System for monitoring the quality of industrial processes and method therefrom

A process quality, industrial process technology, used in the field of systems monitoring industrial processes, can solve the problems of magnetic interference and expensive power cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

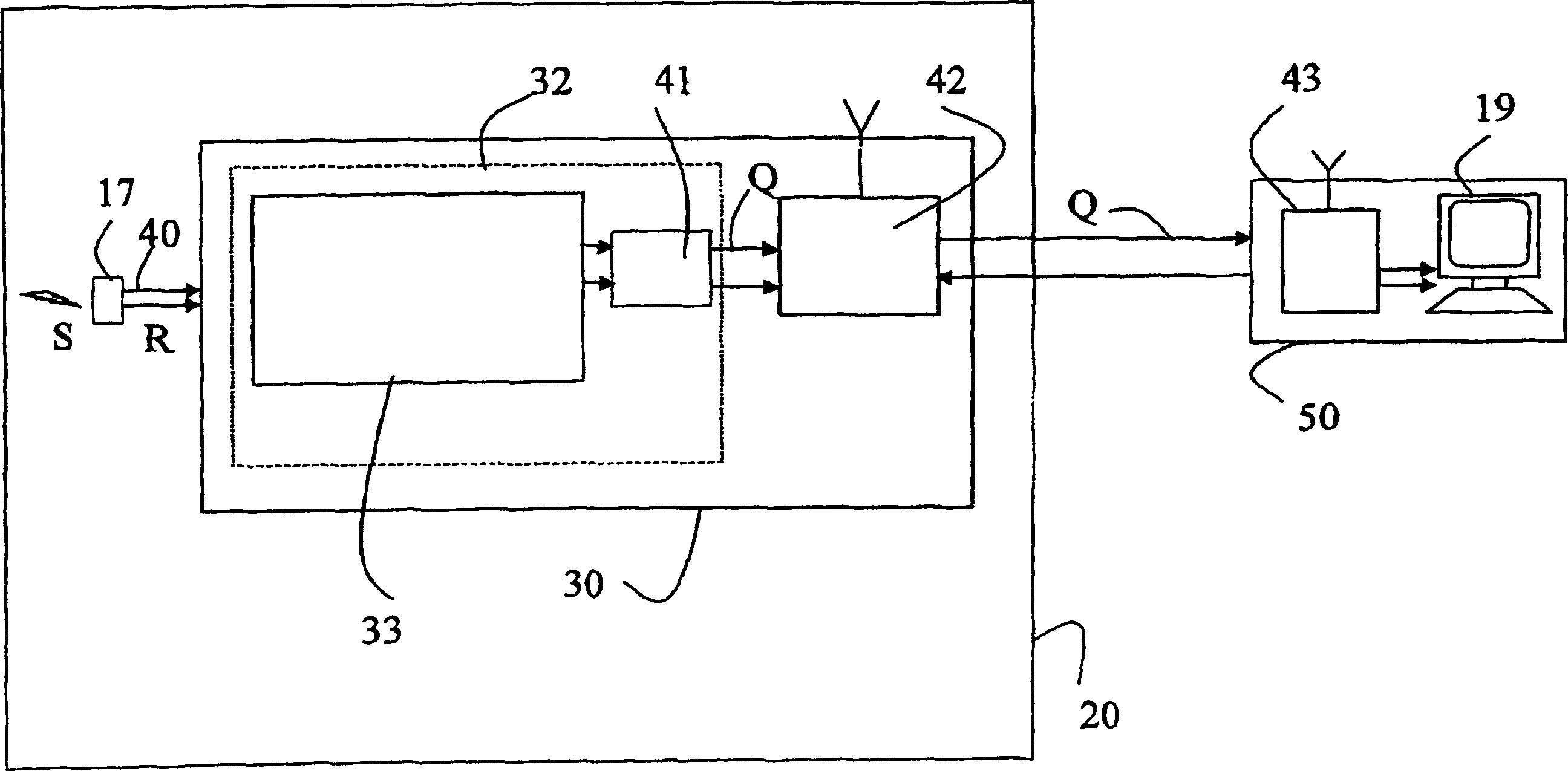

[0019] Briefly, according to the proposed system, a smart unit is placed locally in the workstation, said smart unit is configured to capture signals from sensors and obtain quality signals with lower frequency band requirements, which are transmitted wirelessly to processors that monitor these processes and perform, for example, waste management processes.

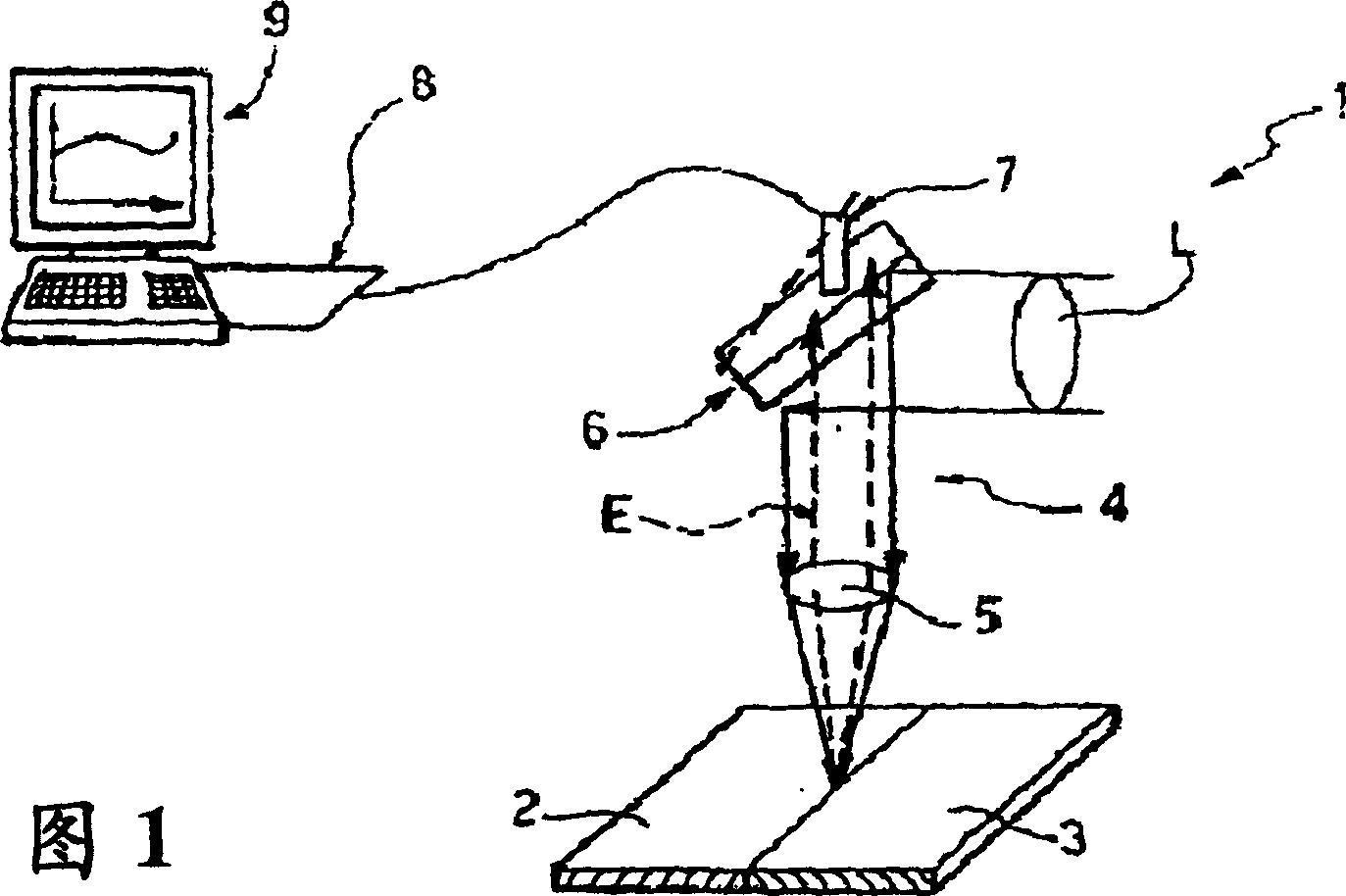

[0020] image 3 Shows a block diagram of a system for monitoring an industrial process according to the present invention, wherein reference numeral 17 refers to a sensor, which is arranged in a workstation 20 such as a CO 2 Inside the focusing head of the laser, or if the laser is a neodymium-YAG type, inside the cavity. Said sensor 17 is therefore arranged near the workstation 20, which captures the radiation from the laser welding process and generates an analog voltage signal R, in particular an analog voltage signal of 0 to 0.5 volts.

[0021] The analog voltage signal R is transferred to a capture and processing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com