Film stretching loading device under scanning microscopy environment and film distortion measurement method

A loading device and scanning microscope technology, applied in scanning probe microscopy, measuring devices, scanning probe technology, etc., can solve the problem of whether the calibration of the sample axis and the tensile axis cannot be determined, and the clamping and bonding are reliable Whether it is uncertain or not, the effective elongation is difficult to measure directly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

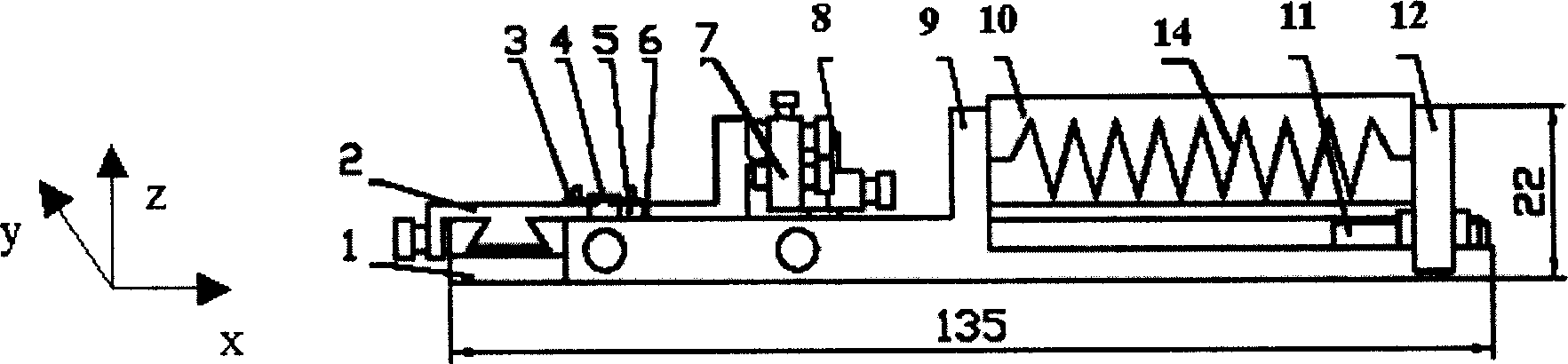

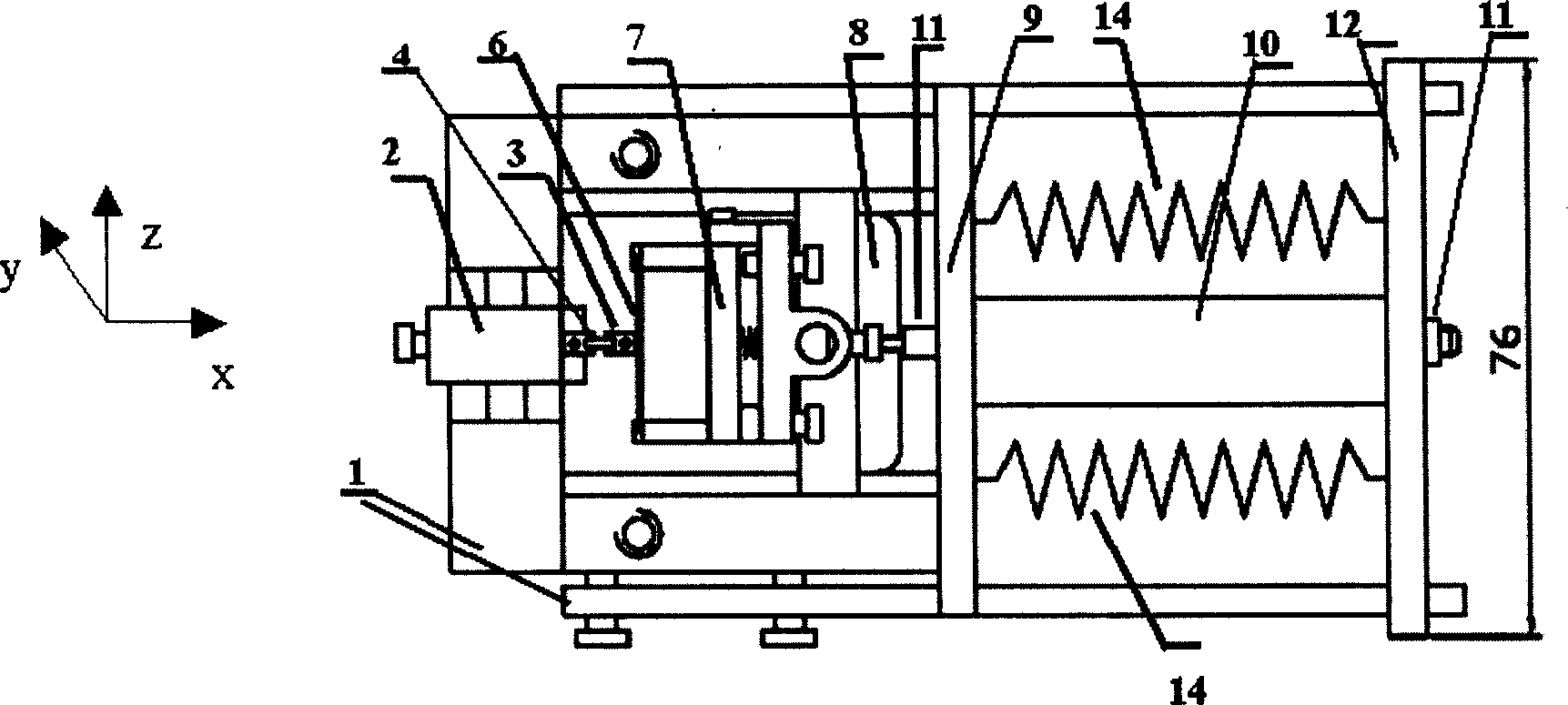

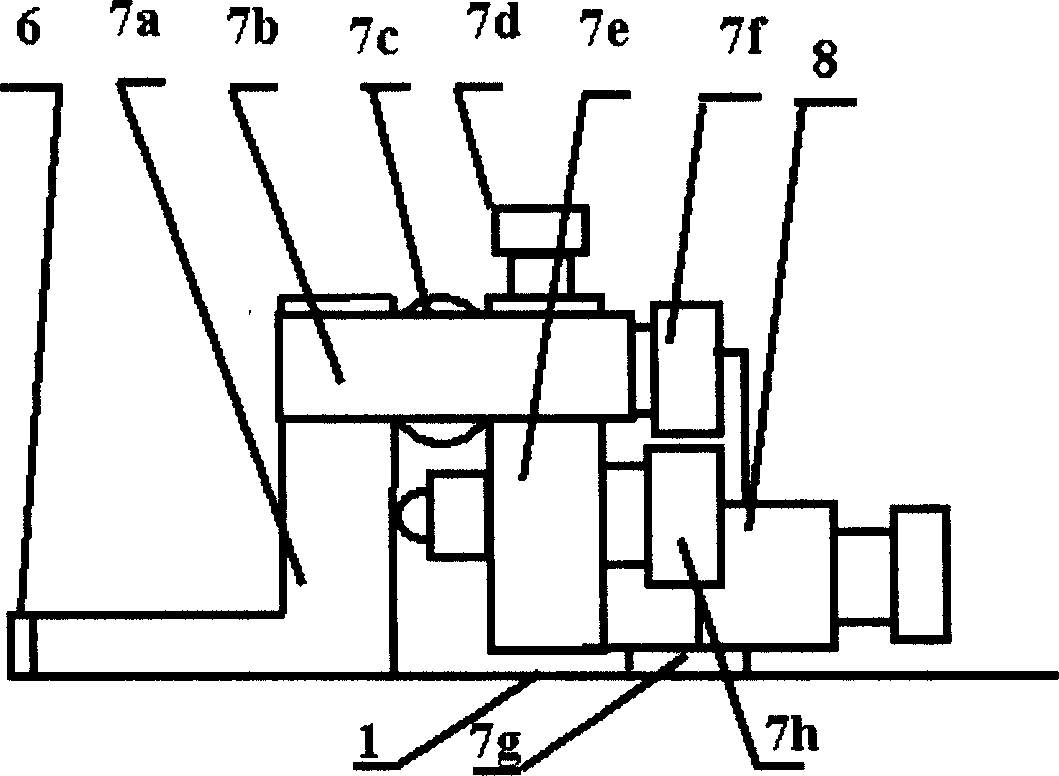

[0089] Embodiment: The thin film tensile loading device under the atomic force scanning microscope environment is used for the tensile deformation detection of the iron-nickel thin film and the thin film tensile loading device under the electron beam scanning microscope environment is used for the tensile deformation detection of the pure gold film

[0090] Apply the two kinds of film detection stretching and loading devices developed by the present invention to quantitatively detect the deformation field of the film in the whole field or in a local area. The parameter selection is as follows: for the thin film tensile loading device under the environment of the atomic force scanning microscope, the system is driven by a piezoelectric ceramic micro-displacement device, the voltage resolution is 0.1V, the corresponding displacement accuracy is 0.0245 μm, and the displacement range is 42.6 μm. The beryllium bronze used The size of the force-measuring elastic beam is 20mm×2mm×0.09...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com