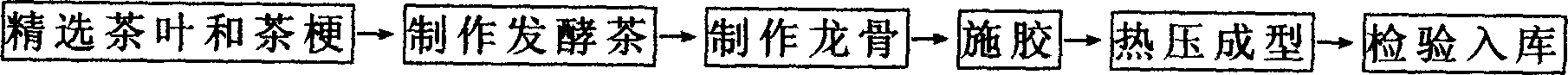

Environmental protection tea composite board material and its processing method

A technology of composite board and processing method, which is applied to wood processing appliances, manufacturing tools, and other household appliances, etc., can solve the problems of low pH value, increased formaldehyde emission, poor curing degree, etc., and achieve the effect of purifying the air in the room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

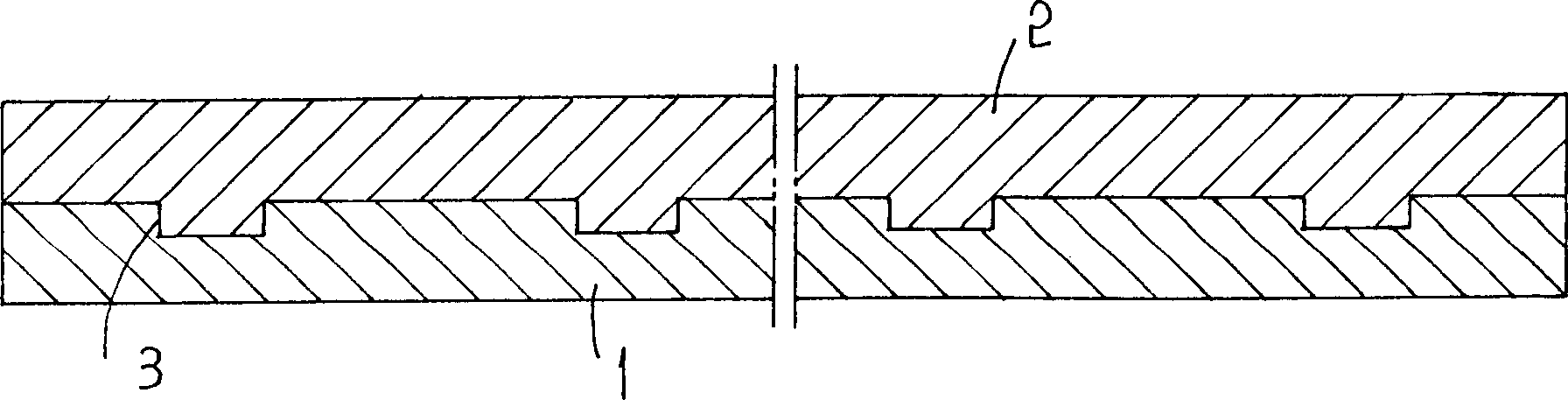

[0042] 2cm thick standard OSB wood shaving tea medium density composite board for furniture wall cabinets

[0043] 1) Choose a medium density fiberboard hot press machine;

[0044] 2) Choose a 1cm OSB board, make a cross, 1cm wide × 0.3cm deep tenon and groove, and the tenon and groove interval is 3cm;

[0045] 3) 50 kg of loose tea fermented by fermented heaps of selected tea leaves and tea stems in a ratio of 7:3, and fully stirred evenly with the environmentally friendly adhesive in a ratio of 1:9;

[0046] 4) Lay the tea raw material on the grooved side of the OSB board, and press it on the machine according to the MDF production specification. Refer to the cross-sectional shape of the product figure 2 shown.

Embodiment 2

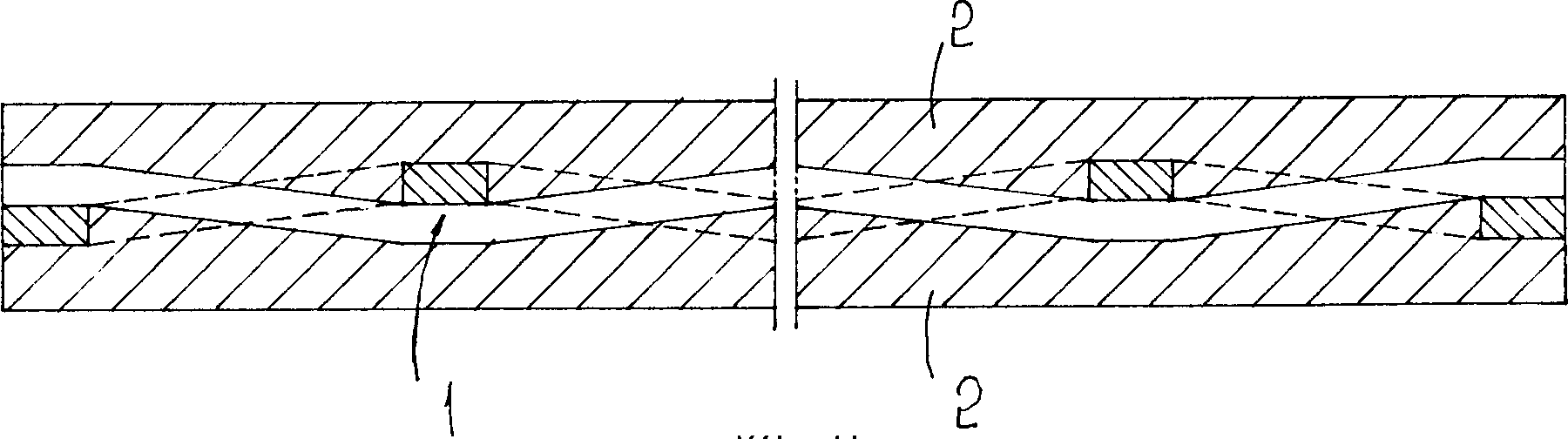

[0048] Environmentally friendly tea high-density composite boards for making furniture wall cabinets.

[0049] 1) Choose a high-density fiberboard hot press;

[0050] 2) Bamboo strips with a width of 0.8cm are selected and cross-woven into standard bamboo strips, with an interval of 3cm between bamboo strips;

[0051] 3) 50 kg of loose tea fermented by fermented heaps of selected tea leaves and tea stems in a ratio of 7:3, and fully stirred evenly with the environmentally friendly adhesive in a ratio of 1:9;

[0052] 4) Lay 25kg of tea raw material on the machine first, then pave bamboo slats, and then lay 25kg of tea raw material on it, and make standard hot-press molding according to the high-density fiberboard specification.

[0053] Refer to the cross-sectional shape of the product image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com