Heat pump system for treating cold area after sewage-primary sewage

A technology for heat pump systems in cold areas, applied in heat pumps, sustainable biological treatment, biological water/sewage treatment, etc. The effect of high utilization efficiency, fast heat conduction and large energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

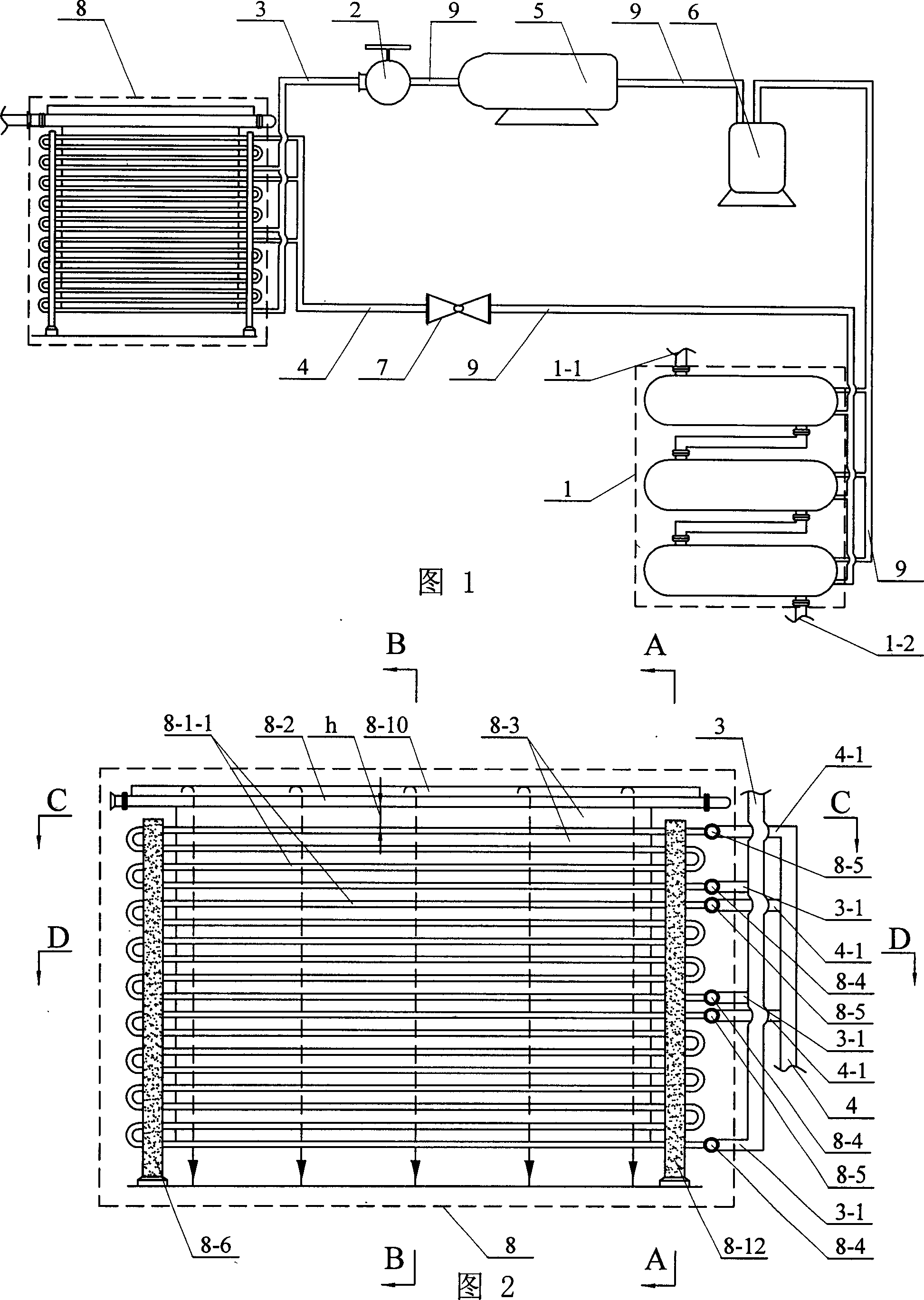

[0006] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1. This embodiment consists of a three-stage shell-and-tube evaporator 1, a check valve 2, a refrigerant inlet pipeline 3, a refrigerant outlet pipeline 4, a compressor 5, a gas The liquid separator 6, the expansion valve 7, the three-stage shower condenser 8, and the refrigerant pipeline 9 are composed; the outlet end of the compressor 5 is fixedly connected with the inlet end of the one-way valve 2 through the refrigerant pipeline 9, and the one-way The outlet end of the valve 2 is fixedly connected to the inlet end of the three-stage shower condenser 8 through the refrigerant inlet pipeline 3, and the outlet end of the three-stage shower condenser 8 is connected to the expansion valve 7 through the refrigerant outlet pipeline 4. The inlet end is fixedly connected, the outlet end of the expansion valve 7 is fixedly connected to the inlet end of the evaporator 1 through the refrigerant pipeline...

specific Embodiment approach 2

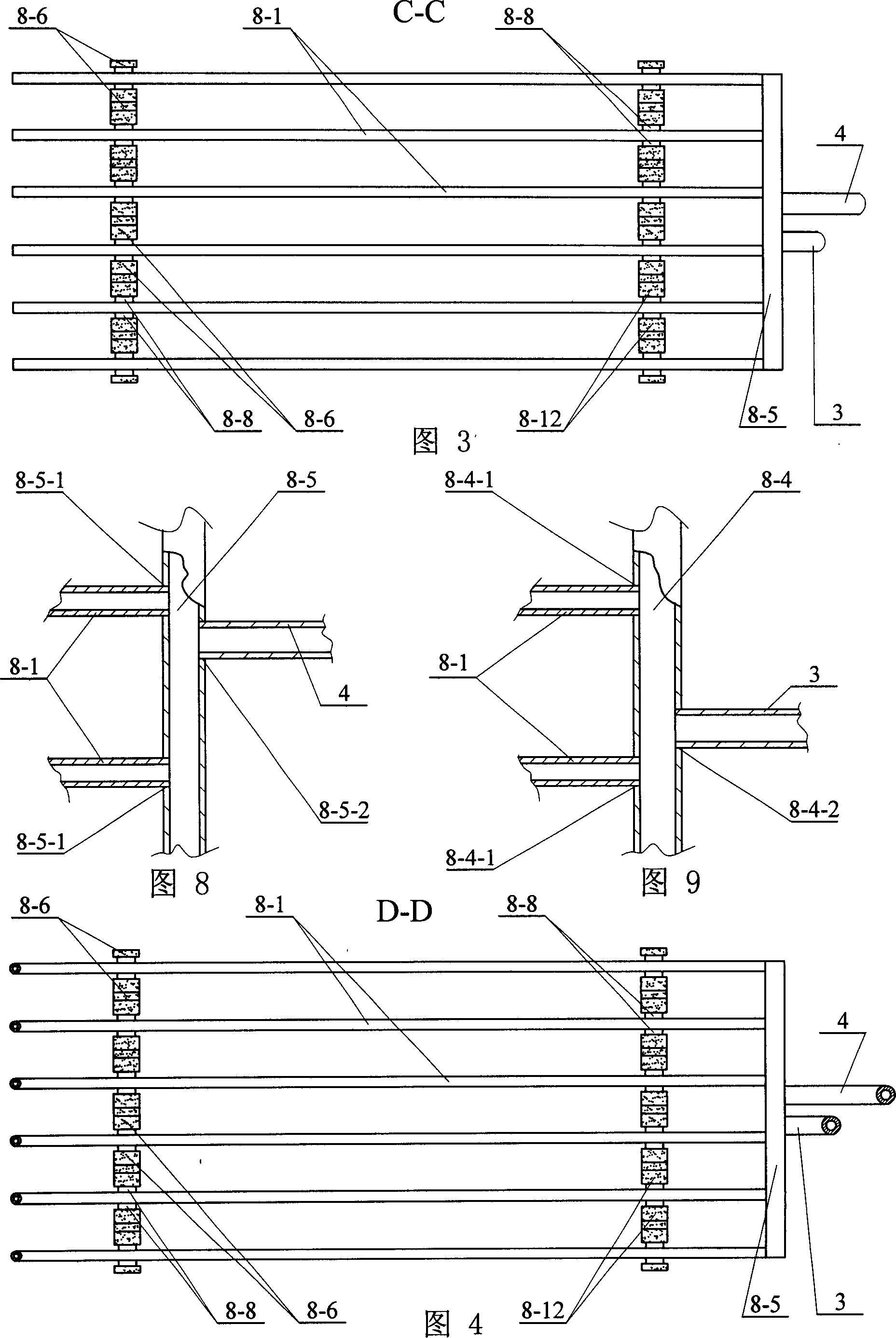

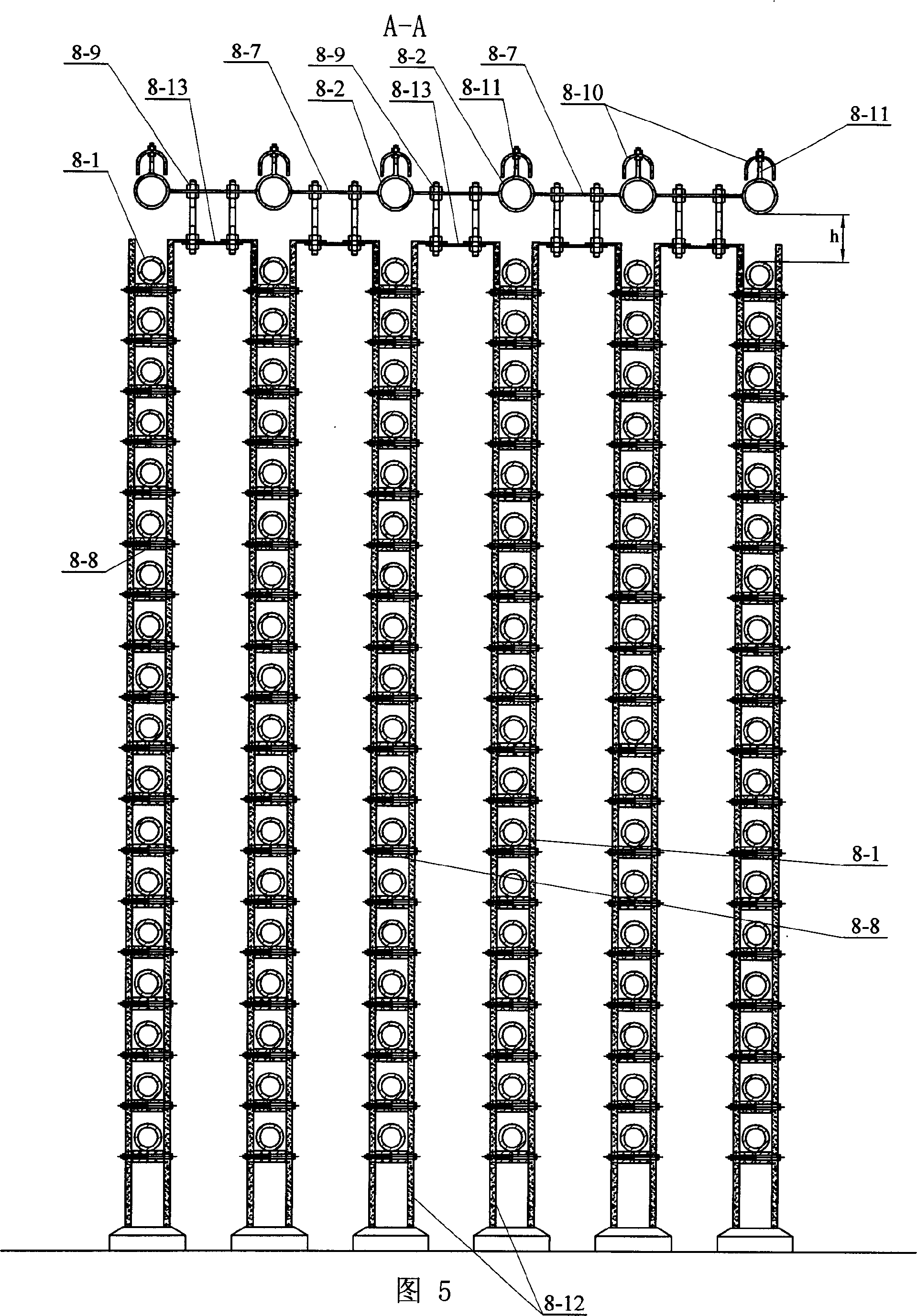

[0007] Specific embodiment two: in conjunction with Fig. 2, Fig. 3, Fig. 4, Fig. 5, Image 6 , Fig. 8 and Fig. 9 illustrate the present embodiment, the three-stage shower condenser 8 of the present embodiment consists of a group of spray coils placed side by side, a water shower 8-2, a dripping plate 8-3, and a liquid separator 8 -4. Composed of liquid collecting pipe 8-5, bracket, connecting frame 8-7, bracket spacing adjustment device 8-8, and connector 8-9; each row of spray coils 8-1 is respectively installed in the corresponding bracket, Each horizontal pipe 8-1-1 on the spray coil 8-1 of each column is installed on the bracket spacing adjustment device 8-8 respectively, and the two ends of the bracket spacing adjustment device 8-8 are connected with the bracket respectively. There is a shower pipe 8-2 above the shower snake pipe 8-1, and the distance between the top of each row of shower snake pipe 8-1 and the bottom end of the corresponding shower pipe 8-2 is h, and the ...

specific Embodiment approach 3

[0009] Specific embodiment three: This embodiment is described in conjunction with Fig. 2, Fig. 3, and Fig. 4. The difference between this embodiment and specific embodiment two is: the bracket of this embodiment is composed of a left bracket 8-6 and a right bracket 8-12 ; The left end of each row of spray coils 8-1 is fixed in the corresponding left bracket 8-6, the right end of each row of spray coils 8-1 is fixed in the corresponding right bracket 8-12, and the left bracket 8-6 On the outer wall of the bottom end of the shower pipe 8-2 between the right bracket 8-12 and on the outer wall of the bottom end of each horizontal pipe 8-1-1 on each row of spray coils 8-1, they are respectively fixedly connected along the axial direction There are 8-3 drop plates. The left bracket 8-6 and the right bracket 8-12 are used to fix each row of spray coils 8-1, which has the advantages of firm fixing and easy installation and disassembly.

[0010] Embodiment 4: This embodiment is descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com