Methpd for separating and recovering Sb and Bi

A technology of separation and recovery and eluent, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of ineffective separation and recovery of Sb and Bi, the use of hydrogen sulfide gas, and the generation of arsenic gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (Sb neutralizes dross 2-step dry process)

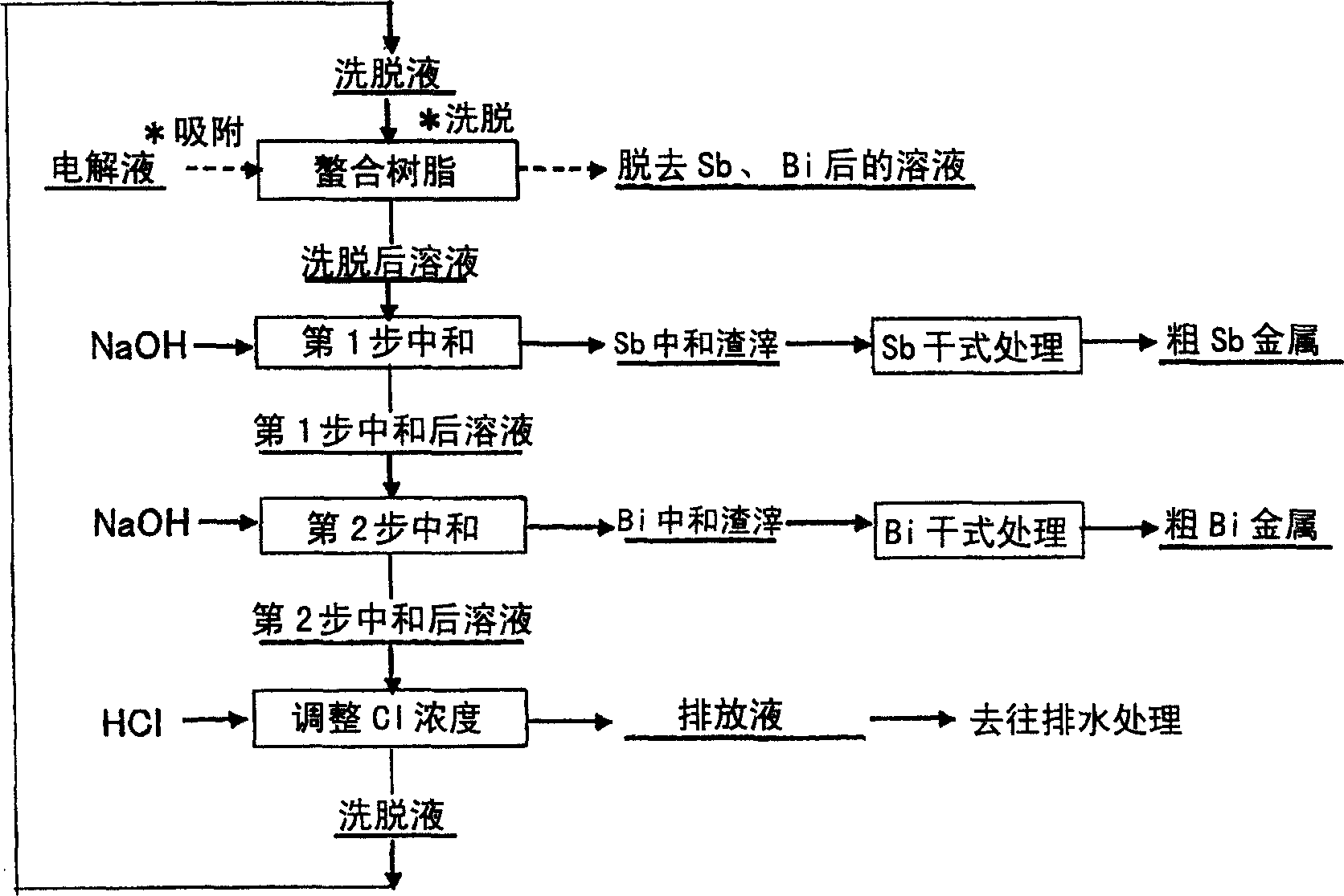

[0063] The chelating resin (Purolite S950) after adsorbing Sb and Bi was eluted with 6N hydrochloric acid solution, and an eluent having a composition as shown in Table 1 was recovered.

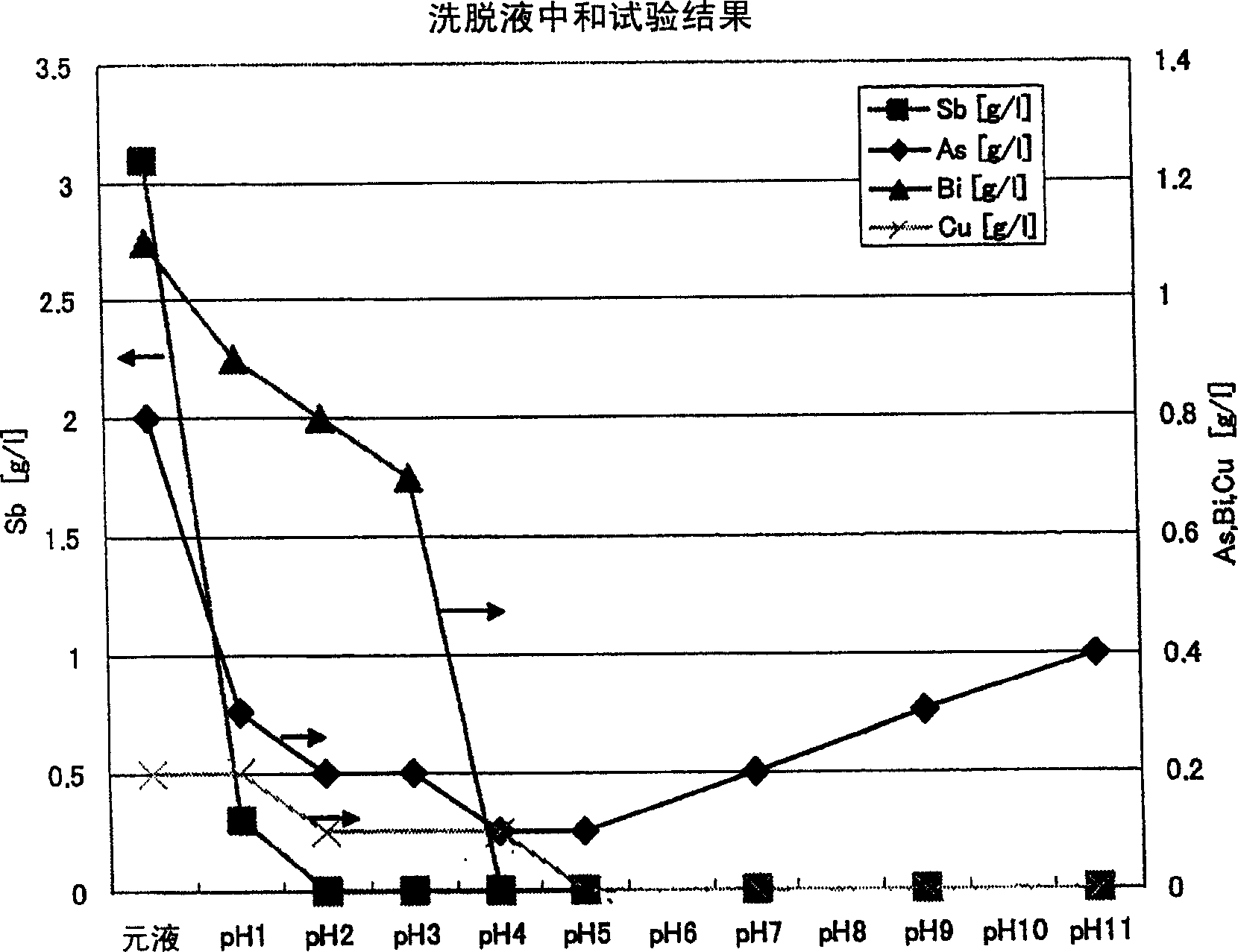

[0064] As

[0065] The above-mentioned eluate was neutralized to pH 2 with NaOH, followed by solid-liquid separation, and Sb neutralized residue was recovered.

[0066] Next, the neutralized filtrate having a pH of 2 was neutralized to pH 4 with NaOH, followed by solid-liquid separation, and Bi neutralized dross was recovered. Table 2 shows the composition of each neutralized residue. Concentrations up to 29.0 mass% Sb can be recovered from Sb neutralized dross. Concentrations up to 25.0 mass% Bi were recovered from Bi-neutralized slag.

[0067] As

[0068] Sb neutralizes dross to neutralize dross: Na 2 CO 3 : Charcoal powder = 10:2:1 ratio was mixed, dissolved at 900°C, and Sb metal (75.0mass% of Sb) was recovere...

Embodiment 2

[0072] (Sb neutralizes dross 1-step dry process)

[0073] In the 1-step dry process, in order to reduce the As in the recovered Sb metal, the solvent Na 2 CO 3 NaOH was used instead, and the ratio of neutralization residue: NaOH: carbon powder = 4:2:1 was mixed, dissolved at 950°C, and Sb metal (85mass% of Sb) with the composition shown in Table 4 below was recovered. In addition, since the treatment is performed at a high temperature of 950°C, when As is removed as an alkaline salt, Sb is also oxidized and volatilized, and the mobility of Sb to Sb metal is only 48%, which is extremely low. Although As can be removed, it is difficult to be used industrially because the recovery rate of Sb is poor as described above.

[0074] As

Sb

Bi

Cu

mass%

mass%

mass%

mass%

Sb metal

0.1

85.0

12.0

1.4

[0075] When reclaiming Sb metal, if the reduction melting of the neutralization dross and the operation of r...

Embodiment 3

[0078] (Bi neutralizes dross 2-step dry process)

[0079] With respect to the Bi neutralized dross, similarly to the Sb neutralized dross, a dissolution test may be carried out after recovering the metal by dry processing.

[0080] Set the blending ratio to Neutralize Dross: Na 2 CO 3 : carbon powder = 15:14:2, processed at a temperature of 900°C.

[0081] As shown in Table 5 below, Bi was 70.0 mass% in the recovered metal composition.

[0082] As

Sb

Bi

Cu

mass%

mass%

mass%

mass%

Bi metal

14.0

0.33

70.0

14.0

[0083] Then, in order to remove As from the recovered Bi metal, the recovered metal was subjected to alkali treatment at 750° C. (mixed with NaOH and redissolved).

[0084] As shown in Table 6 below, the metal composition after alkali treatment was 80.0 mass%.

[0085] As

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com