Aluminium alloy laser welding wire-feeding mechanism

A wire feeding mechanism and laser welding technology, applied in laser welding equipment, welding equipment, arc welding equipment, etc., can solve the problems affecting the stability of the welding process, aluminum welding wire indentation, small contact area, etc., and achieve stable and reliable wire feeding , Large wire feeding force, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

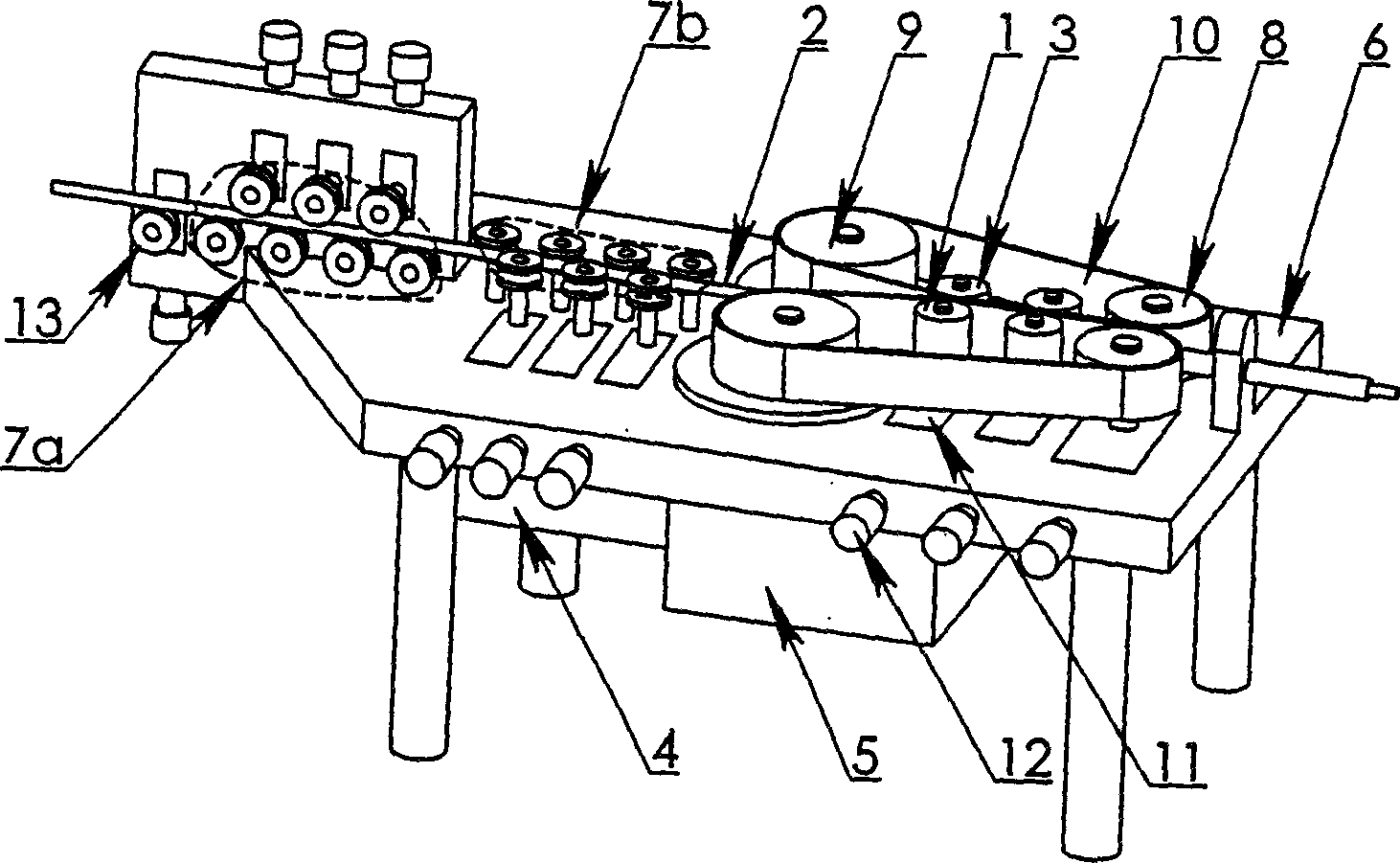

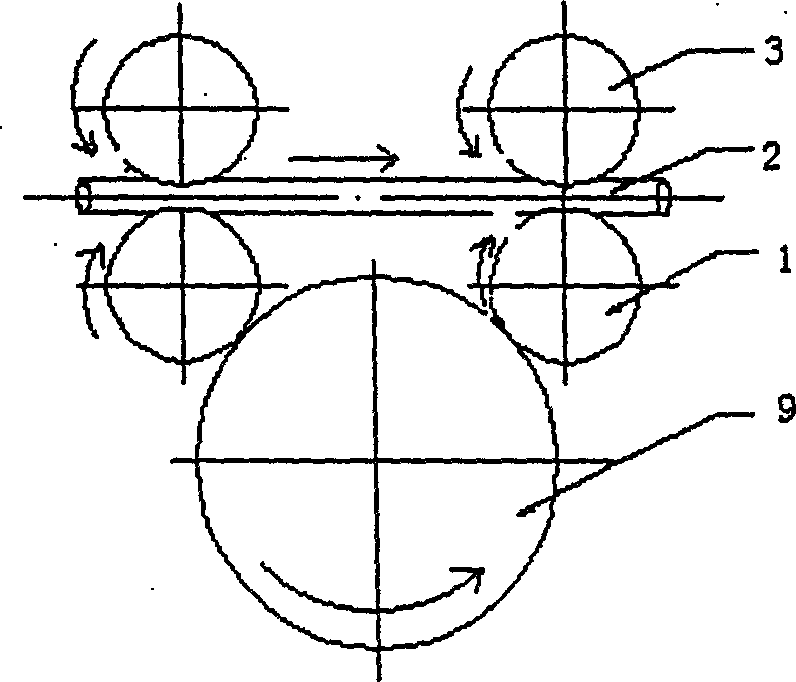

[0019] The structural schematic diagram of an embodiment of the aluminum alloy laser welding wire feeding mechanism of the present invention is as follows figure 1 As shown, it includes a frame 6, a driving wheel 9 connected to the frame 6, a driven wheel 8, a motor 4, a reducer 5, an upper pressing roller 3, and a lower pressing roller 1, as well as a set of rollers arranged in sequence along the wire feeding direction. Position adjustment wheel 13, longitudinal straightening roller group 7a, horizontal straightening roller group 7b, two clamping flat belts 10 arranged between the upper pressing roller 3 and the aluminum welding wire 2, and between the lower pressing roller 1 and the aluminum welding wire 2 ; Wherein, the motor 4 and the reducer 5 are fixed below the frame 6, the motor 4 is fixedly connected to the reducer 5, the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com