Hot-blast furnace for casting mold and its baking method

A baking method and hot blast furnace technology, which are applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of unable to meet the requirements of pouring process, poor exhaust of casting sand molds and clay cores, and inability to dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

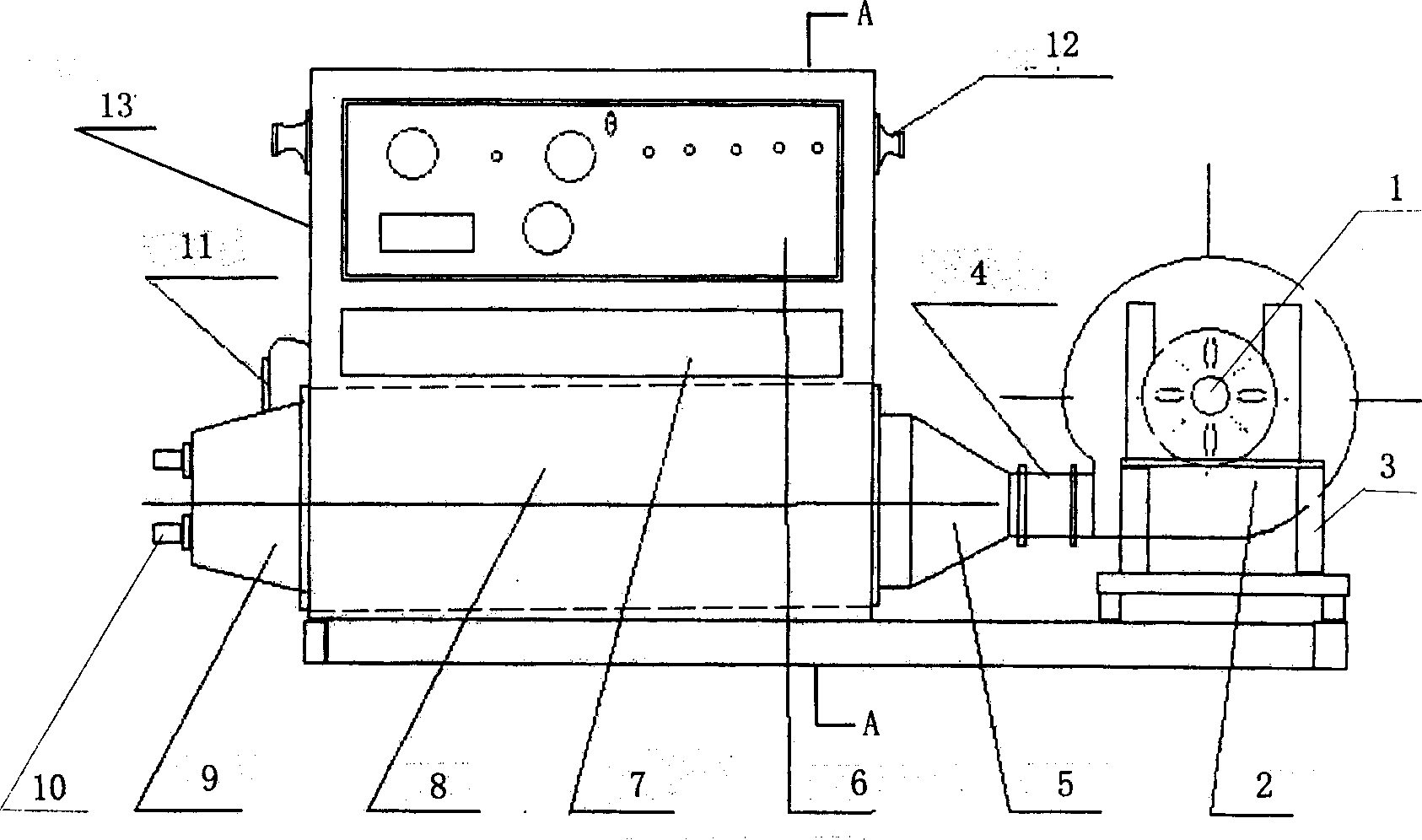

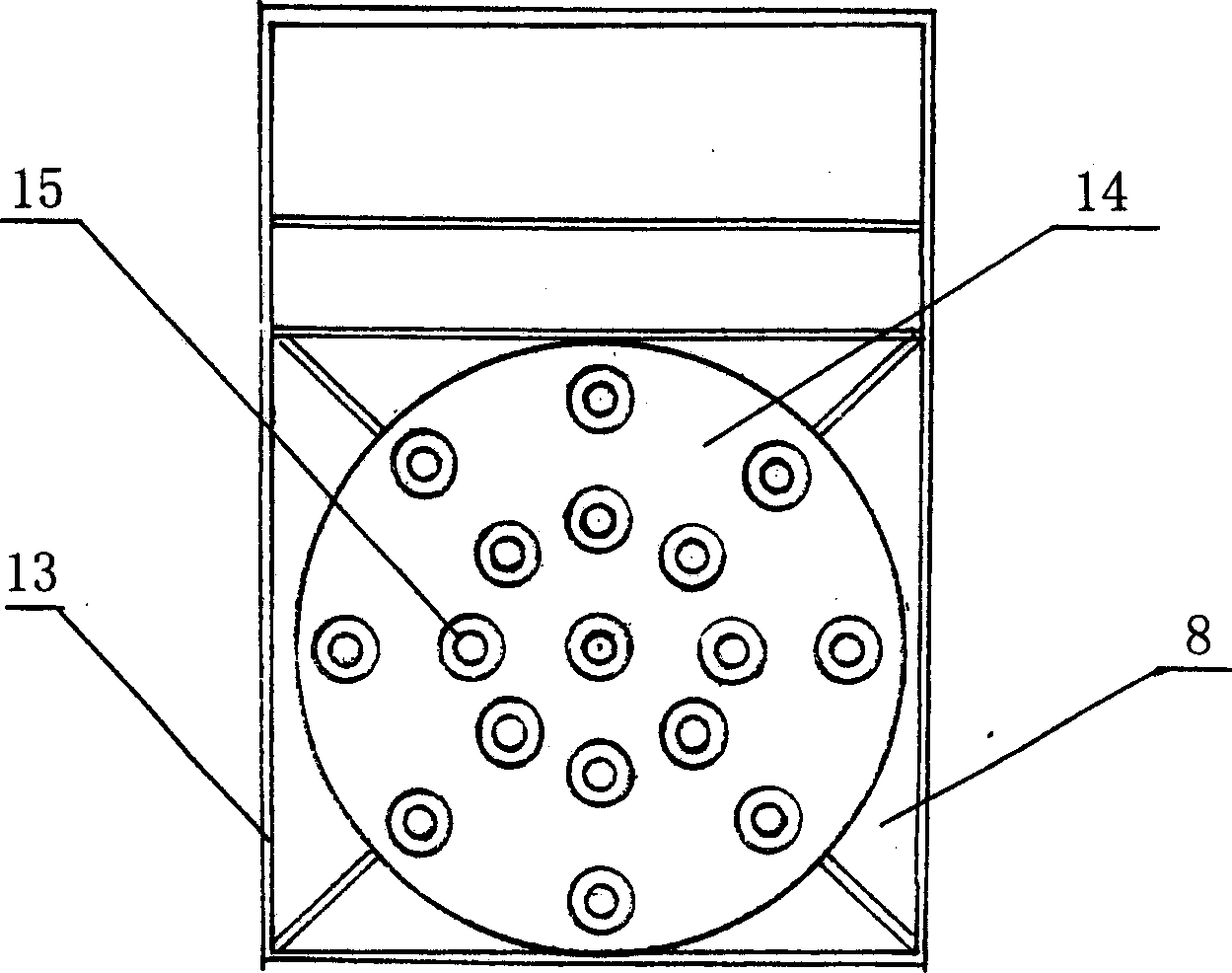

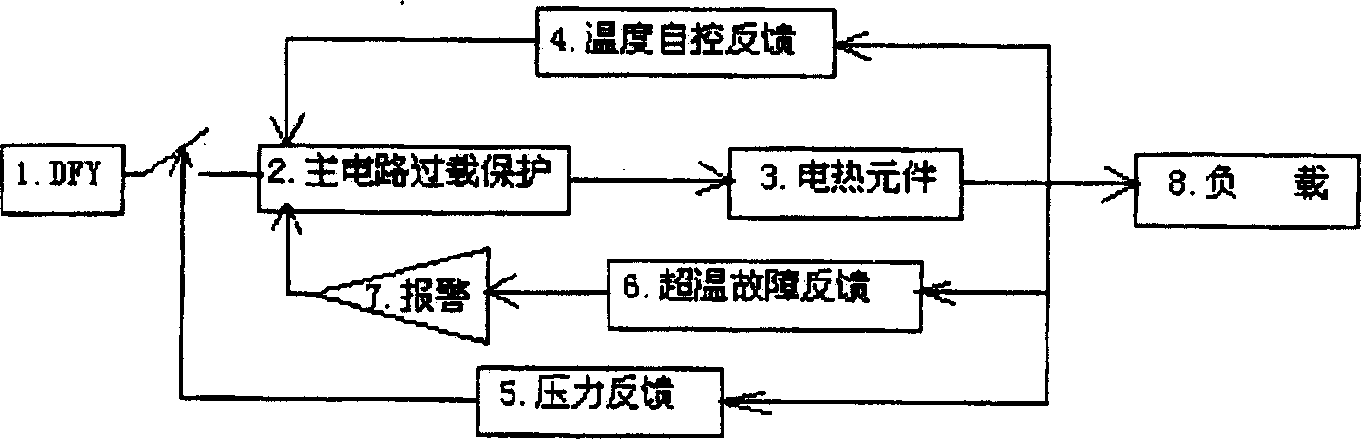

[0022] exist figure 1 , figure 2 Among them, the drive motor (1), fan (2) are installed on the fan base (3), the fan hose interface (4), air inlet (5), heating chamber (8), and air outlet (9), using screws Connection, the air outlet hose is connected to the flange (10), and the air outlet (9) is connected by welding, and the thermocouple (11) is screwed into the air outlet (9) with a screw thread to obtain the data of the output hot air temperature, and timely Feedback to the control instrument facilitates the electrical interlock control of the casting hot blast stove. The cooling window (7), the instrument operation panel (6) and the casing (13) are connected by hinges, and the lifting ring (12) and the casing (13) are welded. connection, it is convenient for hoisting and moving, and the overall on-site baking of large molds after boxing. The electrical appliances and thermocouples (11) installed on the instrument operation panel (8) and the honeycomb through-hole refracto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com