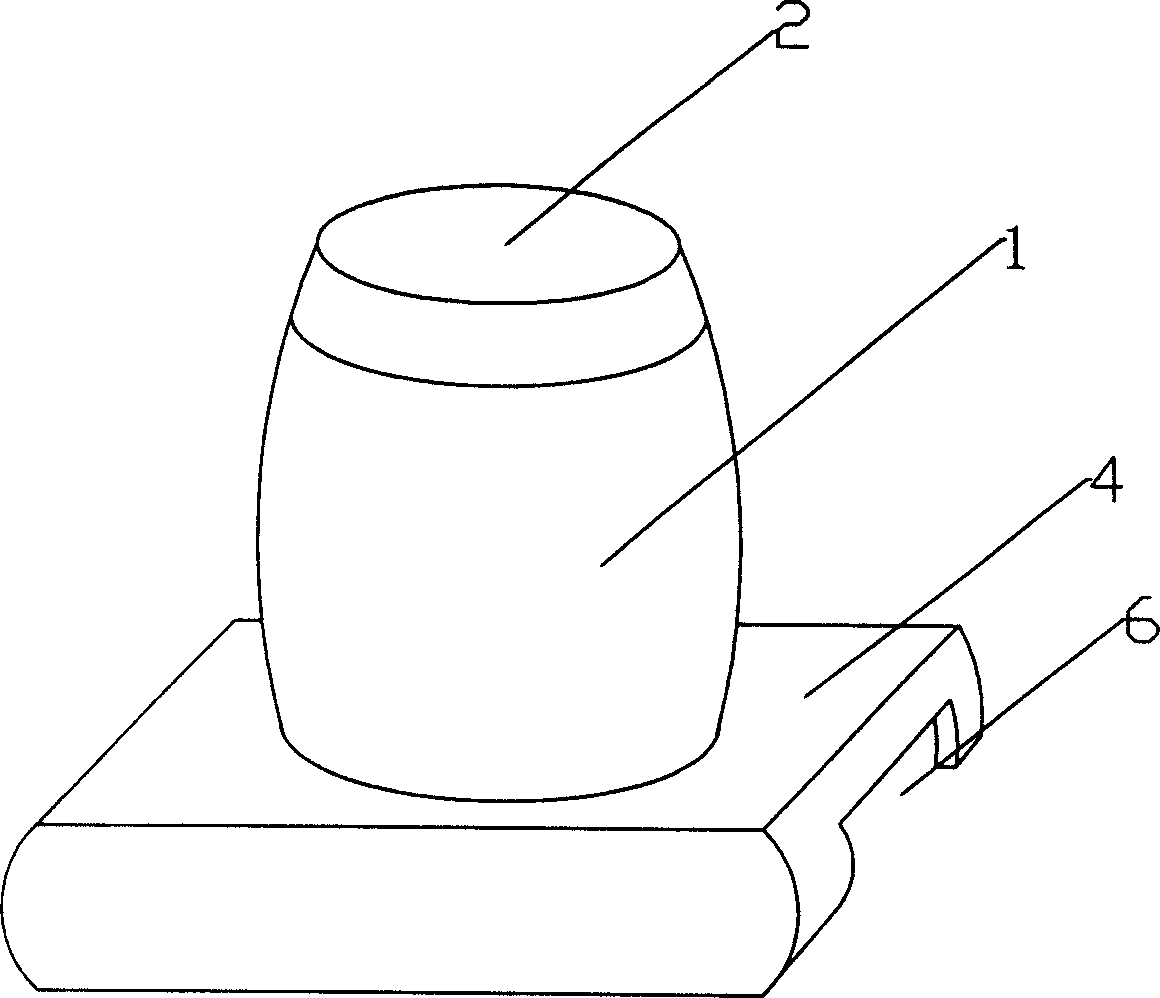

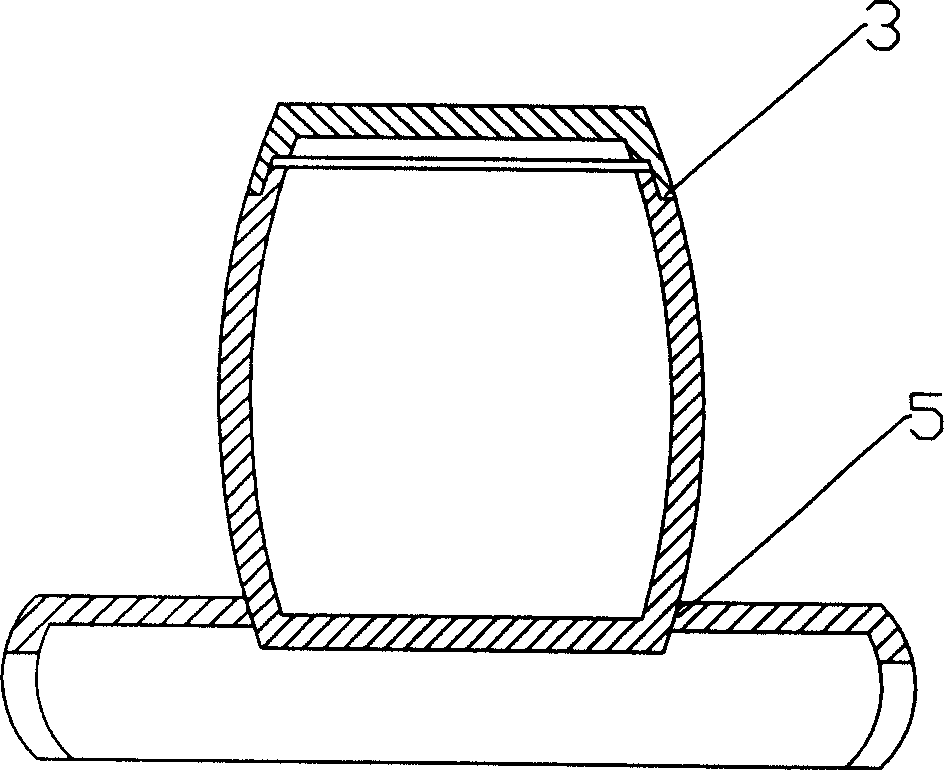

[0018] like figure 1 , figure 2 The described jade-like glass urn is mainly composed of an upper imitation jade glass urn and a lower wooden base 4 . The imitation jade glass is crystal clear and has more ornamental value. A cover body 2 is arranged on the upper part of the altar body 1, and a shoulder 3 is arranged on the altar body 1 at the junction with the cover body 2. After the ashes are loaded into the altar body 1, the altar body 1 and the cover body are placed at the shoulder 3. The body 2 fits together to completely isolate the ashes from the outside world, effectively protecting the ashes from being lost during storage. In order to make the columbarium be placed on the seat body 4 more stably, a seat ring 5 is arranged on the seat body 4 , and the bottom of the altar body 1 is embedded in the seat ring 5 . In order to be more convenient for the columbar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com