Method for testing film residual stress and its layered deep distribution

A technology of residual stress and thin film, which is applied in the field of thin film residual stress measurement, to achieve the effect of novel design, good repeatability and high measurement accuracy

Inactive Publication Date: 2006-06-28

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF0 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that the existing methods for measuring the residual stress of thin films, especially the method for measuring the distribution of residual stress along the depth of the layer, still cannot meet the needs of carrying out relevant research.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

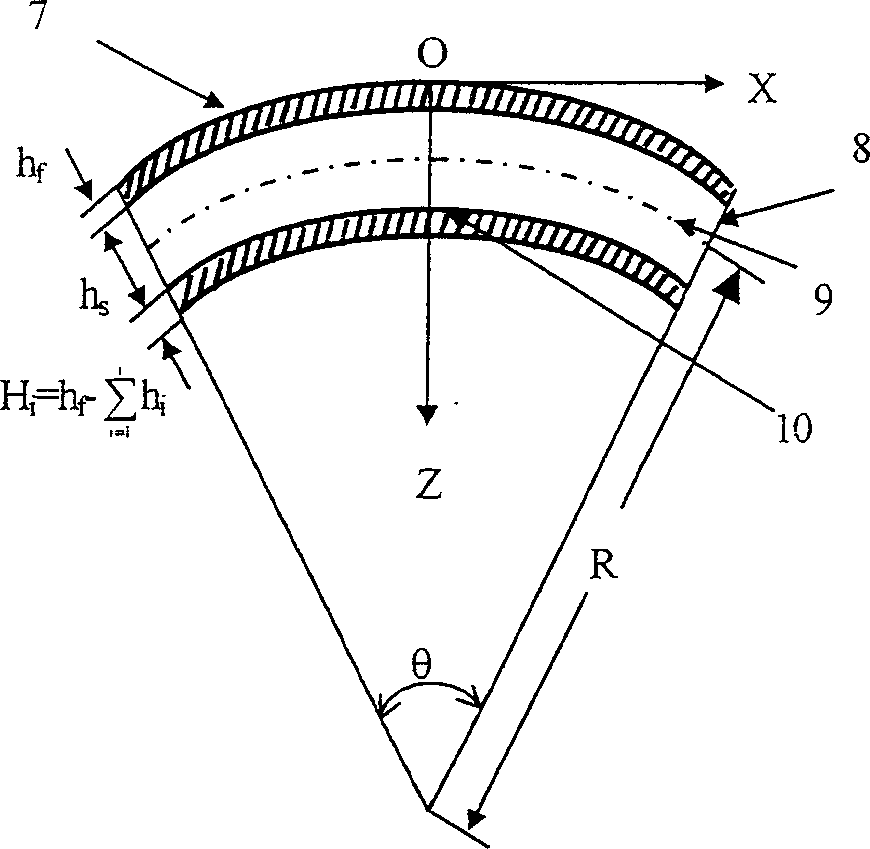

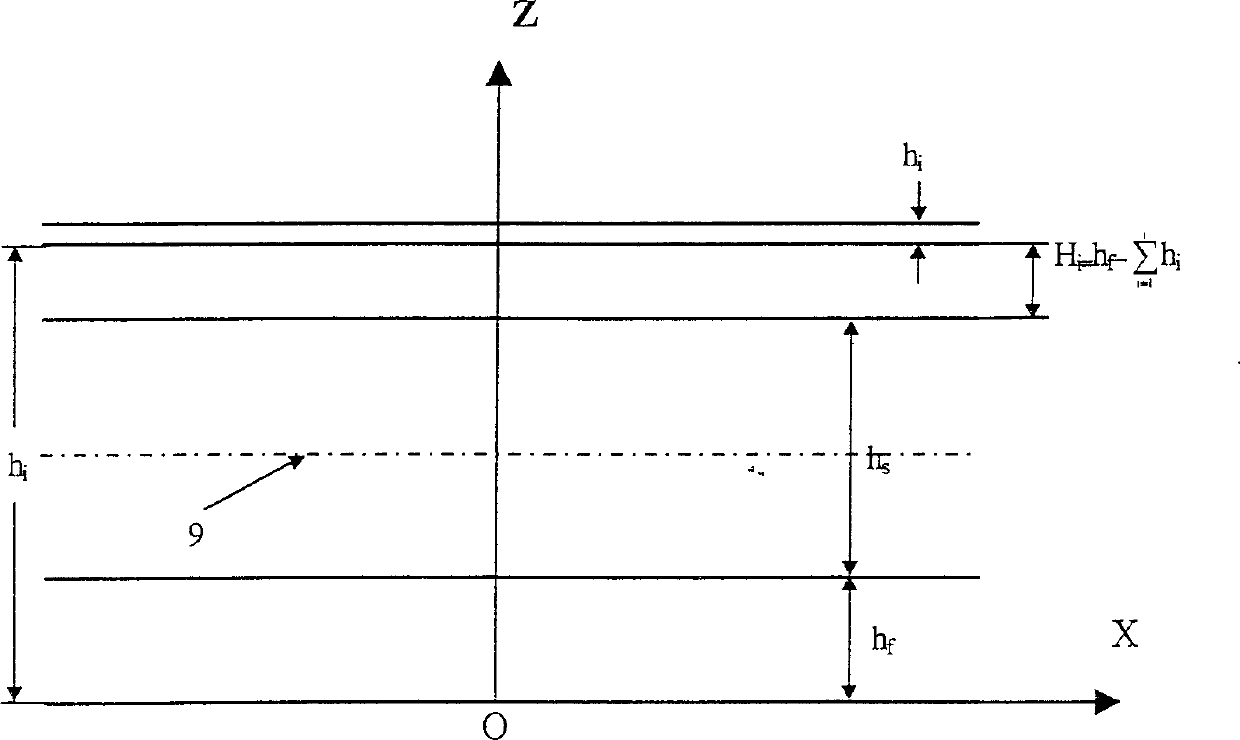

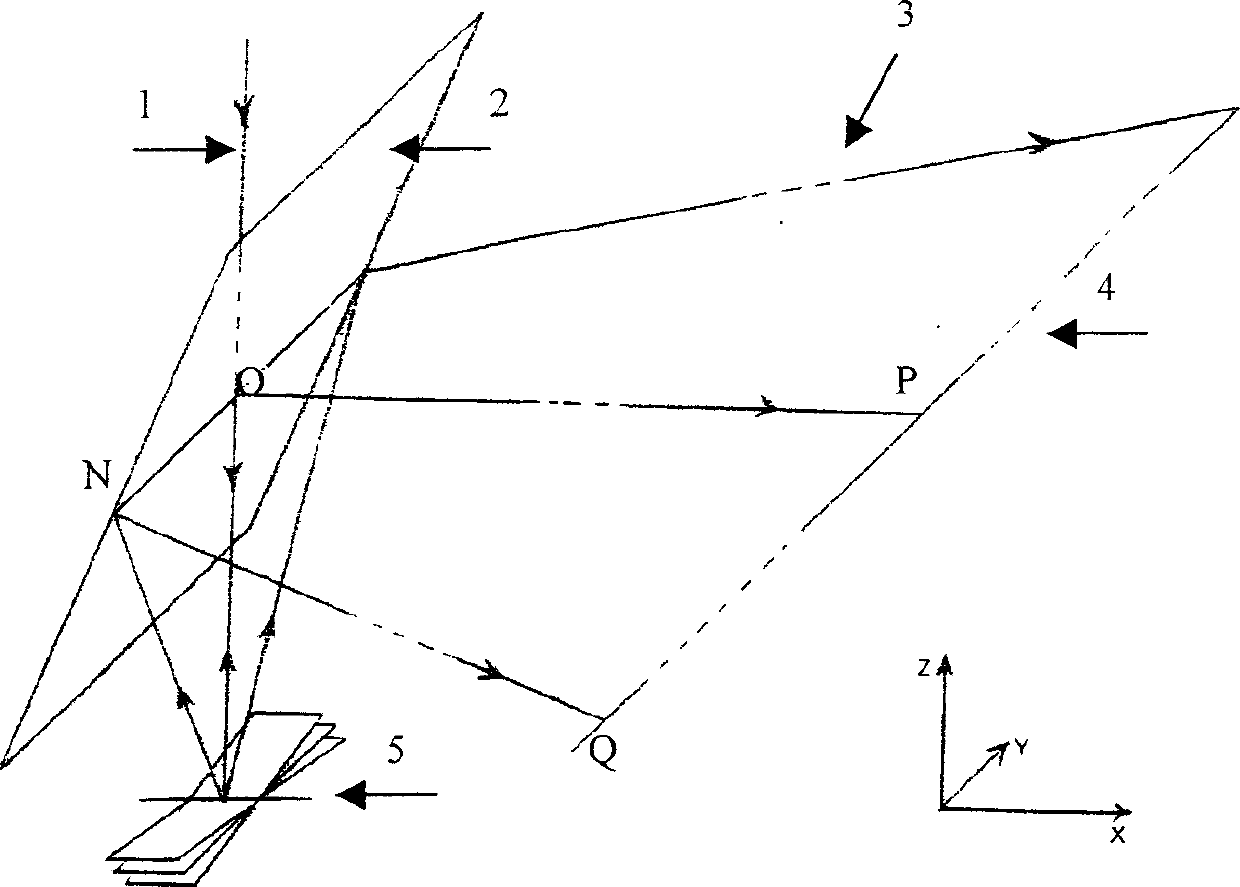

A method for testing film residual stress and its distribution along layer depth includes calculating test sample curvity radius by utilizing relation slope obtained from linear relation of test sample movement distance to distance moved by silicon light cell in following with light beam deflection; applying chemical manner to peel off film layer by layer for solving out equivalent variable R1 of test sample curvity radius before and after each pooling ¿C off; substituting said variable, base plate elastic constant E and v, base plate thickness h and thickness of each pooling ¿C off in a formula to obtain residual stress on each layer of film.

Description

Technical field The invention relates to the measurement technology of the residual stress of the film, in particular to propose a method of using an optical lever system to measure the change in the radius of curvature of a strip-shaped test piece caused by the stripping of the film, thereby calculating the residual stress of the film and its distribution along the layer depth Methods. Background technique Thin films are widely used in modern science and technology. For example, metal materials often use ceramic films with excellent tribological properties and corrosion resistance as protective films. Such films can be prepared using physical vapor deposition (PVD). The as-deposited film generally has a residual compressive stress with an average value of up to several GPa or even a few GPa, and its value in the thickness direction may vary greatly. The residual compressive stress not only directly affects the membrane-base bonding strength, but also has a great influence on th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/17G06F17/11

Inventor 孙超赵升升华伟刚宫骏杜昊王启民李家宝

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com