Inflammation diminishing capsule and its preparing process

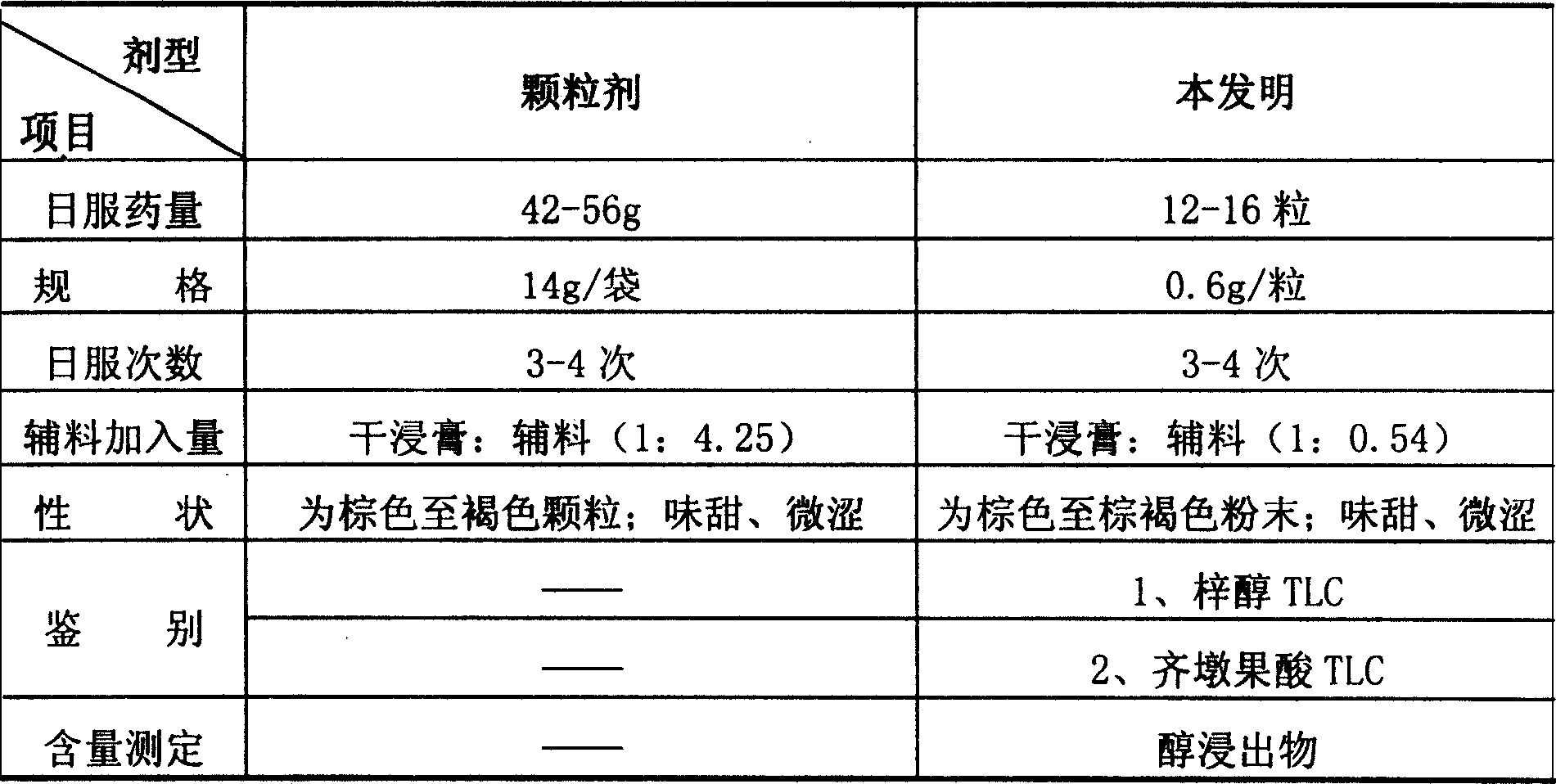

A technology of Yanning capsule and preparation process, which is applied in the field of Yanning capsule and its preparation, can solve problems such as lack of water addition, unfavorable product quality stability, etc., and achieve the effects of ensuring quality and clinical efficacy, saving auxiliary materials, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 3906.3g of velvet antler, 1953.1g of Hedyotis diffusa, 1953.1g of Commelina, the above three flavors, add water to decoct twice, add 12 times the amount of water for the first time, decoct for 1.5 hours, and add 10 times the amount of water for the second time , decocted for 1 hour, combined the decoction, filtered, and the filtrate was concentrated under reduced pressure (vacuum degree: 0.07-0.08Mpa) at a temperature of 60-65°C to a thick paste with a relative density of 1.10 (85-90°C). Ethanol makes the alcohol content to be 60%, stir well, let stand for 12 hours, filter, the filtrate is concentrated to a thick paste with a relative density of 1.32 (60-65°C), add 90g of micropowder silica gel, 100g of starch, mix well, and vacuum dry ( 60-70°C, vacuum degree is 0.07-0.08Mpa), take out the dry cream, the dry cream powder of the main drug is 390 grams, crushed into fine powder, then add 20 grams of starch to adjust the total amount to 600g, mix well, put Capsule si...

Embodiment 2

[0027] Other steps are the same as in Example 1, and the weight ratio of dry paste powder:starch:micronized silica gel is 400g:120g:80g.

Embodiment 3

[0029] Other steps are the same as in Example 1, and the weight ratio of dry paste powder:starch:micronized silica gel is 360g:80g:40g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com