High quality single crystal and method of growing the same

A technology for growing single crystals and single crystals, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., and can solve the problems of not being able to obtain high-quality single crystals and not fully ensuring the productivity of high-quality single crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

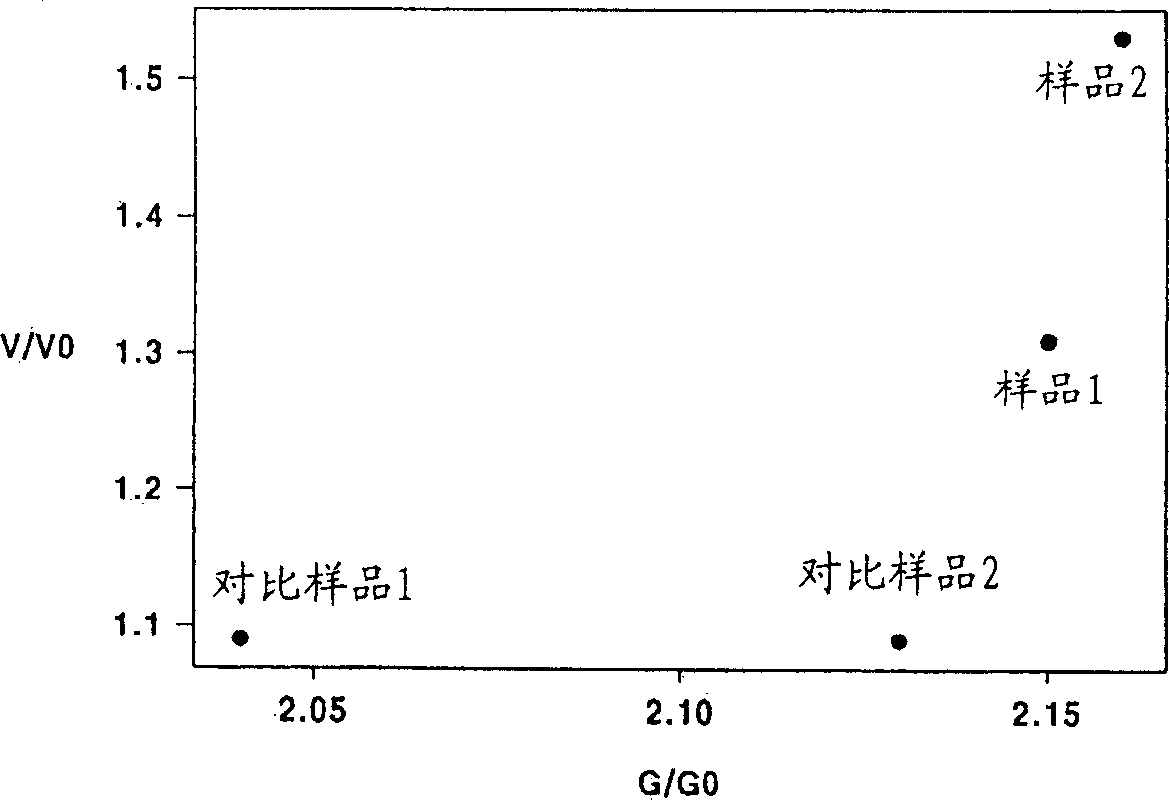

Examples

Embodiment Construction

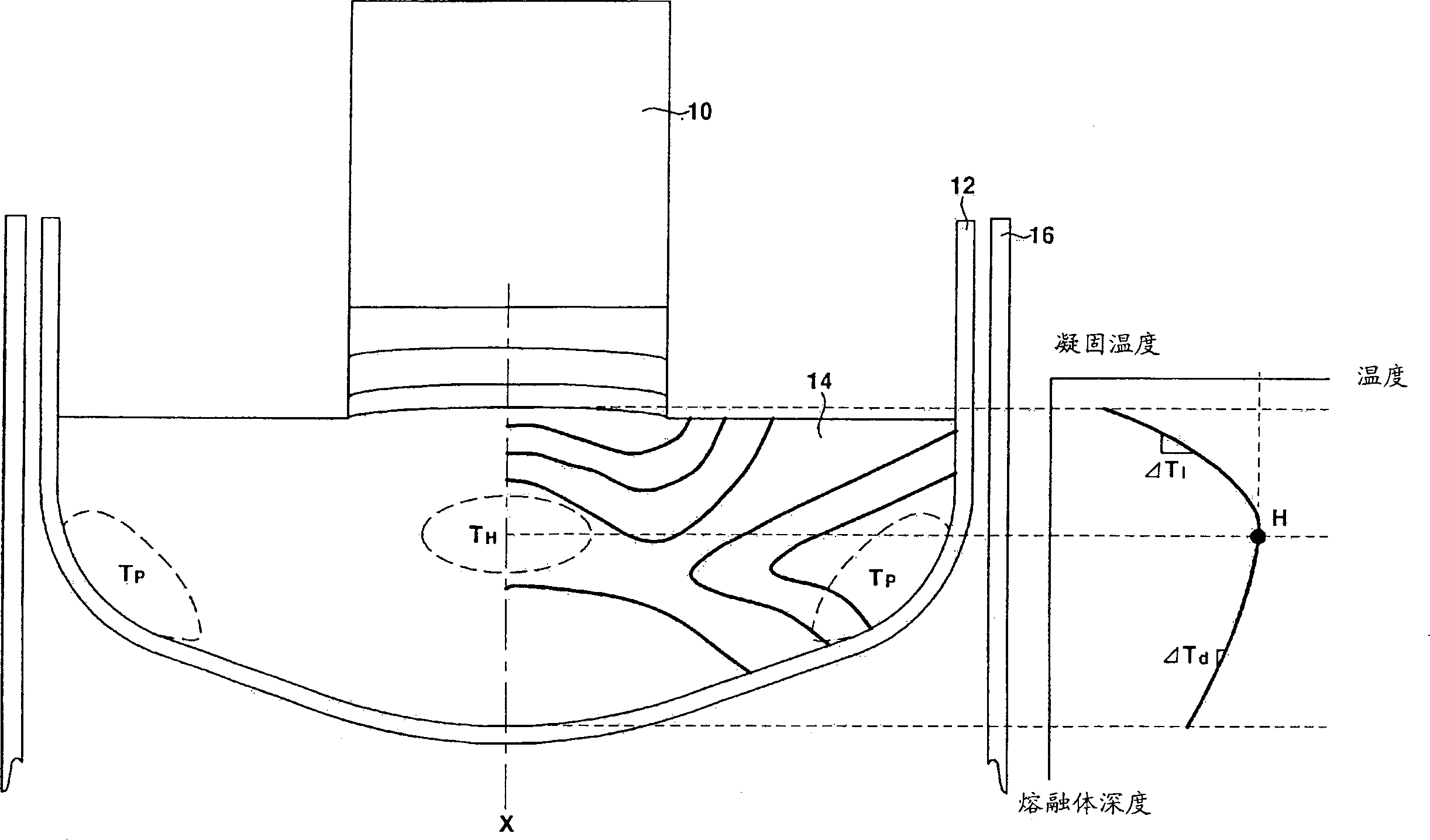

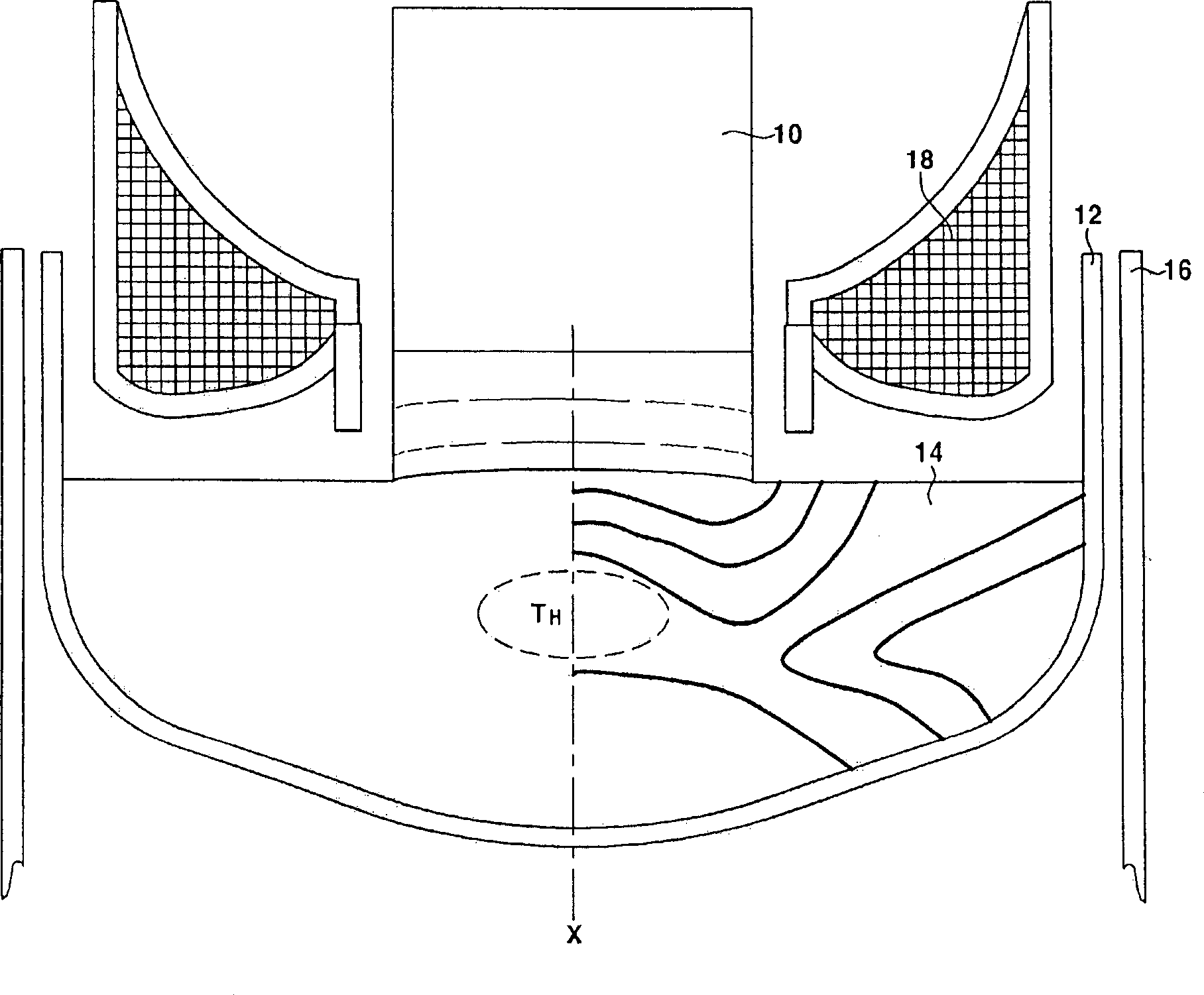

[0020] The present invention is based on the fact that in addition to controlling the temperature gradient of the solid phase single crystal and the morphology of the solid-liquid interface, there is also a more critical factor that is conducive to the significant reduction of point defects in the growth of high-quality single crystals. . According to the present invention, in order to overcome the deficiencies of the solid phase reaction, such as the diffusion of point defects after crystallization, the fluid state of the liquid phase immediately before solidification is thoroughly analyzed, and it is found for the first time that the temperature distribution of the melt is the most important One of the factors.

[0021] Generally, the mechanism of crystal growth includes growth units, such as atoms or molecules moving toward the crystal growth interface or metastable region and then attaching to it. In this case, the driving force for the growth unit to move toward the crystal g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com