Transmission device capable of producing combined motion output

A transmission device and compound motion technology, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problem of high manufacturing precision and heat treatment process requirements of plane guide rails, affecting the movement accuracy of output parts, and easy heating of moving components, etc. problems, to achieve the effect of simple manufacturing process, simple structure, not easy to heat and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

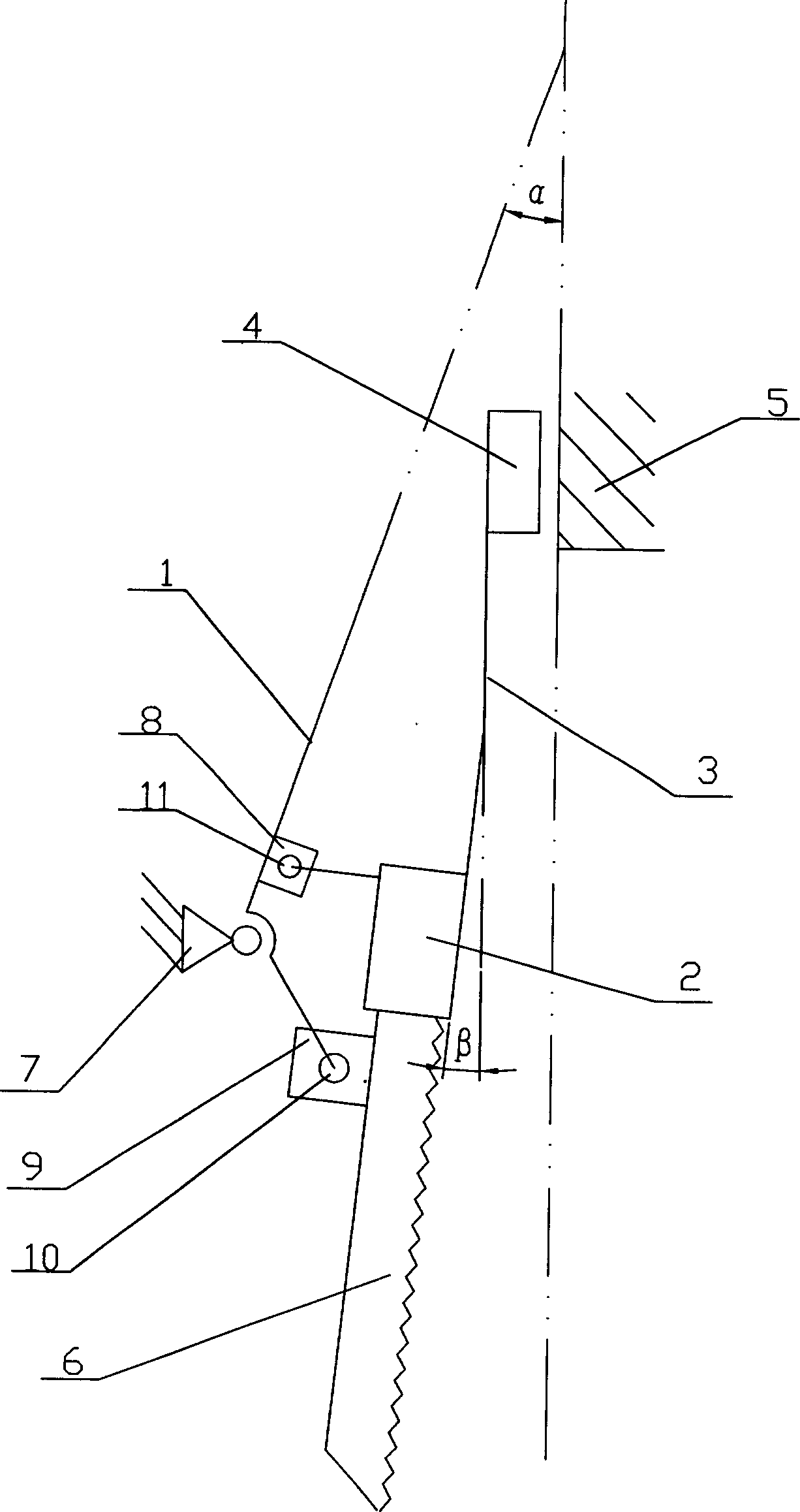

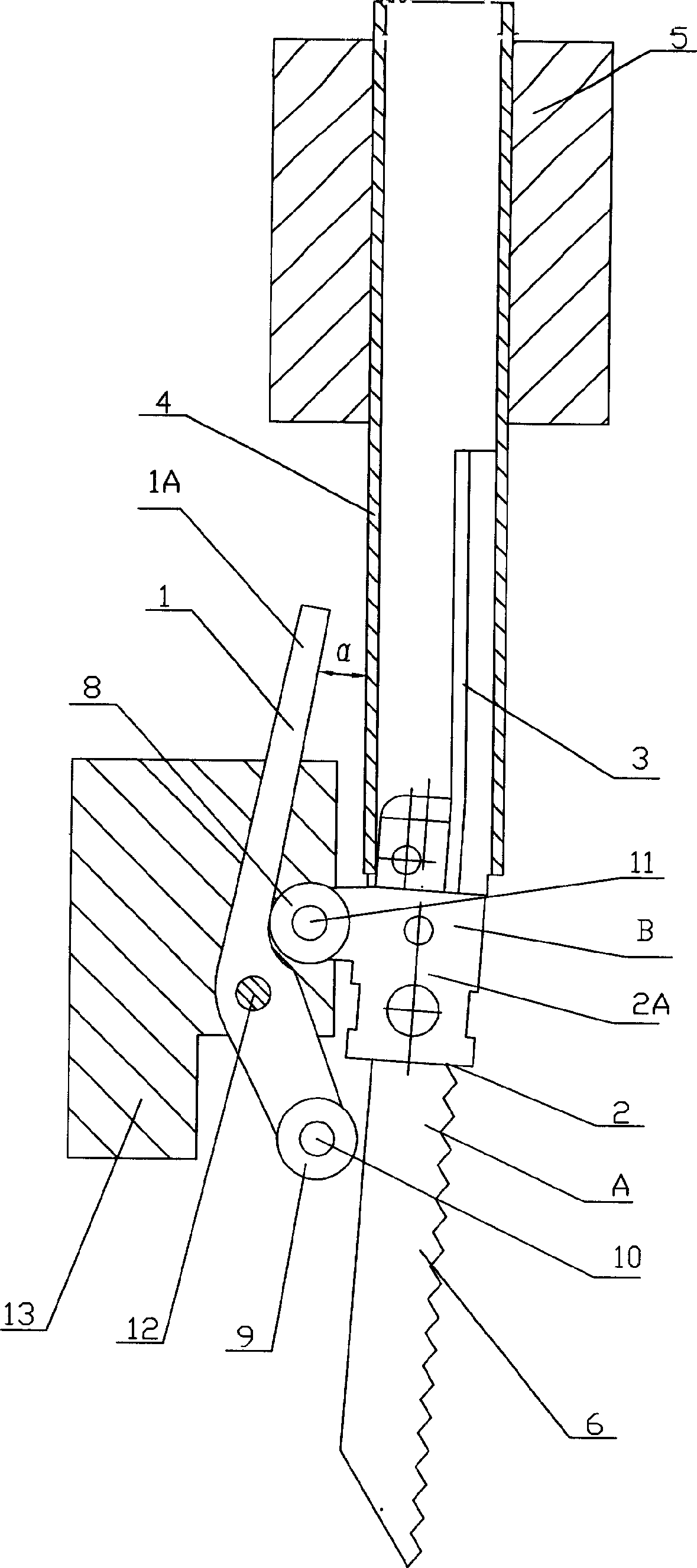

[0021] The principle diagram of the present invention is as figure 2 As shown, the schematic diagram of the structure is shown in image 3 As shown, it includes a swing rod 1, a composite moving part 2, an elastic part 3, and a sliding part 4, wherein the sliding part 4 is installed on the slideway provided by the guide part 5, and the compound moving part 2 is installed on the sliding part through the elastic part 3. On the part 4, the swing rod 1 is hinged on the frame 13 beside the compound moving part 2 through the hinge shaft 12, and one end of the swing rod (1) is in contact with the A end of the compound moving part 2, and the other end is provided with The inclined rod 1A forming an angle α with the moving direction of the sliding member 4 is in contact with the end B of the compound moving member 2 .

[0022] In order to reduce friction, the end B of the composite moving part 2 is in contact with the inclined rod 1A of the swing rod 1 through the roller 8 hinged the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com