Clutch with intertial jointing

A clutch and inertia technology, applied in clutches, automatic clutches, mechanical equipment, etc., can solve problems such as large power transmission loss, easy heat generation, and incomplete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

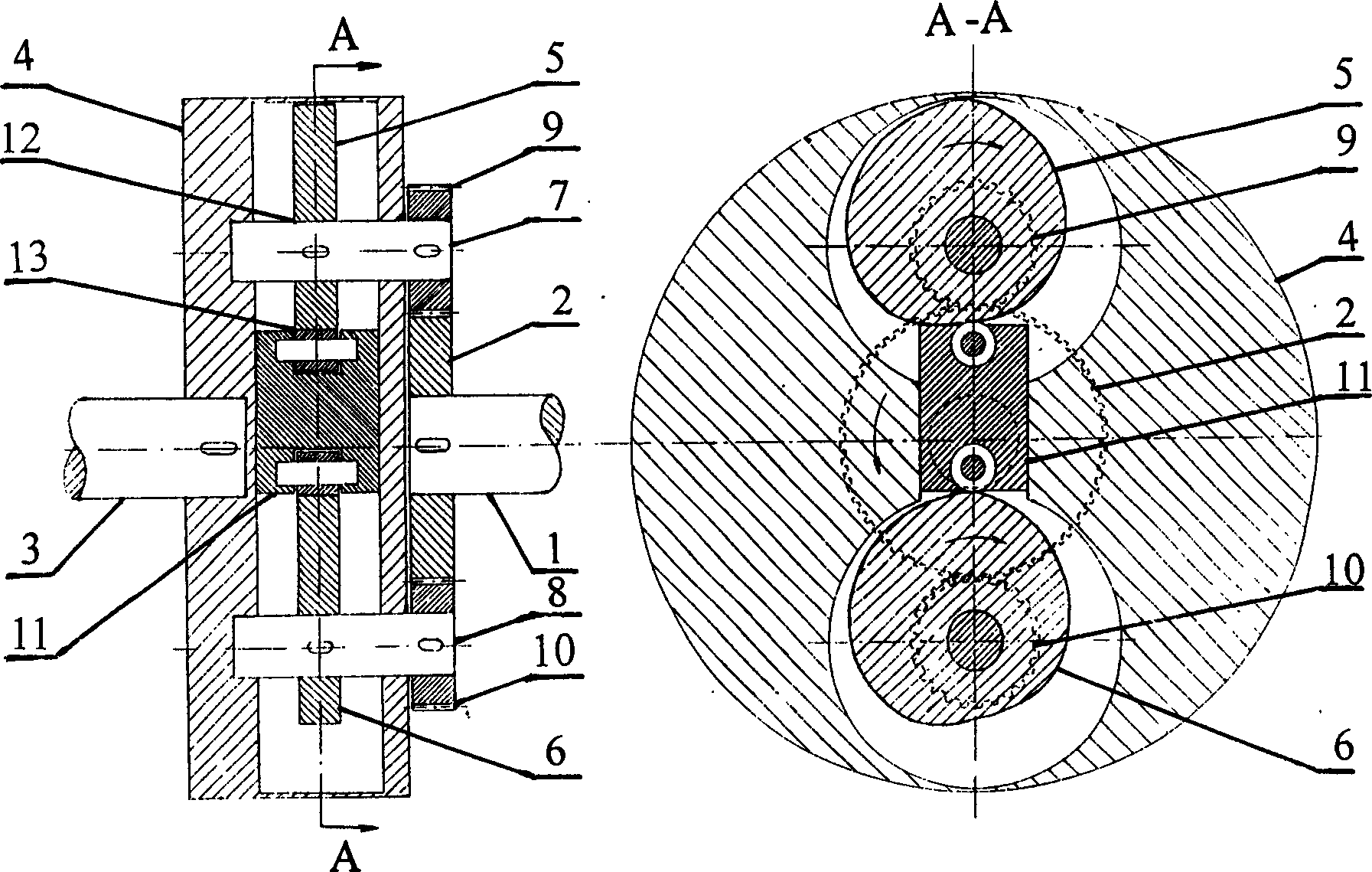

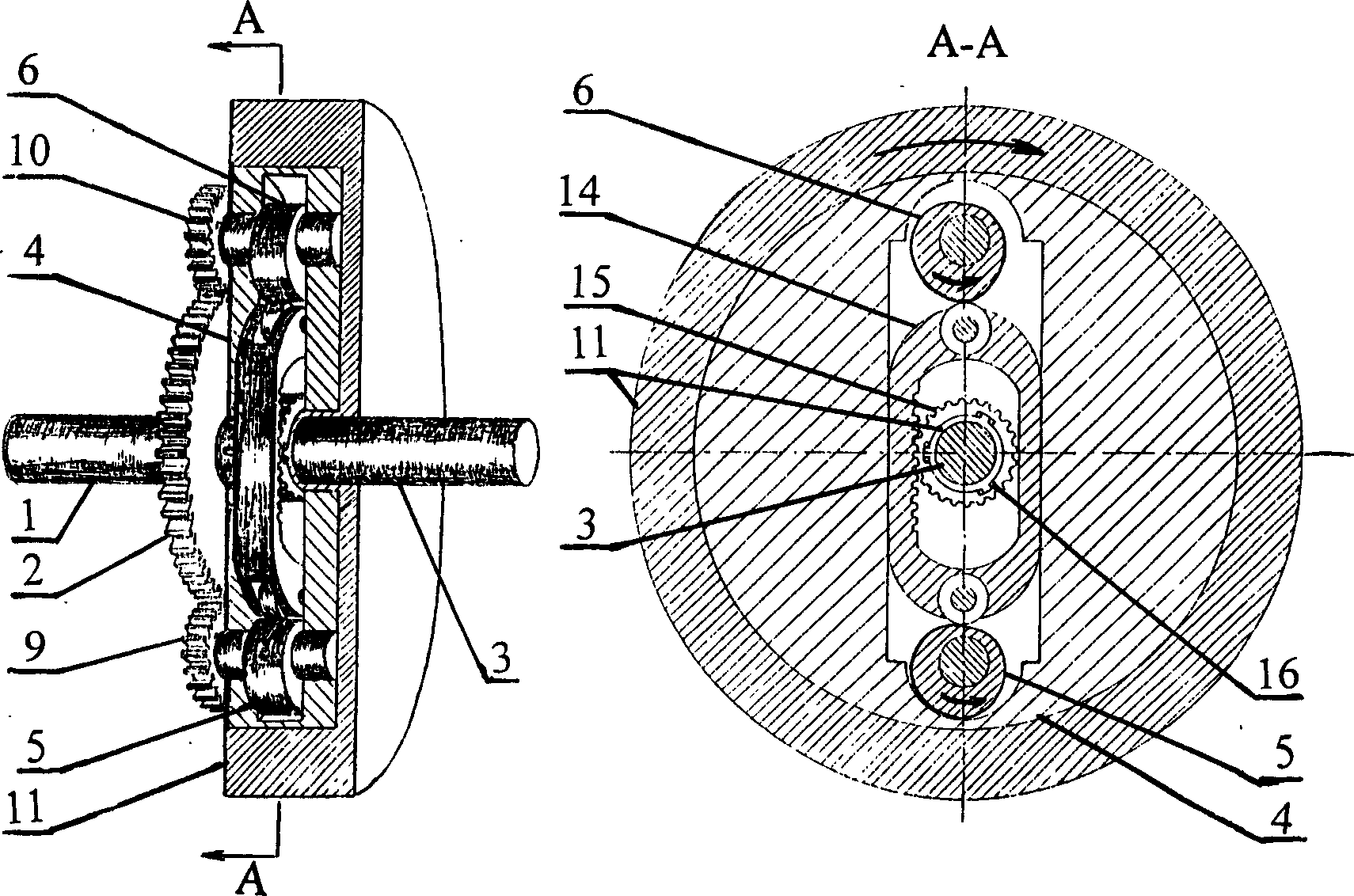

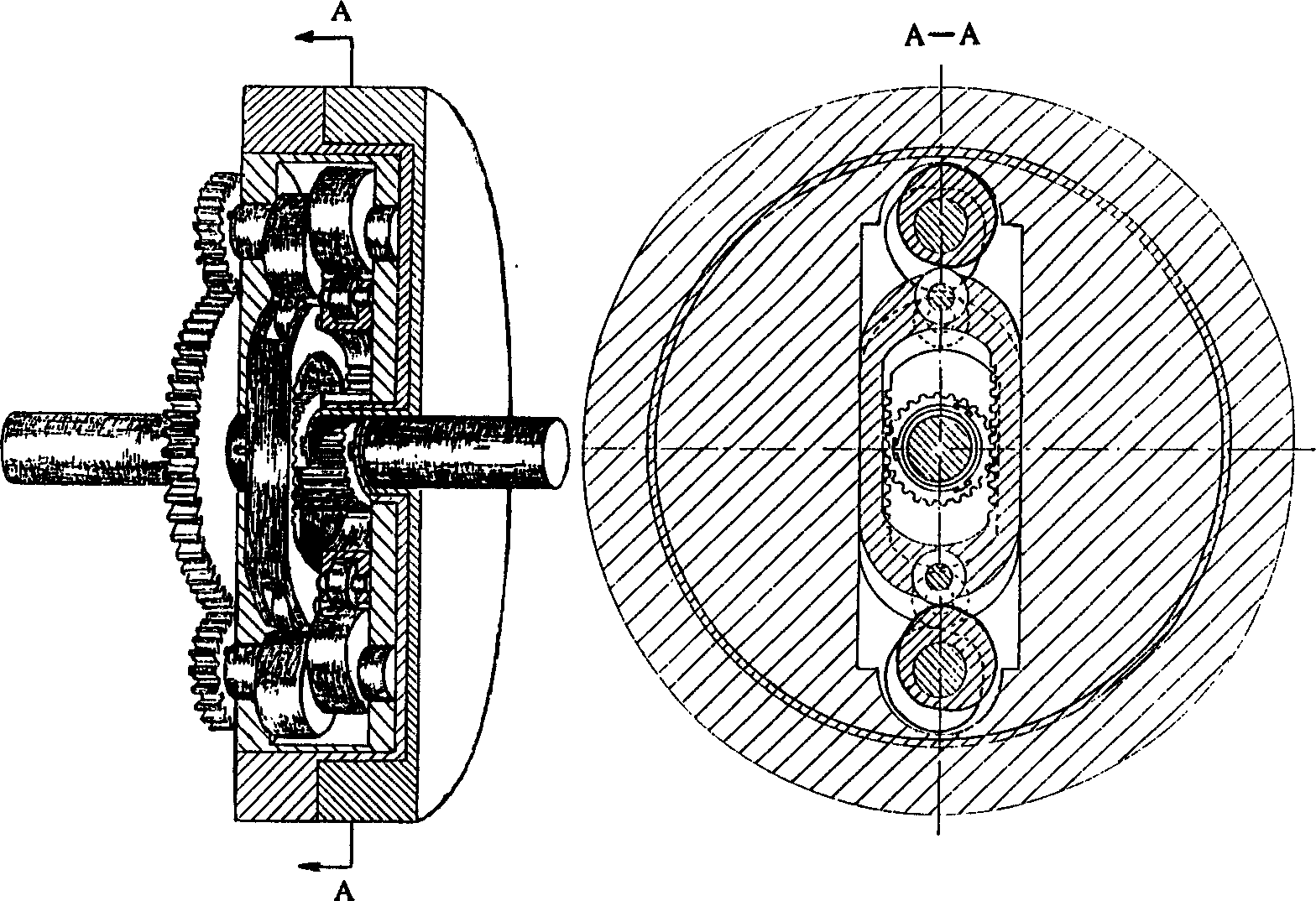

[0020] Such as figure 1 As shown, the clutch is mainly composed of: input shaft (1), input gear (2), output shaft (3), output turntable (4), cam (5), cam (6), camshaft (7), camshaft (8), transmission gear (9), transmission gear (10), and the pendulum (11) between two cams (5) cams (6), composition. Wherein transmission gear (9) and transmission gear (10) are two gears that are equal in size and the same number of teeth, and cam (5) and cam (6) are also identical, mainly here it is represented respectively for the ease of explanation of working principle.

[0021] When the input gear (2) rotates in the direction of the arrow in the drawing relative to the output turntable (4), the transmission gear (9) and the transmission gear (10) meshed with the input gear (2) drive the cam (5) and the cam (6) respectively. ) to rotate in the direction of the arrow in the drawing. Due to the effect of the profile curve of the cam (5), the stationary pendulum (11) is forced to move towards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com