Sensing device for optical fiber optical grating flow speed

A fiber grating and sensing device technology, applied in the direction of measuring fluid velocity by pressure difference, detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

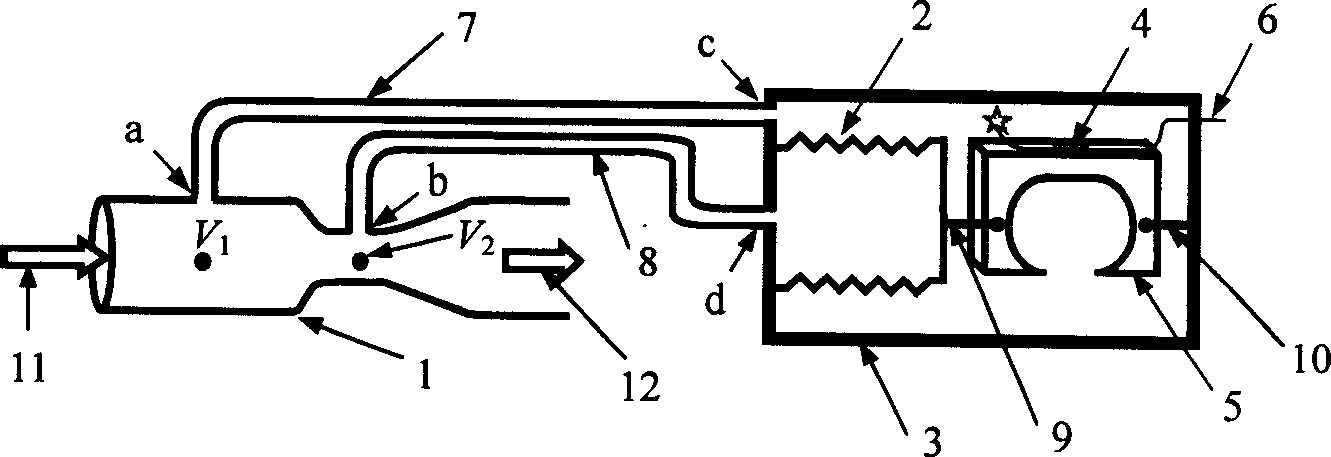

[0035] The velocity-pressure tube is made of glass.

[0036] The airtight telescopic tube is made of aluminum foil tube.

[0037] The airtight cylinder and the split ring are made of plexiglass (Young's modulus is about 2500Mpa).

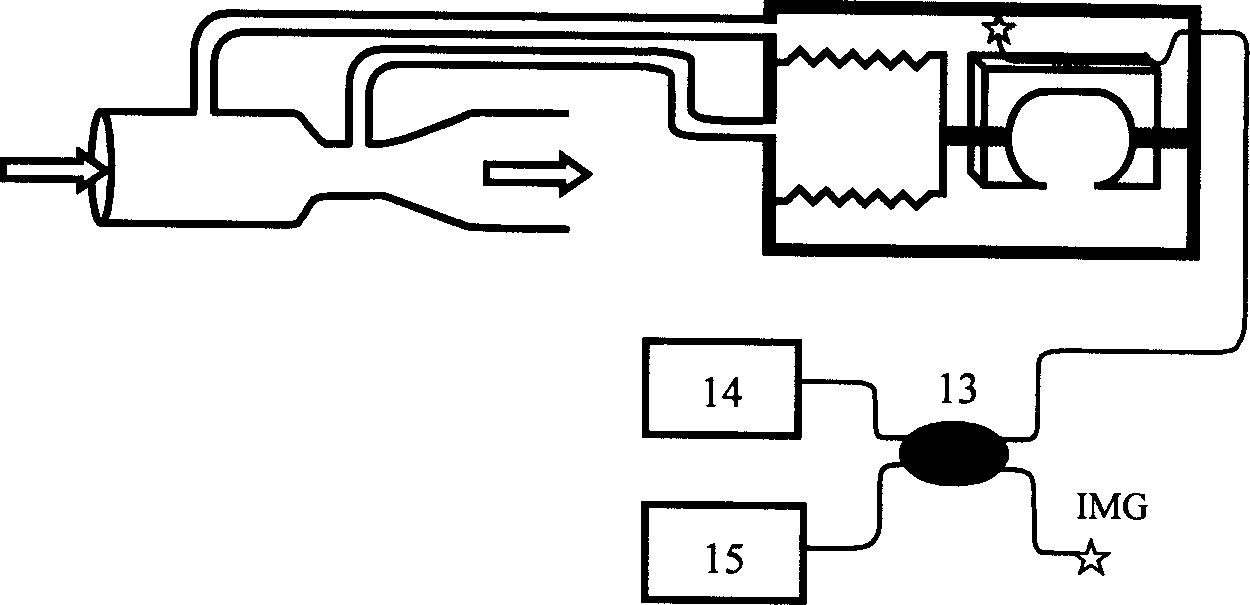

[0038] Fiber Bragg grating is a fiber Bragg grating written by using quartz single-mode fiber, using ultraviolet exposure technology and phase mask method, or a long-period fiber grating written by using amplitude mask method. The fiber grating is pasted on the side of the split ring straight beam. The fiber is a quartz single-mode fiber; the fiber coupler is a 2×2 or 1×2 fiber coupler.

[0039] The light source is a broadband light source or a tunable fiber laser; the optical detector is a fiber optic spectrometer.

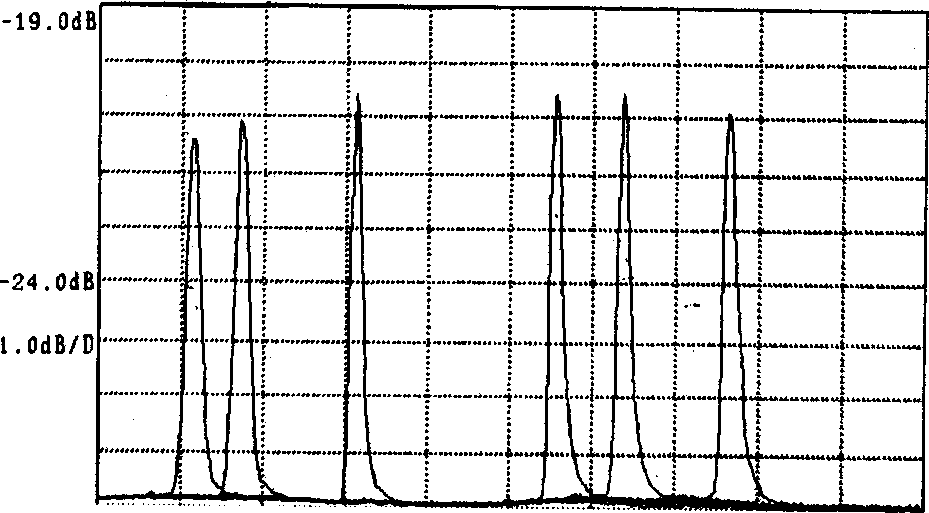

[0040] The actually manufactured flow rate-pressure tube has an inner diameter of 26.5mm and a throat inner diameter of 11.0mm. The effective cross-sectional area of the telescopic tube S=9.5×10 -3 m2 , the fiber Bragg grating u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com