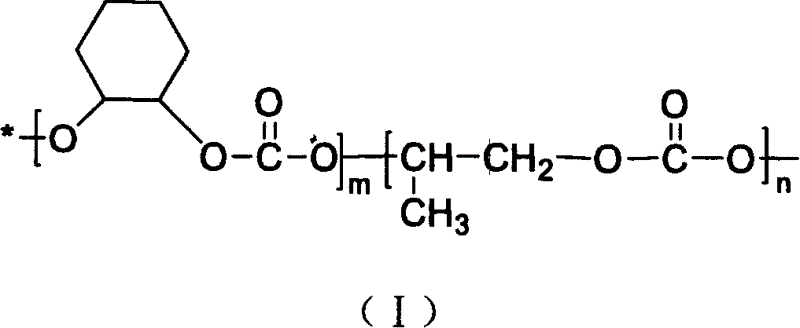

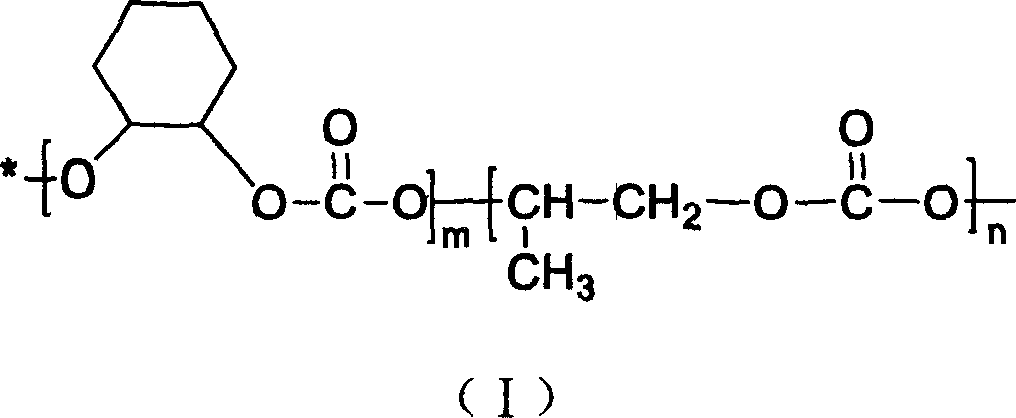

Poly methyl ethylene cyclo hexamethylene carbonate material and its preparation method

A polymethylethylene and cyclohexene technology is applied in the field of polymethylethylene-cyclohexene carbonate materials and their preparation, which can solve problems such as poor mechanical properties and thermal properties, achieve performance improvement, and improve mechanical properties. Performance and thermal properties, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Add 1g of supported zinc dicarboxylate catalyst into a 0.5L autoclave equipped with a stirrer, connect the entire reaction system to a vacuum system, and then vacuum-dry the autoclave that has been placed in the pre-weighed catalyst at 80°C for 24h . After drying, drop to room temperature, inject a certain proportion of propylene oxide and cyclohexane oxide into the autoclave, and feed carbon dioxide, heat, start stirring, adjust the pressure of carbon dioxide to 5.2Mpa, make the reaction system between 5.2Mpa and React at 60°C for 40 hours. After the reaction was over, carbon dioxide was released, and the viscous mixture in the kettle was taken out. This mixture was dissolved in chloroform, and the catalyst in the system was removed with 5% dilute hydrochloric acid solution, and washed three times with distilled water. Then adjust the chloroform solution of the obtained copolymer to a certain concentration, and then use ethanol to precipitate, and the obtained white ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap