Cell microinjection instrument

A technique of injecting instruments and cells, applied in the fields of biochemical instruments, enzymology/microbiology devices, biochemical equipment and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

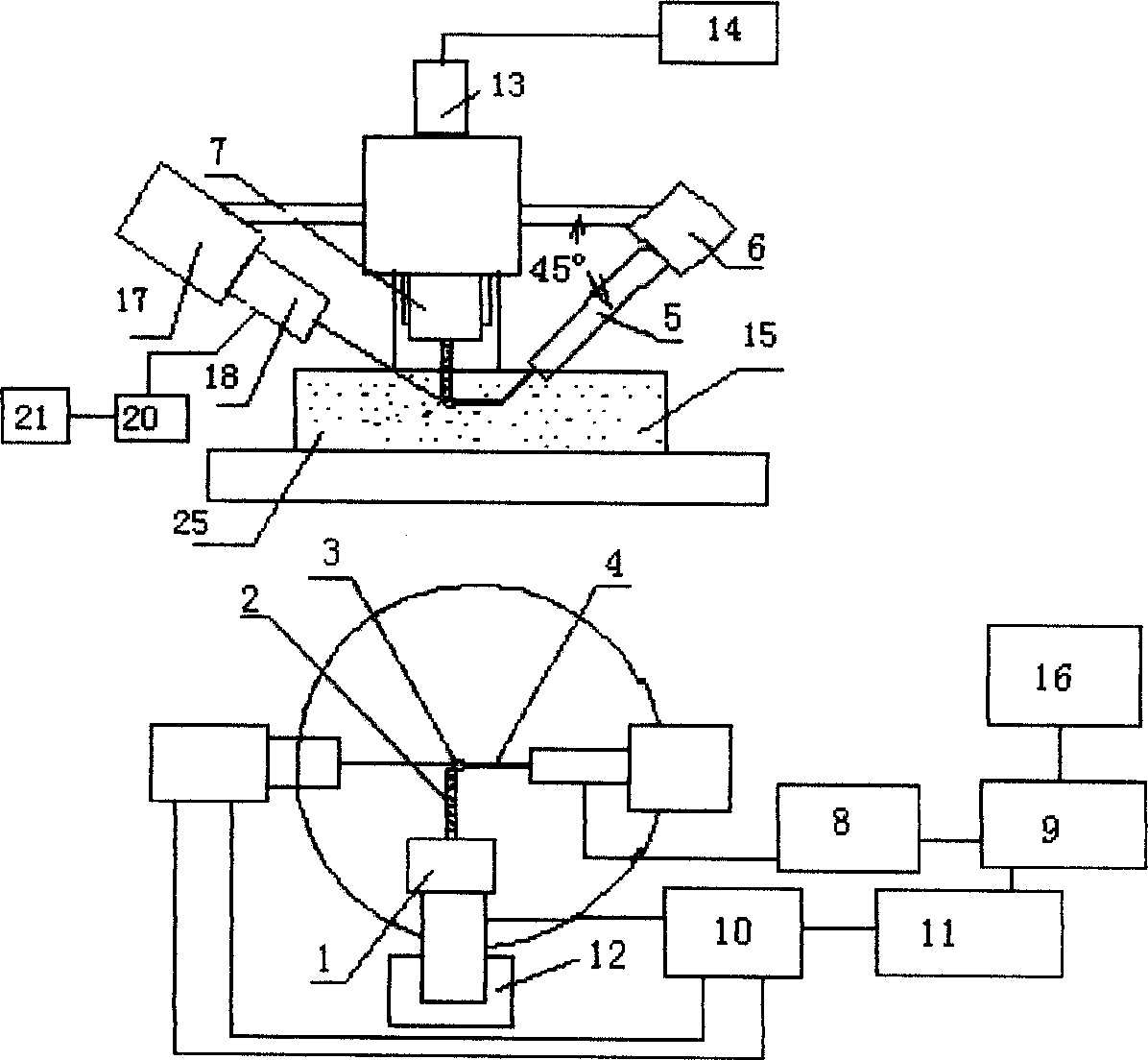

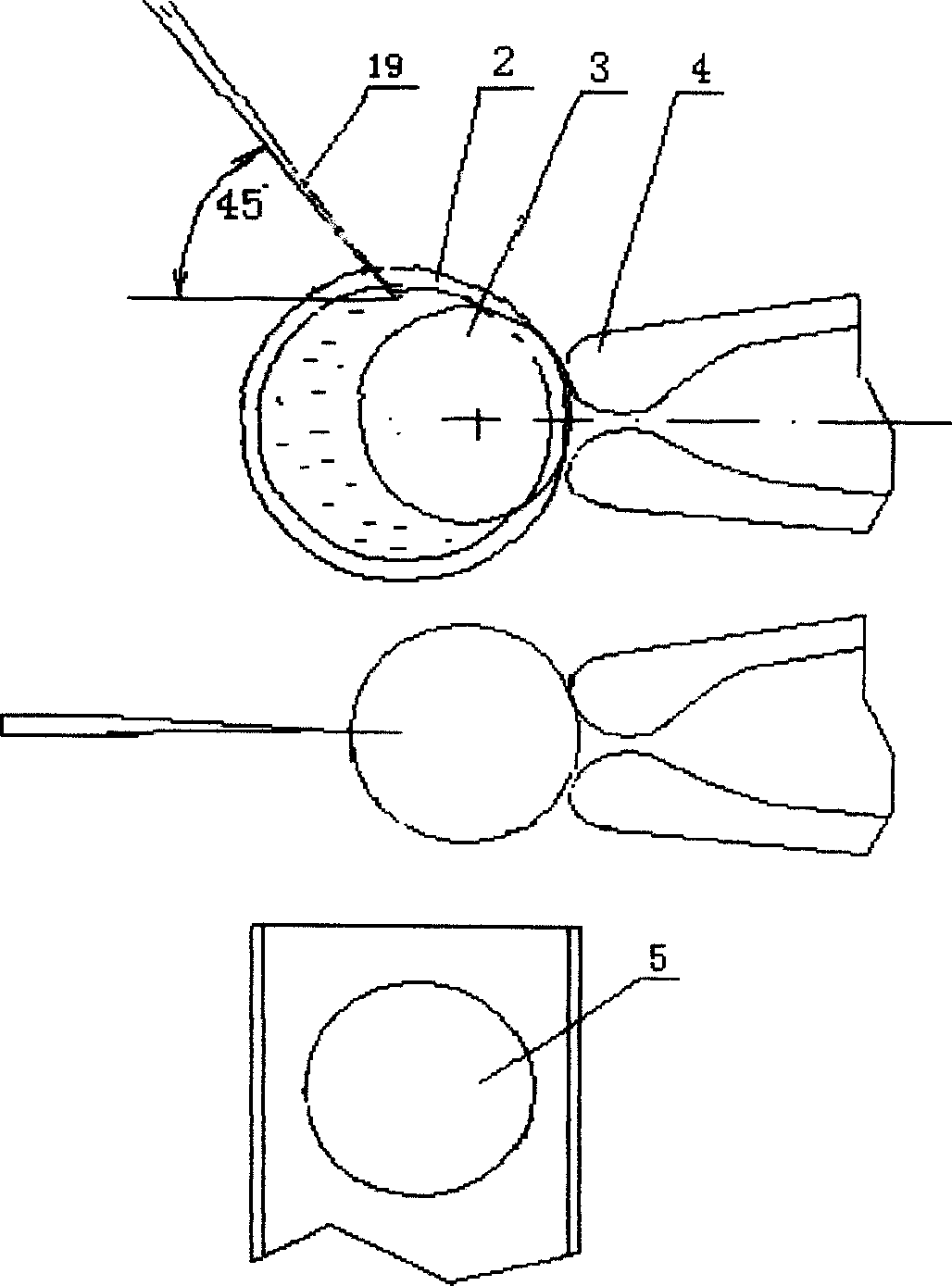

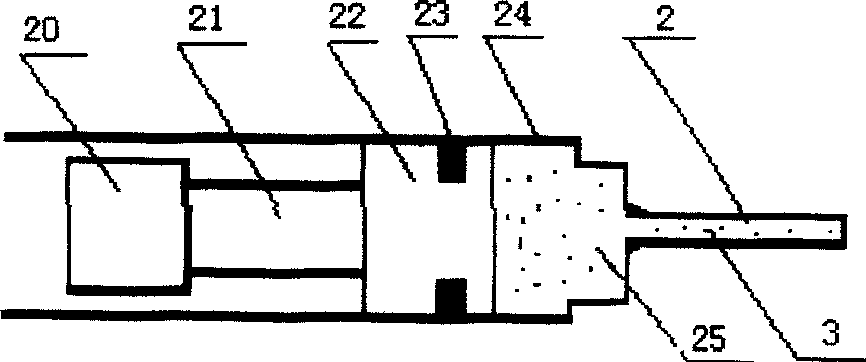

[0009] look first figure 1 , the experimental device consists of a cell transporter 1 and a transport micropipe 2 to form a cell transporter, a suction needle 4, a pressure device capable of generating positive and negative pressure, a suction device 5, and a cell syringe 18 for injecting medicinal liquid. A pressure sensor is installed in the 5, and the pressure sensor is connected with the computer 11 controlling the cell transporter through a control circuit. The micro-channel 2 is bent by 165° and installed on the cell transporter 1, and the cell transporter 1 is installed on the three-dimensional adjuster 12 capable of adjusting the three-dimensional direction. The holding needle 4 is bent at 135°, the cell holder 5 is installed on the right trimmer 6 with a 5-dimensional adjustment function at 45° to the horizontal plane, the three-dimensional adjuster 12 and the left trimmer 6 are all installed on the inverted microscope 7 on the stand. A cell injector 18 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com