Plant and active water composite flame retardant extinguishing agent

A technology of fire extinguishing agent and active agent, applied in the field of plant active flame retardant fire extinguishing agent, can solve the problems of pollution damage, good effect, poor effect, etc., and achieve the effect of strong fire extinguishing function, huge power, and good conjunctival sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

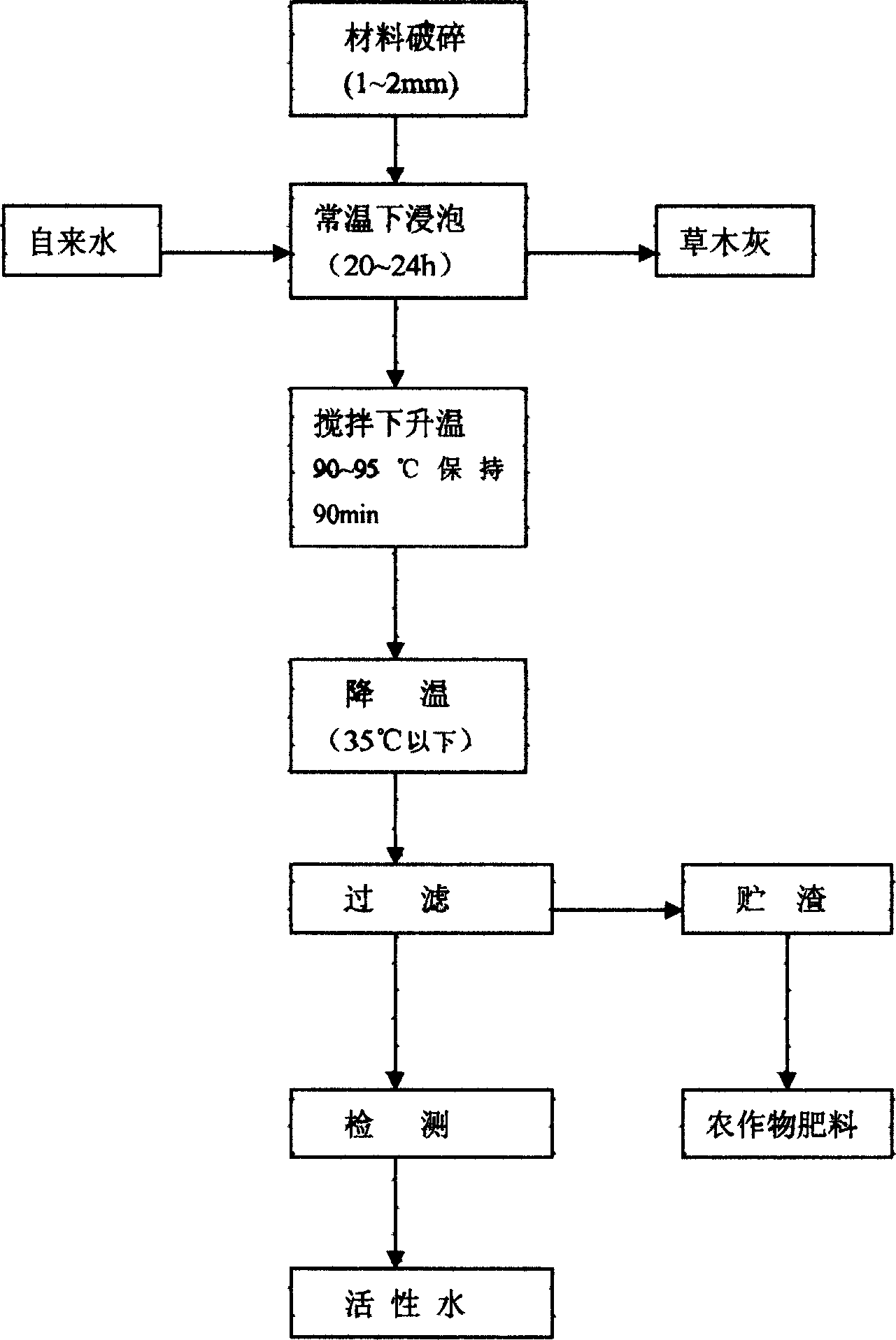

[0041] Take 12 parts of miscellaneous grain distiller's grains, 5 parts of weed wood ash, add 93 parts of water, soak at room temperature for 20 hours, raise the temperature to 90°C and keep it for 90 minutes, cool down to below 35°C, filter and take the clear liquid to obtain active water.

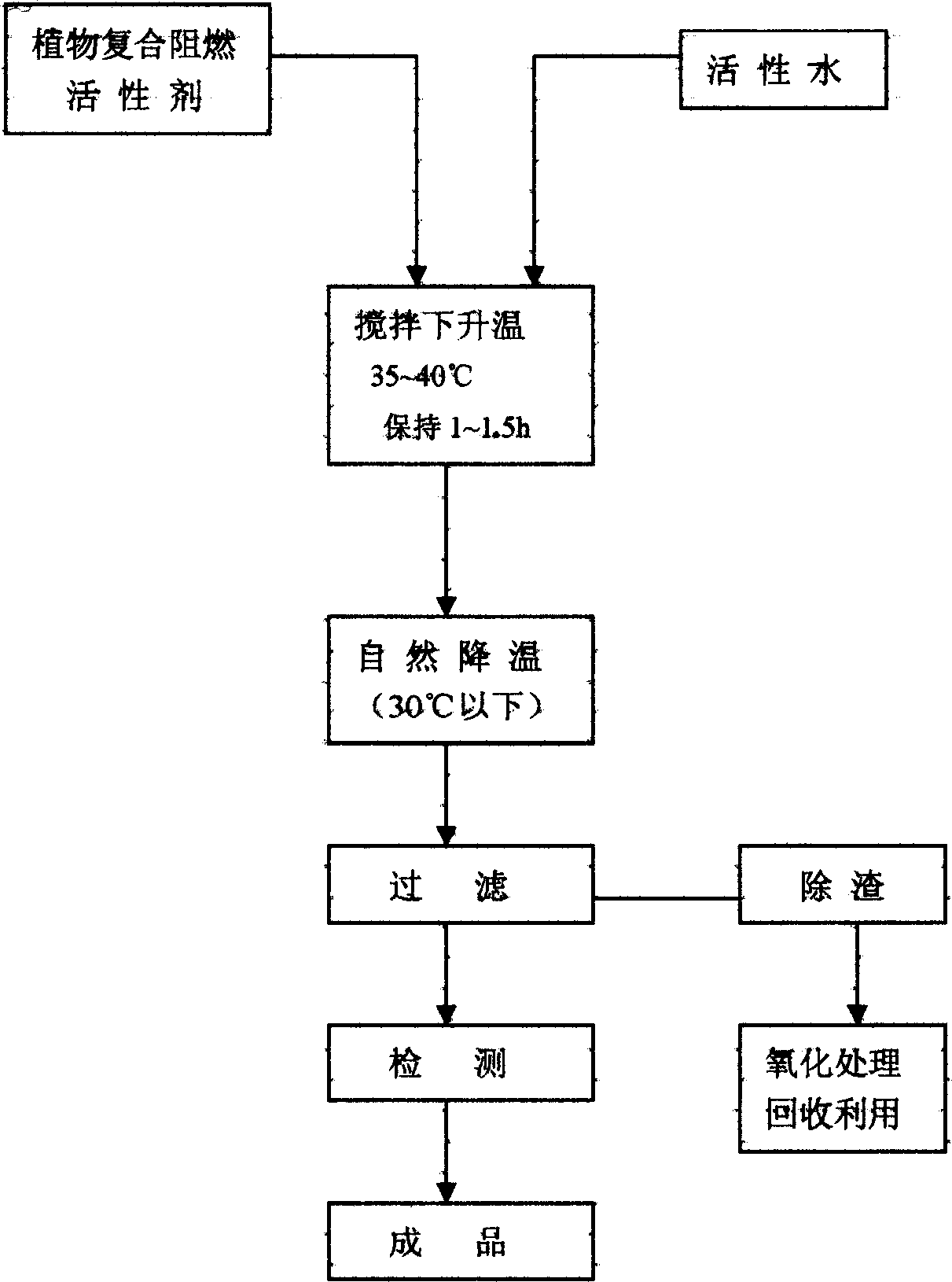

[0042] Take 88 parts of the above-mentioned active water, mix and stir with 12 parts of the plant composite flame retardant active agent, heat up to 40°C for 1 hour, naturally cool down to below 30°C, and take the clear liquid after filtering to obtain the plant active flame retardant according to the present invention. Natural fire extinguishing agent.

[0043] Mix it with water at a concentration of 6%, take 6L, put it into a portable fire extinguisher, put out Class A fire (wood fire) according to GB4351-1997 standard, the fire extinguishing energy is equal to 3A, and there is no re-ignition in 10 minutes. Compared with not using activated water and only diluting the plant composite fl...

Embodiment 2

[0045] Take 16 parts of dried melon distiller's grains, 3 parts of weed wood ash, add 91 parts of water, soak at room temperature for 24 hours, raise the temperature to 90°C and keep for 90 minutes, cool down to below 35°C, filter and take the clear liquid to obtain active water.

[0046] Take 90 parts of the above-mentioned active water, mix and stir with 10 parts of plant composite flame retardant active agent, heat up to 35°C and keep it warm for 1.5h, naturally cool down to below 30°C, and take the clear liquid after filtering to obtain the plant active agent of the present invention. Fire retardant fire extinguishing agent.

[0047] Mix it with water at a concentration of 6%, take 6L, put it into a portable fire extinguisher, and put out Class B fires (light oil fires) according to the GB4351-1997 standard, and the fire extinguishing energy is equal to 12B (2.4m 2 ), 30 minutes after the fire is extinguished, the open flame is ignited but does not burn.

[0048] Compared...

Embodiment 3

[0050] Take 16 parts of miscellaneous grain distiller's grains, 3 parts of weed wood ash, add 91 parts of water, soak at room temperature for 24 hours, raise the temperature to 90°C and keep it for 90 minutes, cool down to below 35°C, filter and take the clear liquid to obtain active water.

[0051] Take 85 parts of the above-mentioned active water, mix and stir with 15 parts of plant composite flame retardant active agent, raise the temperature to 38°C and keep it warm for 1.2h, naturally cool down to below 30°C, and take the clear liquid after filtering to obtain the plant active agent of the present invention. Fire retardant fire extinguishing agent.

[0052] Mix it with water at a concentration of 6%, take 6L, put it into a portable fire extinguisher, and use it to put out Class C fires (25L canned liquefied petroleum gas fires), the fire extinguishing time is 9s, and the consumption of the mixed solution is 2.5L.

[0053] Compared with not using active water and only dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com