Hybrid laser machining method and hybrid laser torch used therein

A laser processing method and laser head technology, which are applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of sputter particle pollution, spray spatter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

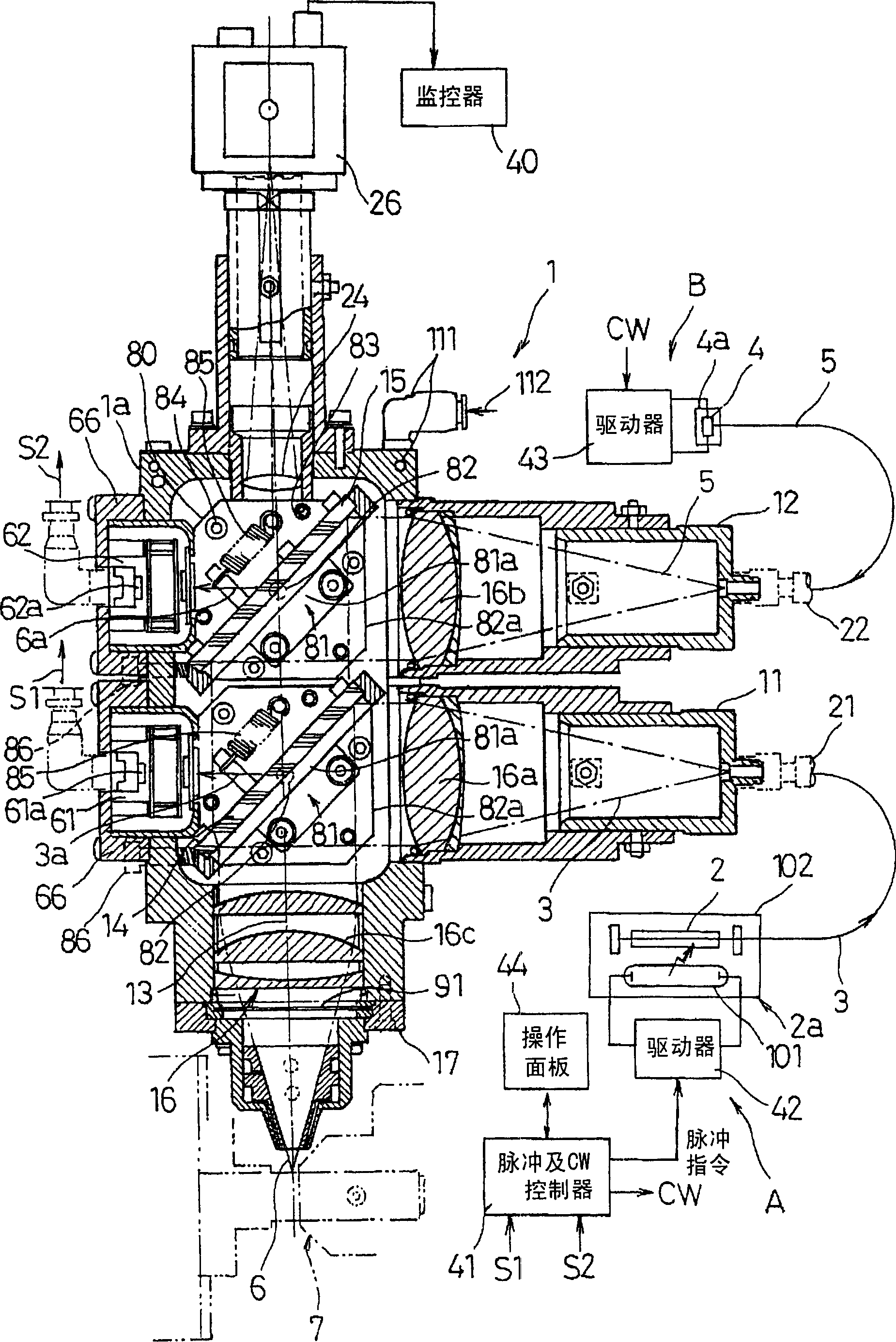

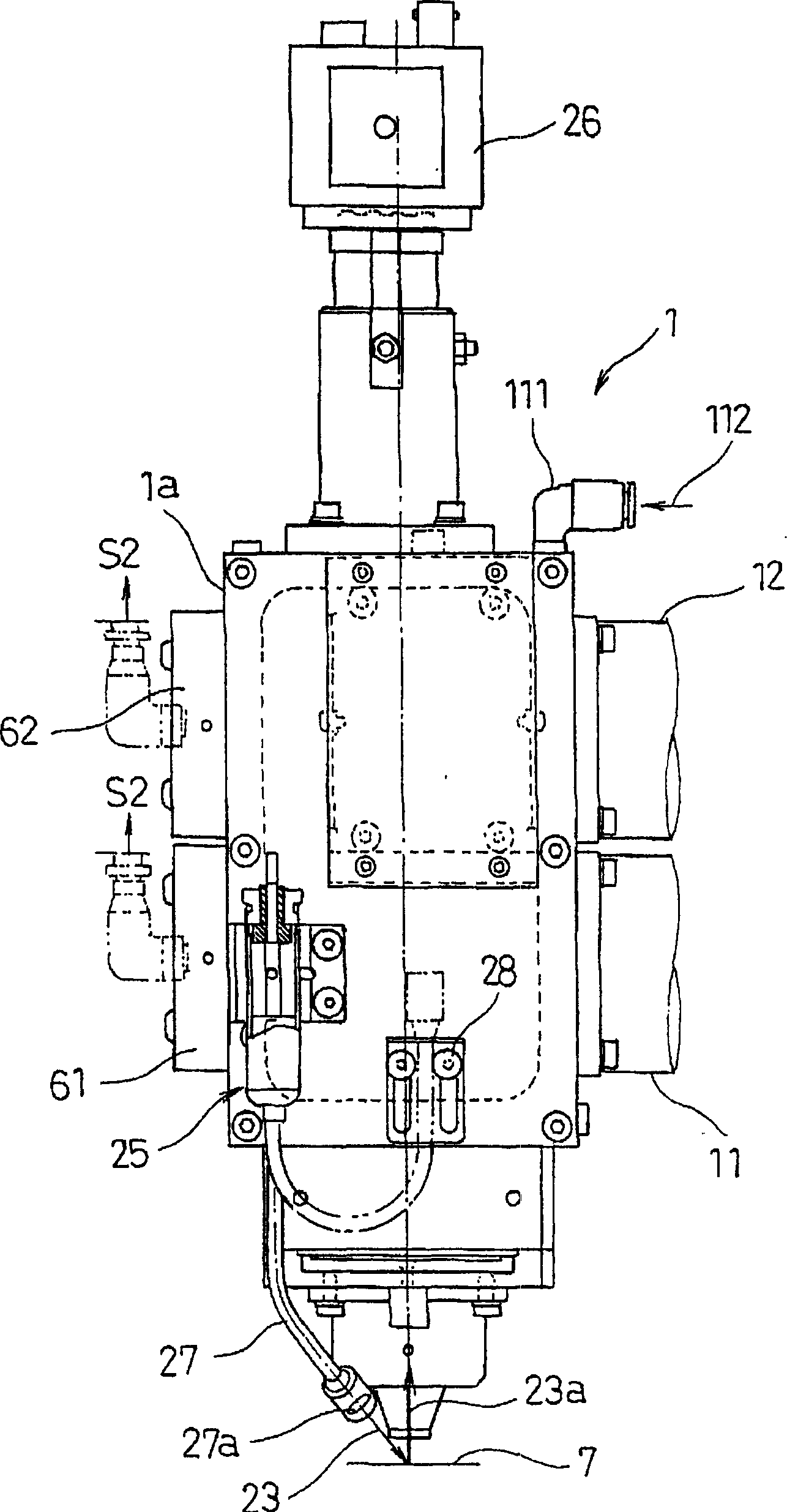

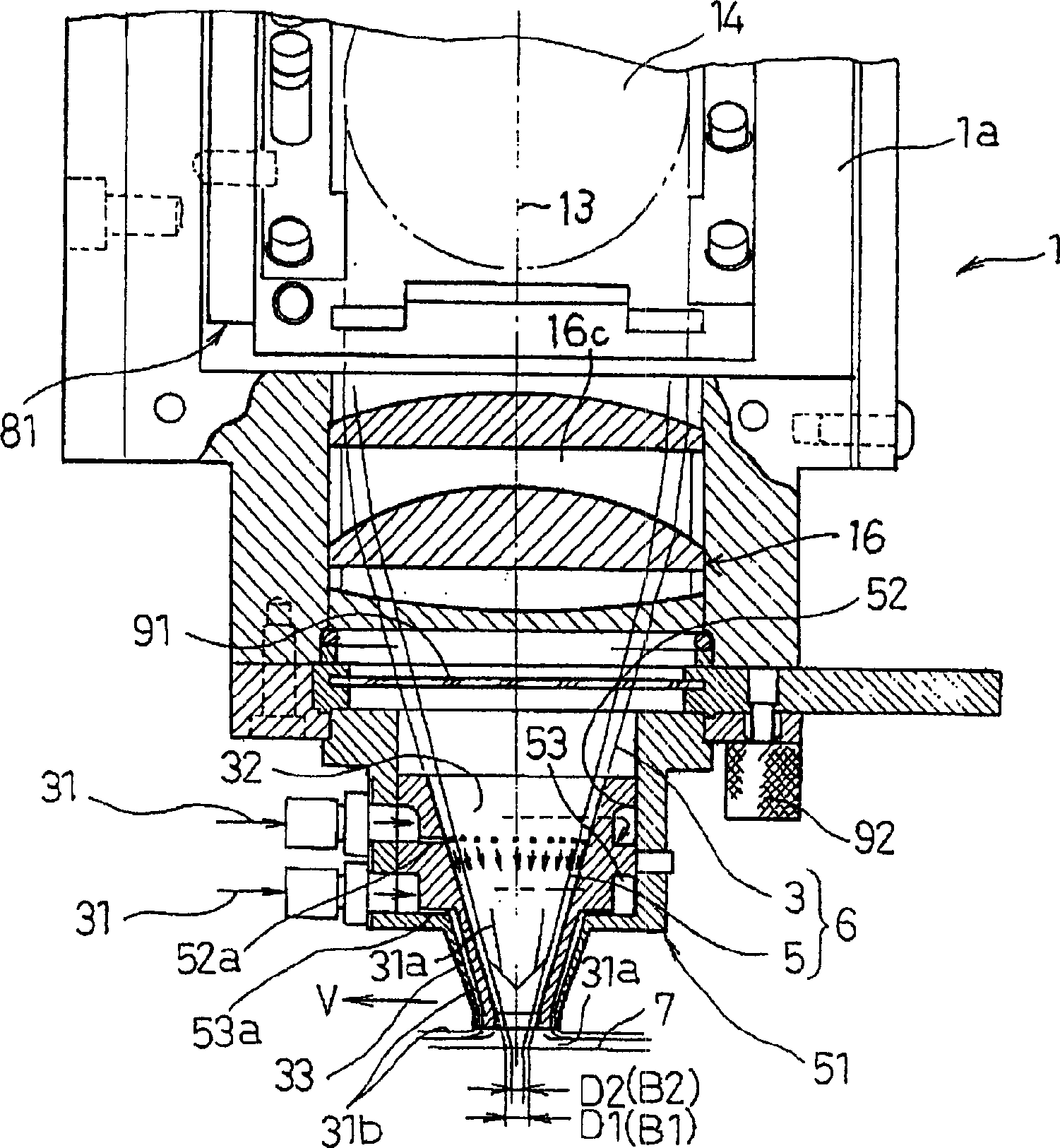

[0093] Refer to the following Figure 1 to Figure 7 , to describe in detail the hybrid laser processing method and the hybrid laser head used in the method according to the embodiment of the present invention, for the understanding of the present invention. In addition, the following description is a specific example of this invention, and it does not limit the description of the scope of a claim.

[0094] The hybrid laser processing method related to this embodiment refers to figure 1 The hybrid laser head 1 shown, in order to irradiate the object 7 to be processed with different first and second laser beams 3 from two kinds of laser systems A and B and as a hybrid laser beam 6, as image 3 Focusing is carried out as shown, so that the focus diameter and effective spot size D2 of the second laser 5 in the mixed laser 6 on the processed object 7 are smaller than the focus diameter and effective spot size D1 of the first laser, so that the irradiation is Process the object 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com