Silicon micro condenser microphone chip and its preparing method

A condenser microphone and silicon micro technology, applied in the direction of electrostatic transducer microphones, sensors, electrical components, etc., can solve the problems of large influence, long time consumption, high cost of silicon micro capacitor microphone chip, etc., achieve simple and easy process, overcome problems and difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

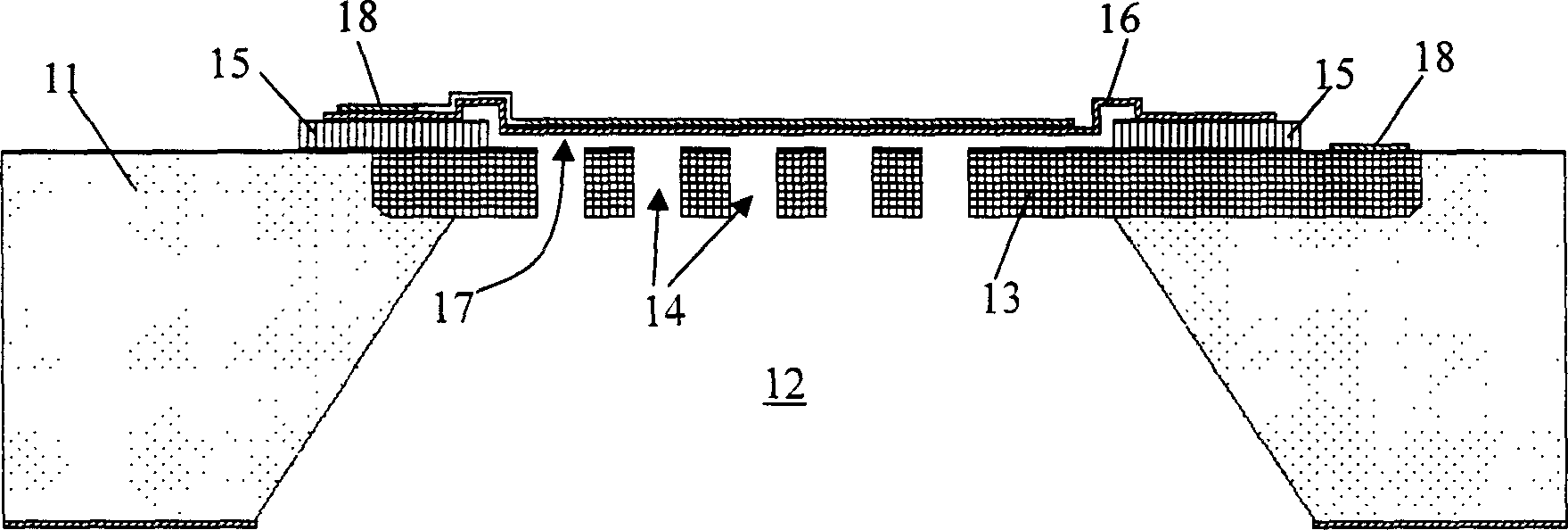

[0039] figure 2 ~ Fig. 5 shows the preparation process of the silicon microcapacitance microphone chip of the present invention in one embodiment, wherein Fig. 5 shows the prepared microphone chip according to the method of the present invention.

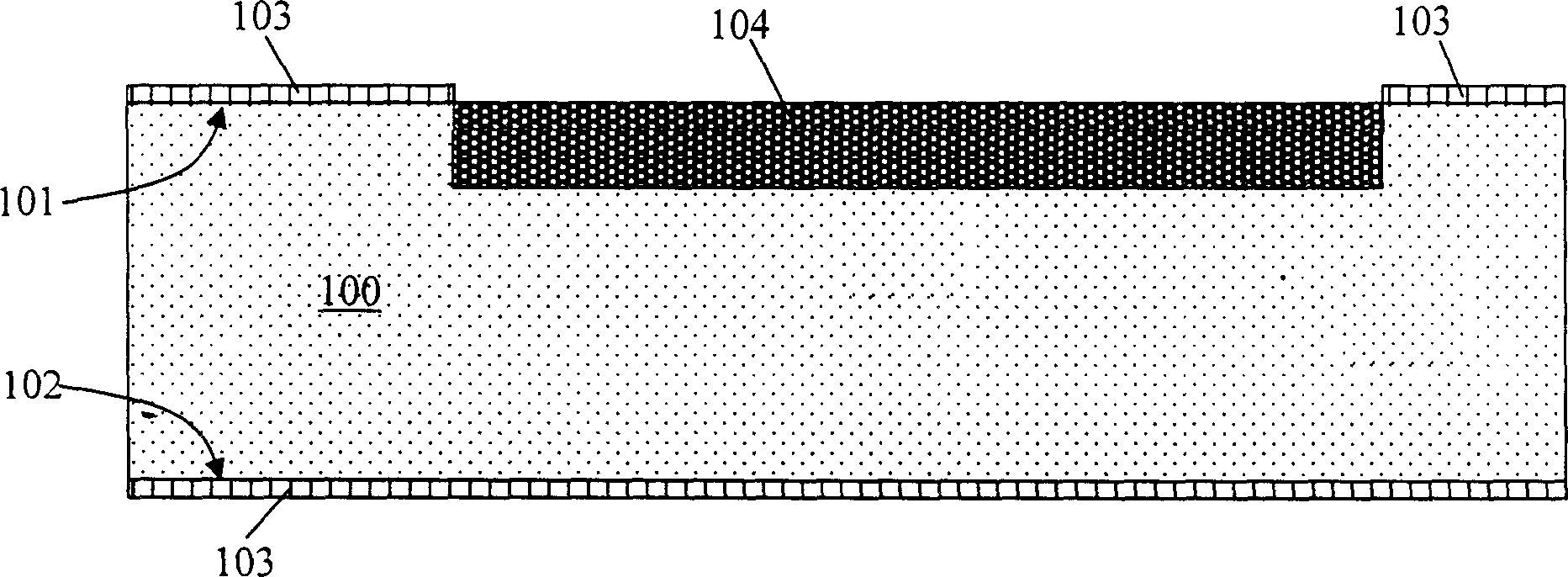

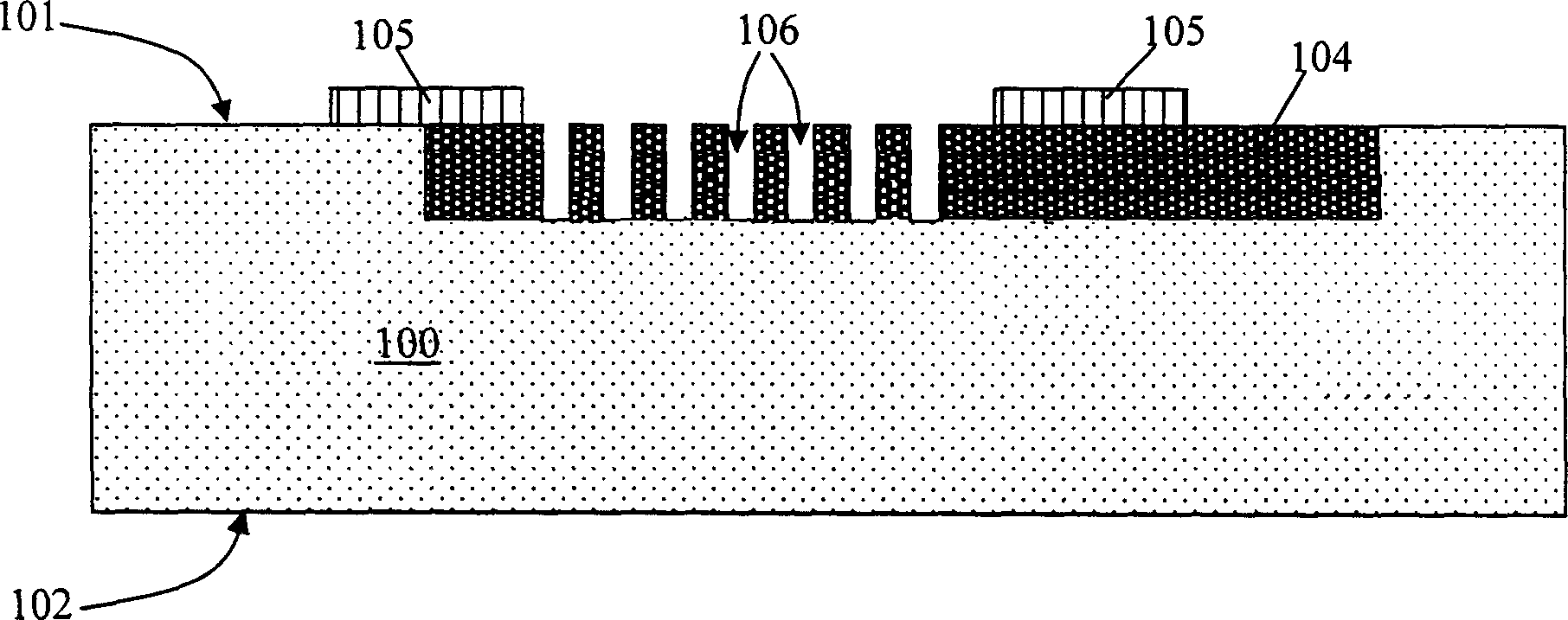

[0040] Such as figure 2 As shown, a silicon substrate 100 is selected first, and the silicon substrate 100 can be an n-type or p+ type silicon wafer. The silicon substrate 100 has an upper surface 101 and a lower surface 102. In one embodiment, the thickness of the silicon substrate 100 is 400 micrometers, but it can be understood that those skilled in the art can adjust the thickness of the silicon substrate 100 according to the required microphone chip size. Silicon substrates 100 with different thicknesses are selected. A layer of high-temperature silicon dioxide is grown on the silicon substrate 100 through a high-temperature oxidation process. Exemplarily, the thickness of the high-temperature silicon dioxide is 1 micron; Af...

Embodiment 2

[0046] Figure 7 ~ Figure 10 Show the preparation process of the silicon microcapacitance microphone chip of the present invention in another embodiment, wherein Figure 10 In this example a good microphone chip was prepared according to the method of the present invention. In the following description of embodiment 2, the same part as embodiment 1 will not be described again, and the difference between embodiment 2 and embodiment 1 will be described emphatically, wherein, in Figure 7 ~ Figure 10 In, the composition identical with embodiment 1 still uses and figure 2 The same reference numerals as in FIG. 5 and different reference numerals are used for parts different from those in Embodiment 1. FIG.

[0047] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the thickness of the doped layer 204 is significantly smaller than figure 2 The thickness of the middle doped layer 104 . It can be known from the following description tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com