Plasma display panel with coplanar electrodes having inclined discharge edges

A technology of plasma and coplanar electrodes, applied in the direction of AC plasma display panels, gas discharge electrodes, discharge tubes, etc., can solve the limitation of addressing speed and continuous frequency, increase the volume of pseudo-anode plasma region, and improve the luminous efficiency of plasma displays Low-level problems, to achieve the effect of limiting wear and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

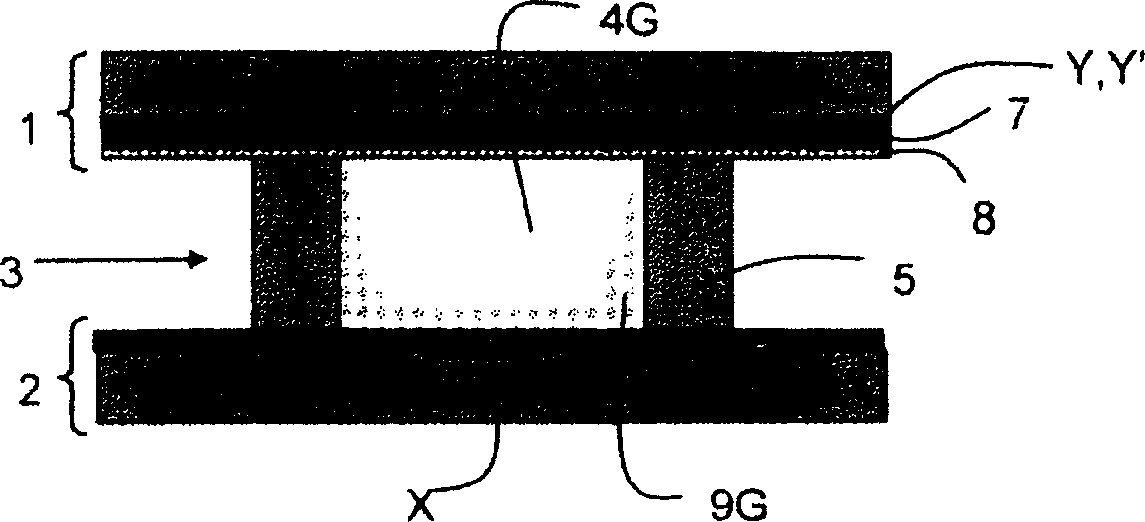

[0076] In order to simplify the description and illustrate the differences and advantages offered by the present invention compared to the prior art, the same reference signs are used for elements providing the same functions.

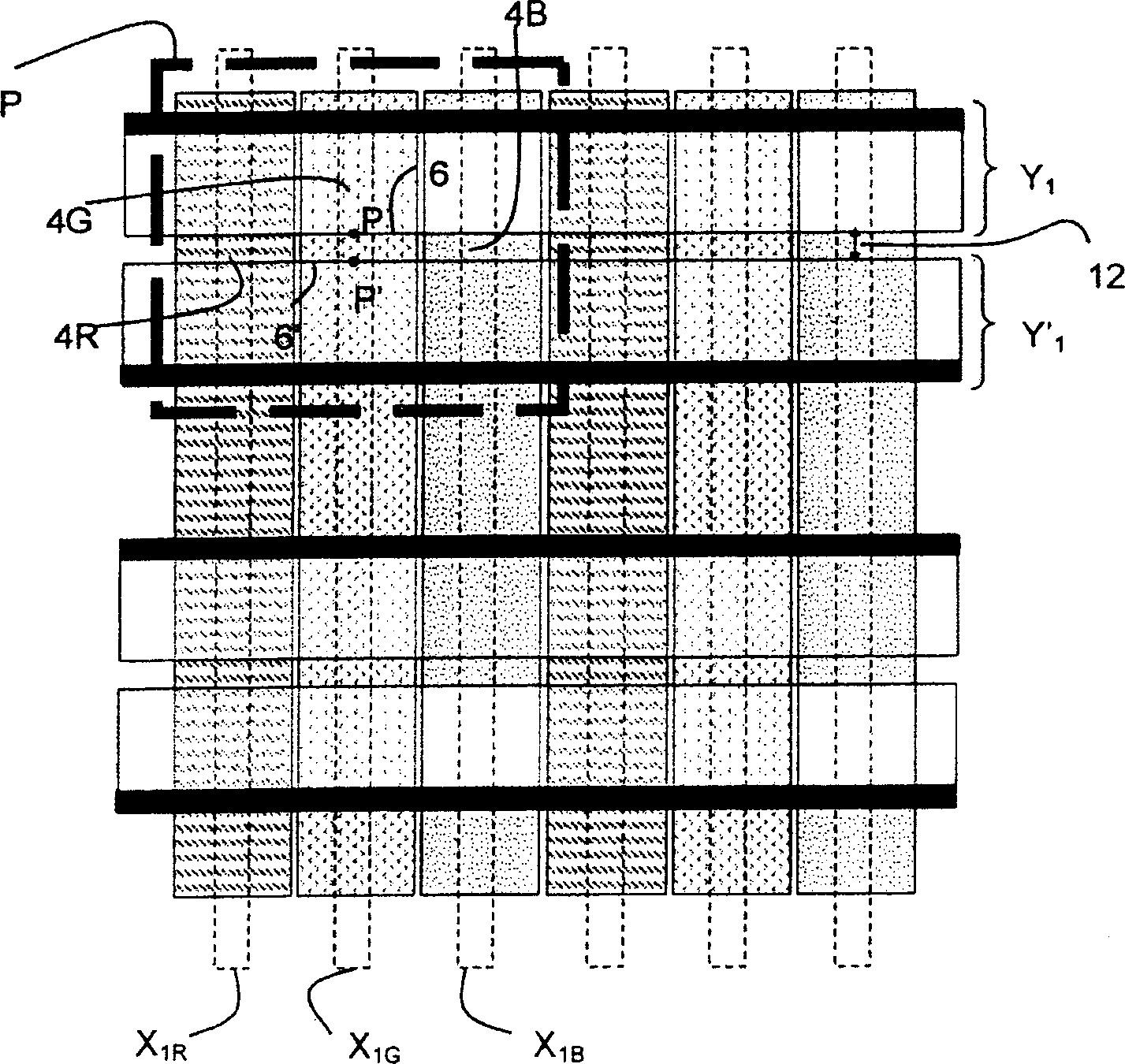

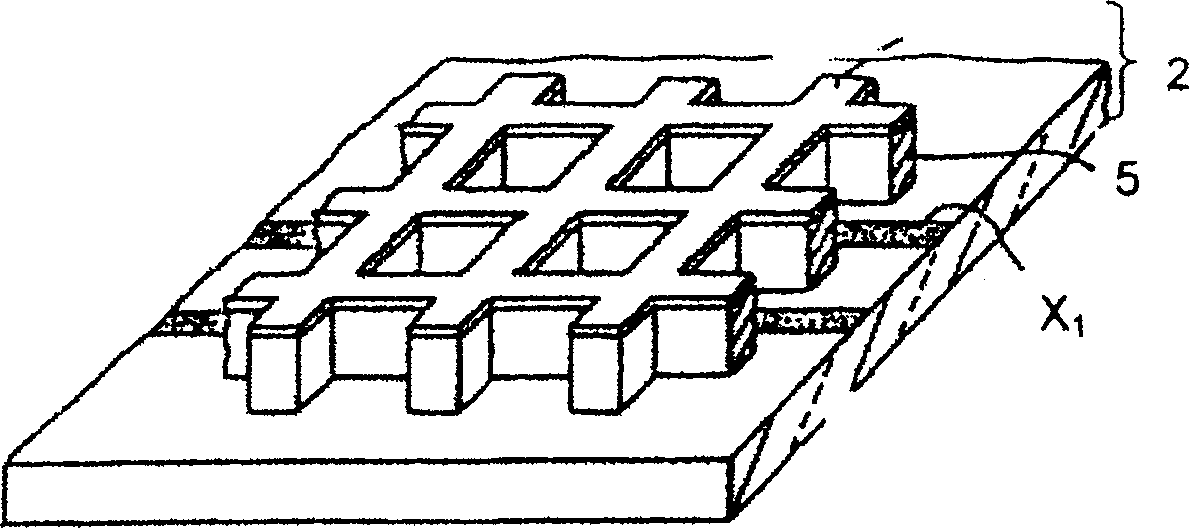

[0077] refer to Image 6 , the display according to the first embodiment of the present invention is similar to the previous reference Figure 1 to Figure 3 described display; therefore, in the remainder of the description, emphasis will be placed on differences from prior art displays; where elements are the same, reference should be made to the preceding displays; Dielectric layer of the surface electrodes; the display according to the invention comprises rectangular cells 4R, 4G, 4B arranged in a two-dimensional matrix and coplanar electrodes Y1, Y'1 across the display in a horizontal general direction.

[0078] Here each cell is bounded over its entire perimeter by rectilinear separator ribs 5, 5'; the vertical separator ribs 5 limit the size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com