Method and device for internal wall ceramic treatment of steel and iron pipe casting

A treatment method and ceramicization technology, applied in the direction of anodizing, superimposed layer plating, coating, etc., can solve the problems of great thermal influence of the substrate, difficult post-processing, difficult process, etc., and is conducive to unified recycling and installation. And the effect of convenient disassembly and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

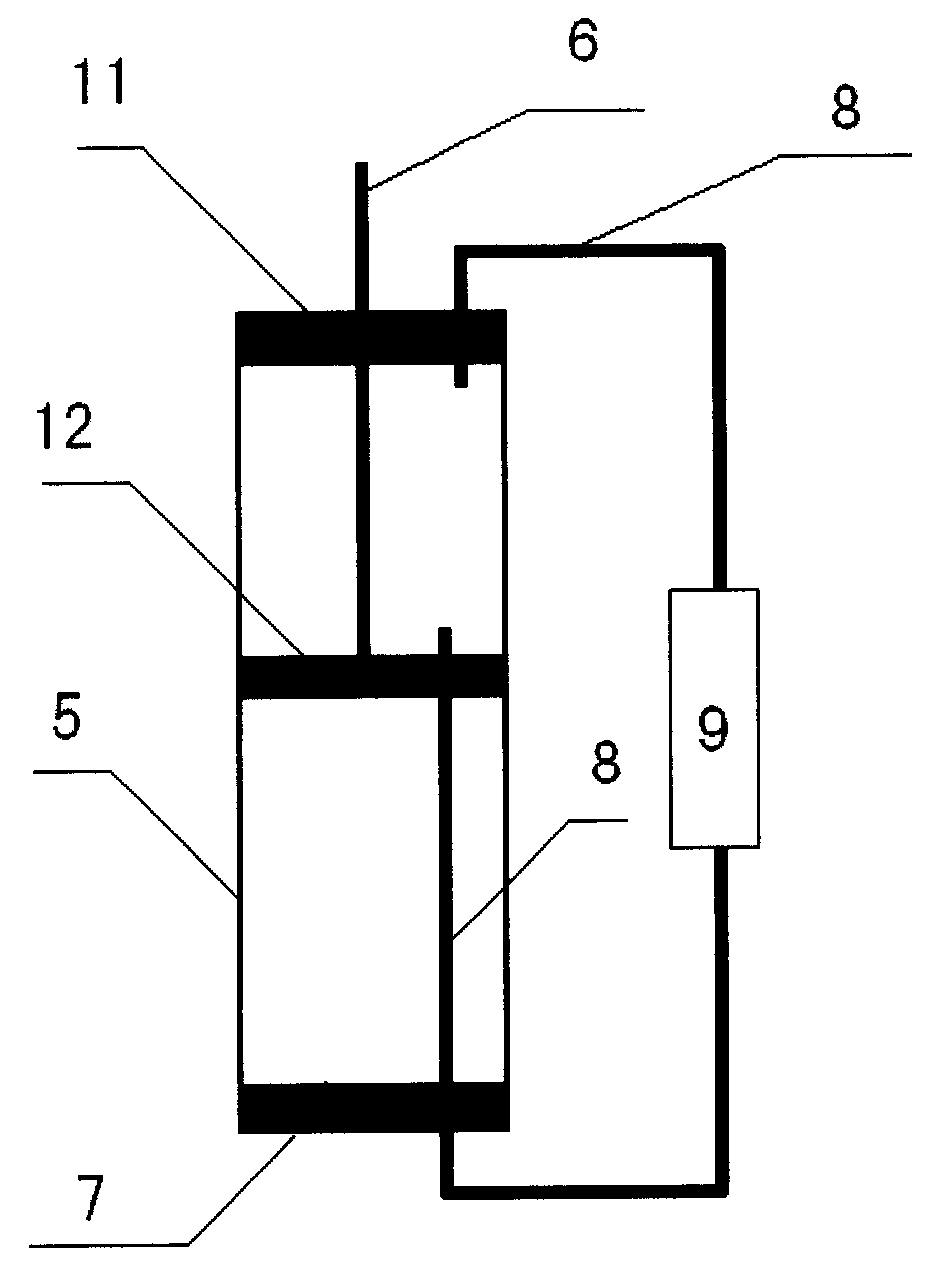

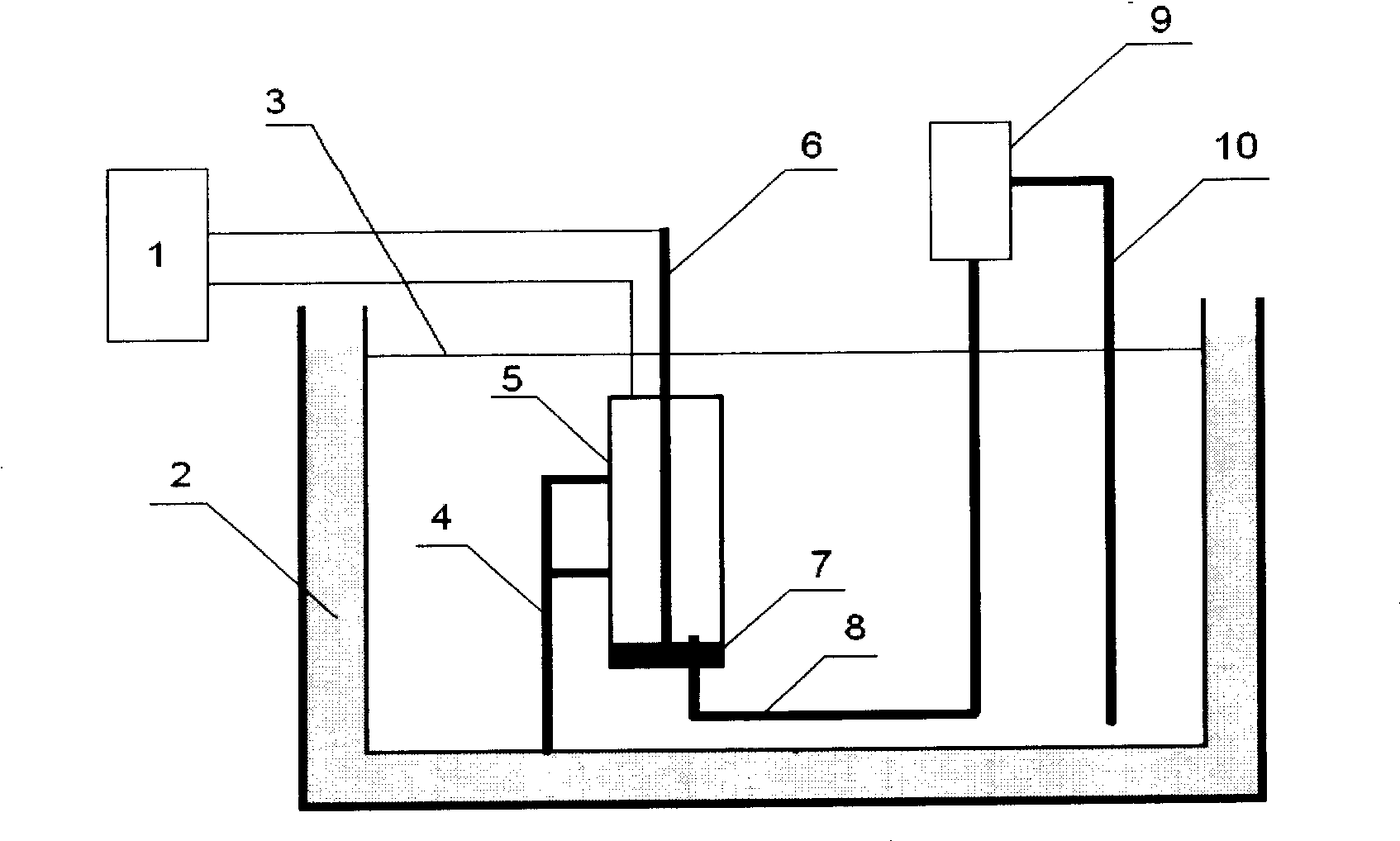

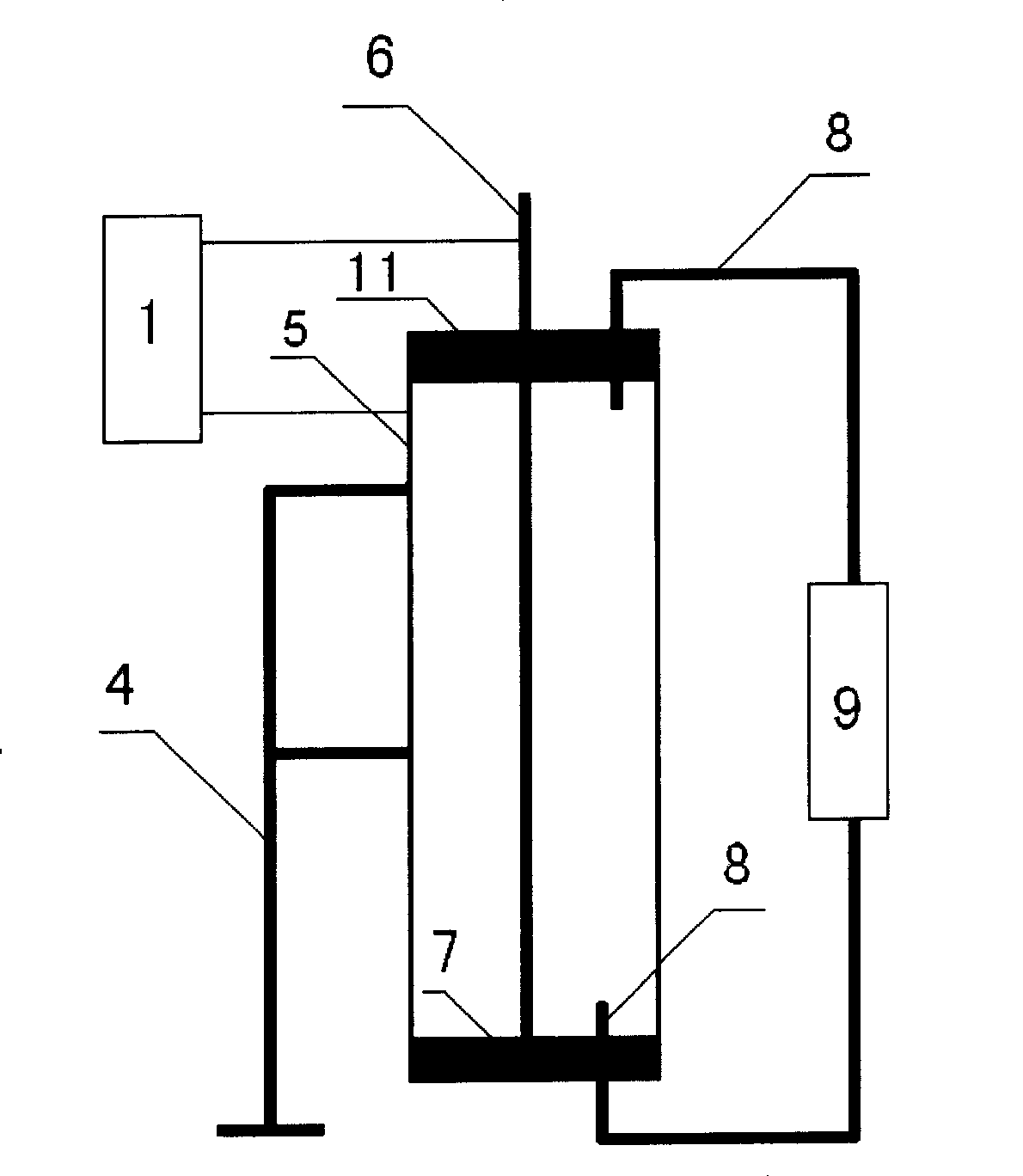

[0028] The invention provides a method for performing hot-dip aluminum plating on the surface of steel pipe fittings of various sizes, especially the surface of larger-sized steel pipe fittings, and then performing ceramic treatment on the hot-dip aluminum plating. Adopting the method can improve the bonding between the steel substrate and the ceramic layer on the one hand, and can form a uniform ceramic layer on the inner wall of the steel pipe fitting on the other hand to meet various use requirements. At the same time, the invention also provides a processing device for forming a layer of ceramic layer on the inner wall of the steel pipe fitting by adopting plasma electrolytic oxidation technology.

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] First, hot-dip aluminizing the inner and outer surfaces of the steel pipe fittings, immerse the steel pipe fittings in the aluminum liquid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com