Thickness measuring method for organic coating film on metal surface

A thickness measurement and film thickness technology, applied in measurement devices, color/spectral characteristics measurement, semiconductor/solid-state device testing/measurement, etc., can solve the problems of complexity and poor reliability, and achieve the effect of reducing any errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

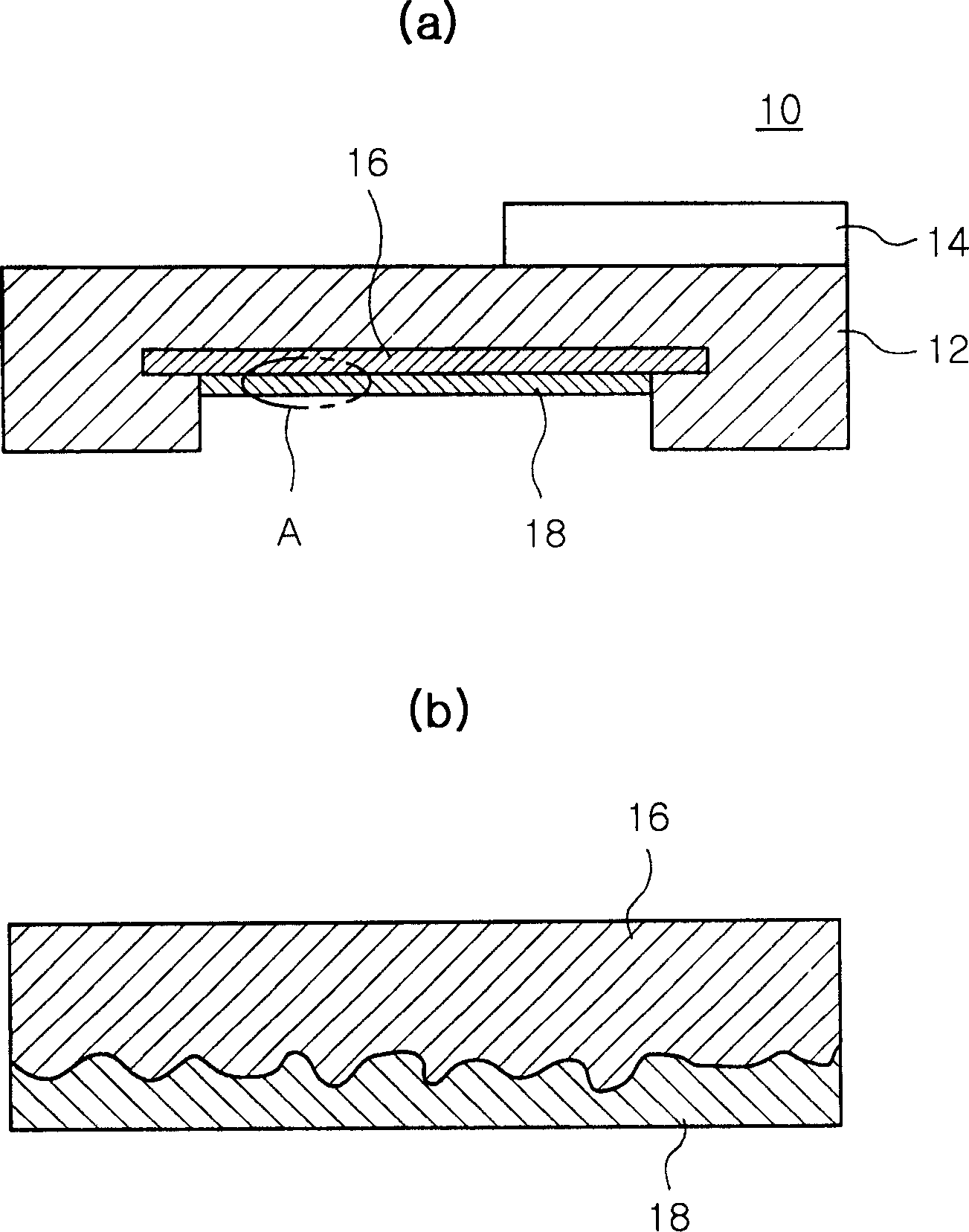

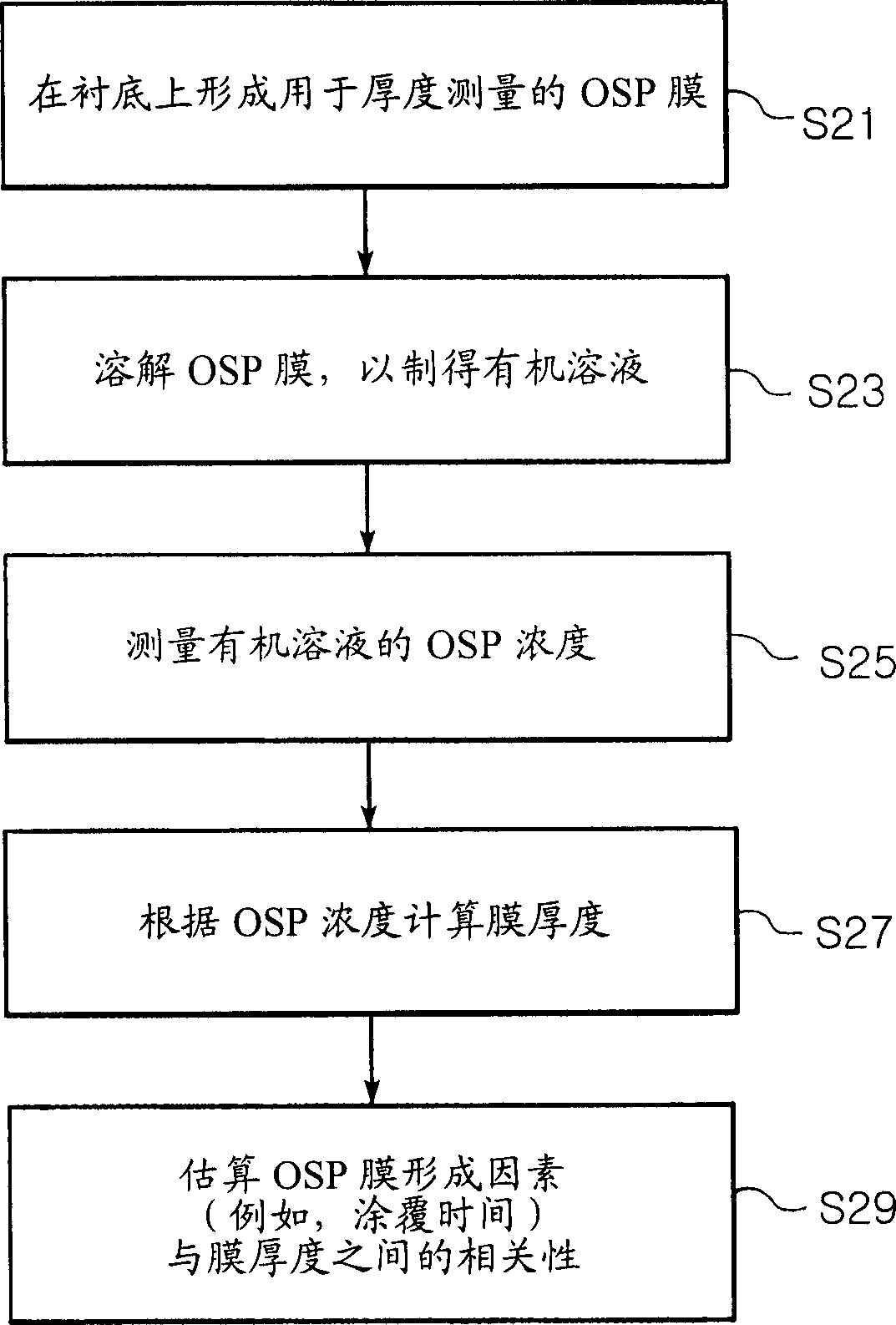

[0057] Place four (4) 10cm 2 A copper laminated plate was prepared as the substrate used in the thickness measurement. The copper surfaces of these laminates were cleaned and then etched under the same conditions as for conventional copper pads. Aqueous solutions of Alkil-benzene-imidazole (Alkil-benzene-imidazole) were applied to the surface of these 4 copper laminates for different time periods, and then water was removed from the copper laminates to prepare four reference organic coatings. Films A to D.

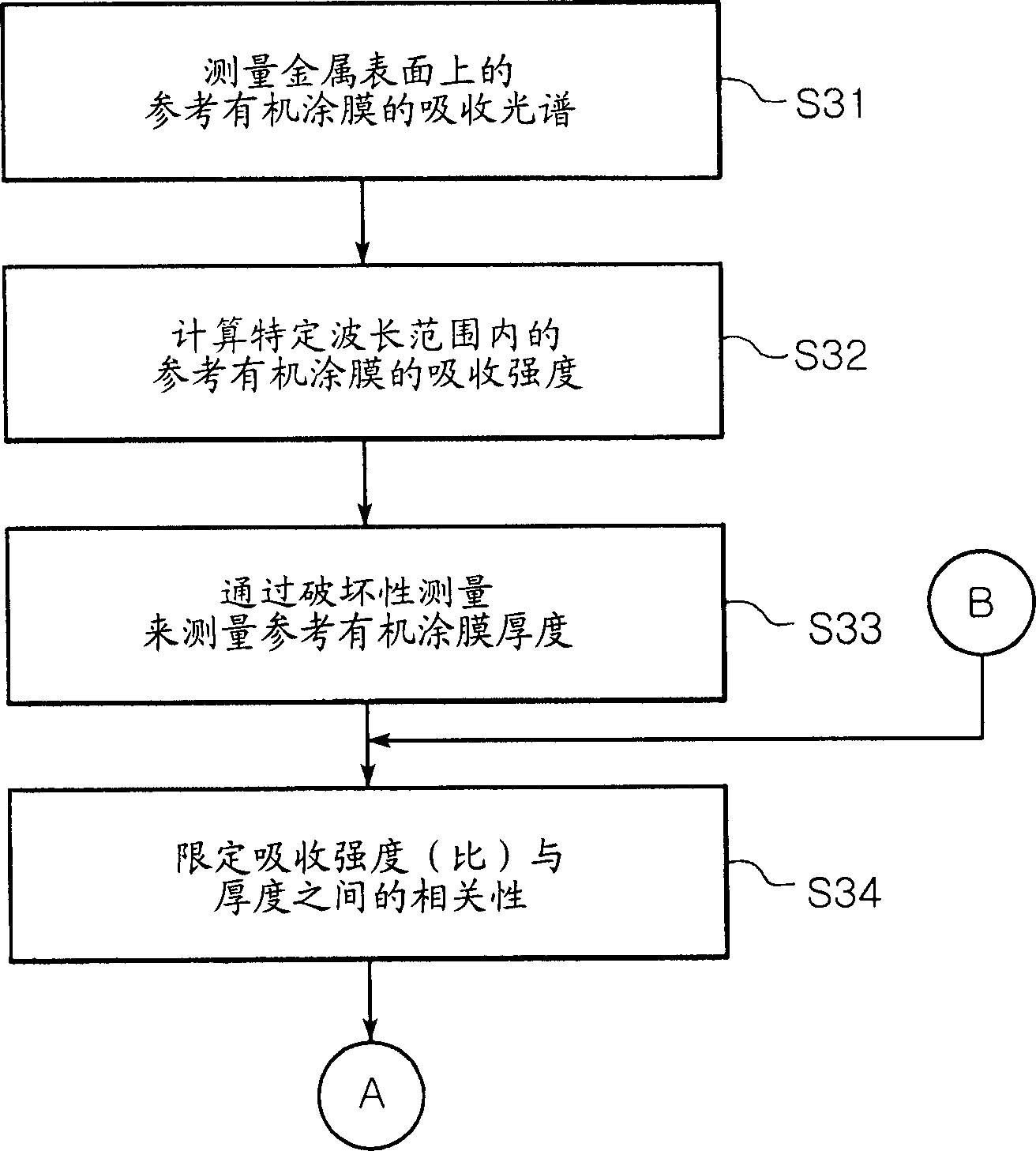

[0058] According to the FT-IR technique, IR absorption spectra were measured from these four reference organic coating films. Calculated from the measured IR absorption spectrum by integration from 1230 to 1290cm -1 range of absorption strength. The organic coating films exhibited absorption intensity values of 15, 99.5, 153, and 160. Figure 6 a is a graph showing the IR absorption spectrum with respect to the reference organic coating film D. FIG.

[0059] Then, ...

example 2

[0063] Example 2 is applied to the thickness measurement method of the present invention by converting the correlation between the absorption intensity and thickness of the reference organic coating film obtained from Example 1, based on the absorption intensity information of the external standard material, into the absorption intensity ratio and A more precise correlation between thicknesses.

[0064] First, perylene was coated onto a highly polished Si wafer with a coating thickness of 1.2 μm, and absorption spectrum measurement was performed by IR spectroscopy. Plot the measured spectrum on Figure 7 a. Measure 1380 to 1520cm -1 The absorption intensity in the wavelength range, and the absorption intensity of the reference organic coating film measured in Example 1 was divided by the absorption intensity of perylene (about 765) to obtain the absorption intensity ratio. Absorption intensity ratios associated with organic coating films were 0.02, 0.13, 0.2, and 0.21. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com