Robot

A robot and motor technology, applied in the field of robots, can solve the problems of low limit stroke speed, shortened life of parts, and heavy weight, and achieve the effect of suppressing the increase of current consumption, avoiding large-scale and extending the stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The configuration of the present invention will be described in detail below based on the embodiments shown in the drawings.

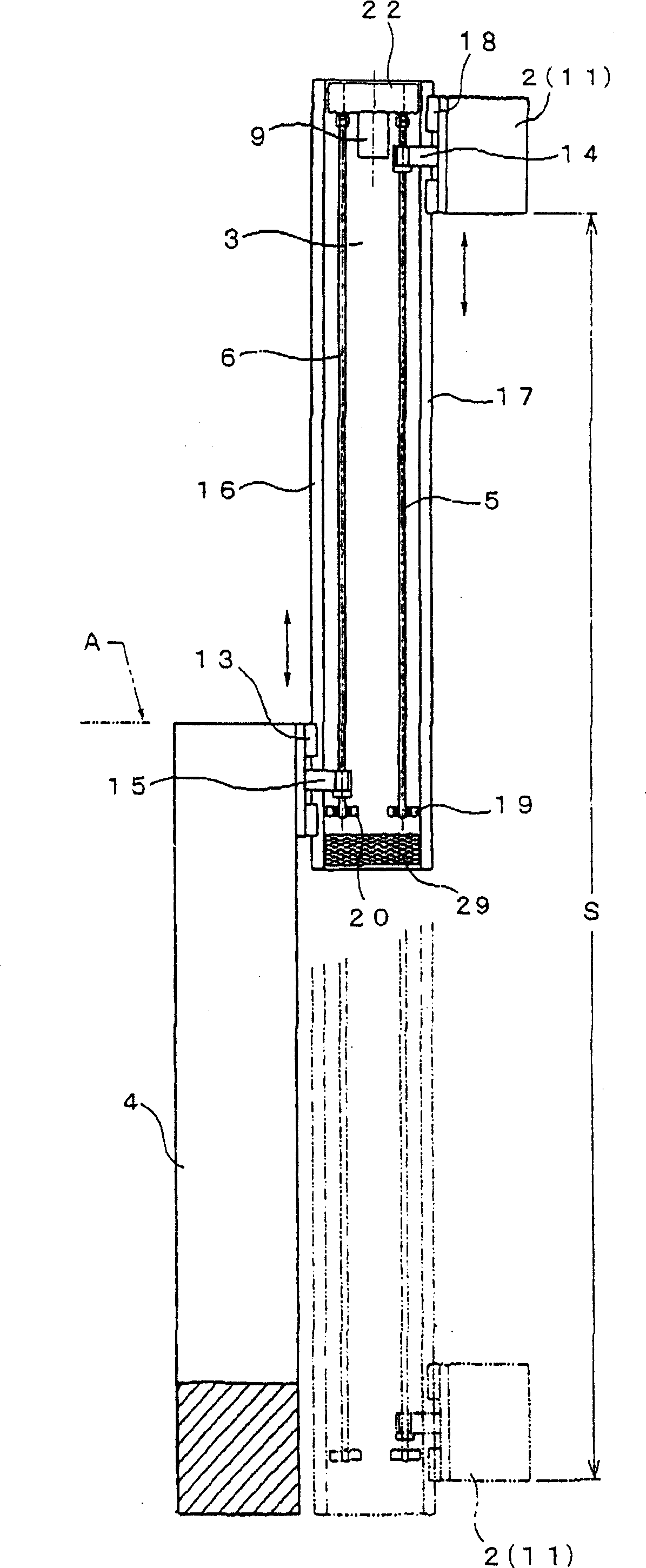

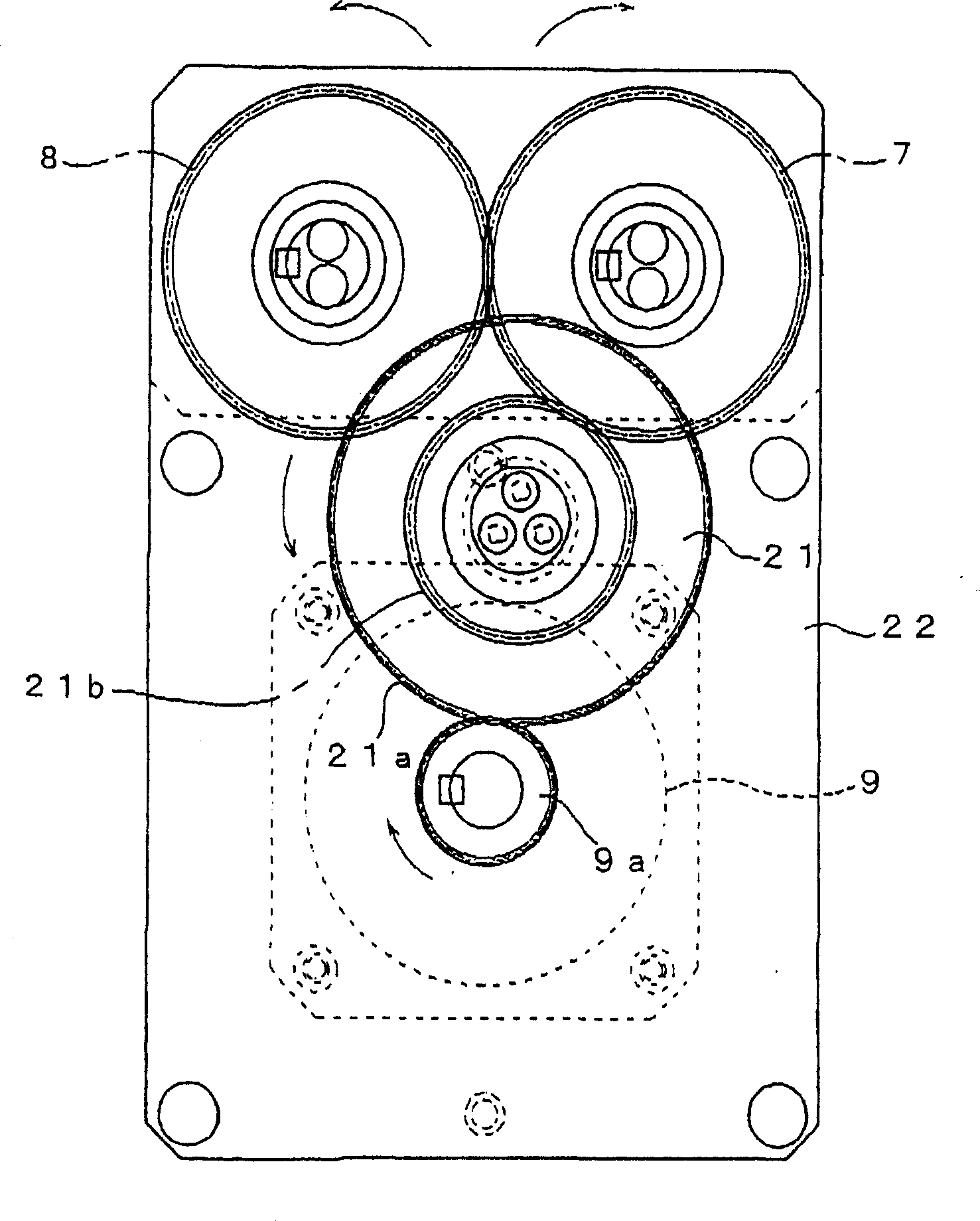

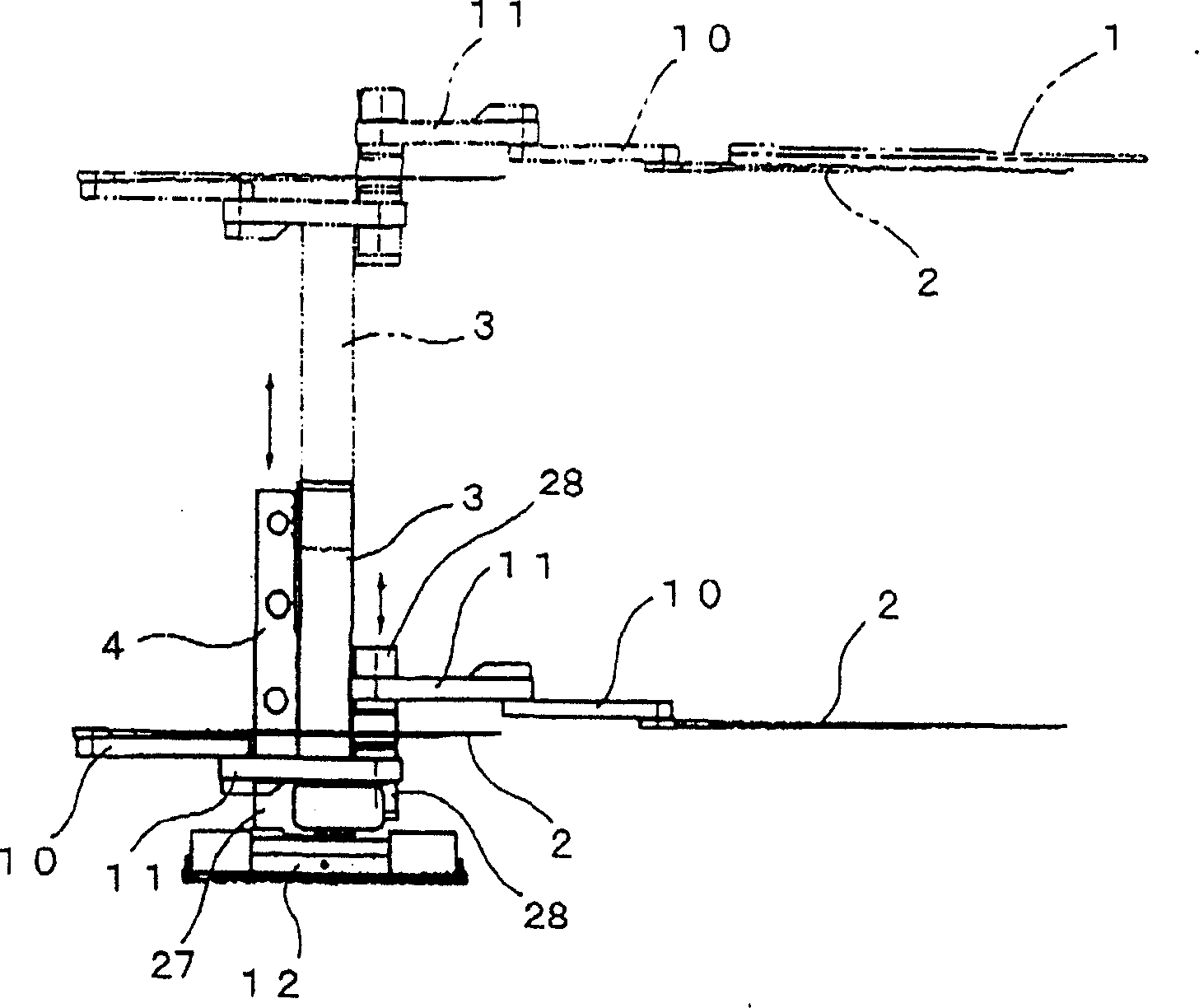

[0030] Figure 1 ~ Figure 3 An example of the present invention is shown. The robot of the present invention has the hand 2 that holds the workpiece 1, and the robot of the present embodiment includes a first frame 3 that supports the hand 2 that can move up and down and a second frame 4 that supports the first frame 3 that can move up and down. Inside the first frame 3, a first ball screw 5 for moving the hand 2 up and down and a second ball screw 6 for moving the first frame 3 up and down relative to the second frame 4 are arranged side by side in the vertical direction. The motor 9 is directly or indirectly connected to the first gear 7 that rotates integrally with the first ball screw 5 and the second gear 8 that rotates integrally with the second ball screw 6 .

[0031] More specifically, in this embodiment, the motor 9 and the gear train...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap