CT bulb tube oil-duct temperature wireless monitoring system

A wireless monitoring and ball tube technology, applied in temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of not adapting to the use environment, unable to send out alarms from the ball tube, unable to detect oil circuit failures, etc., to achieve observation Intuitive and convenient, avoid temperature rise, avoid damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

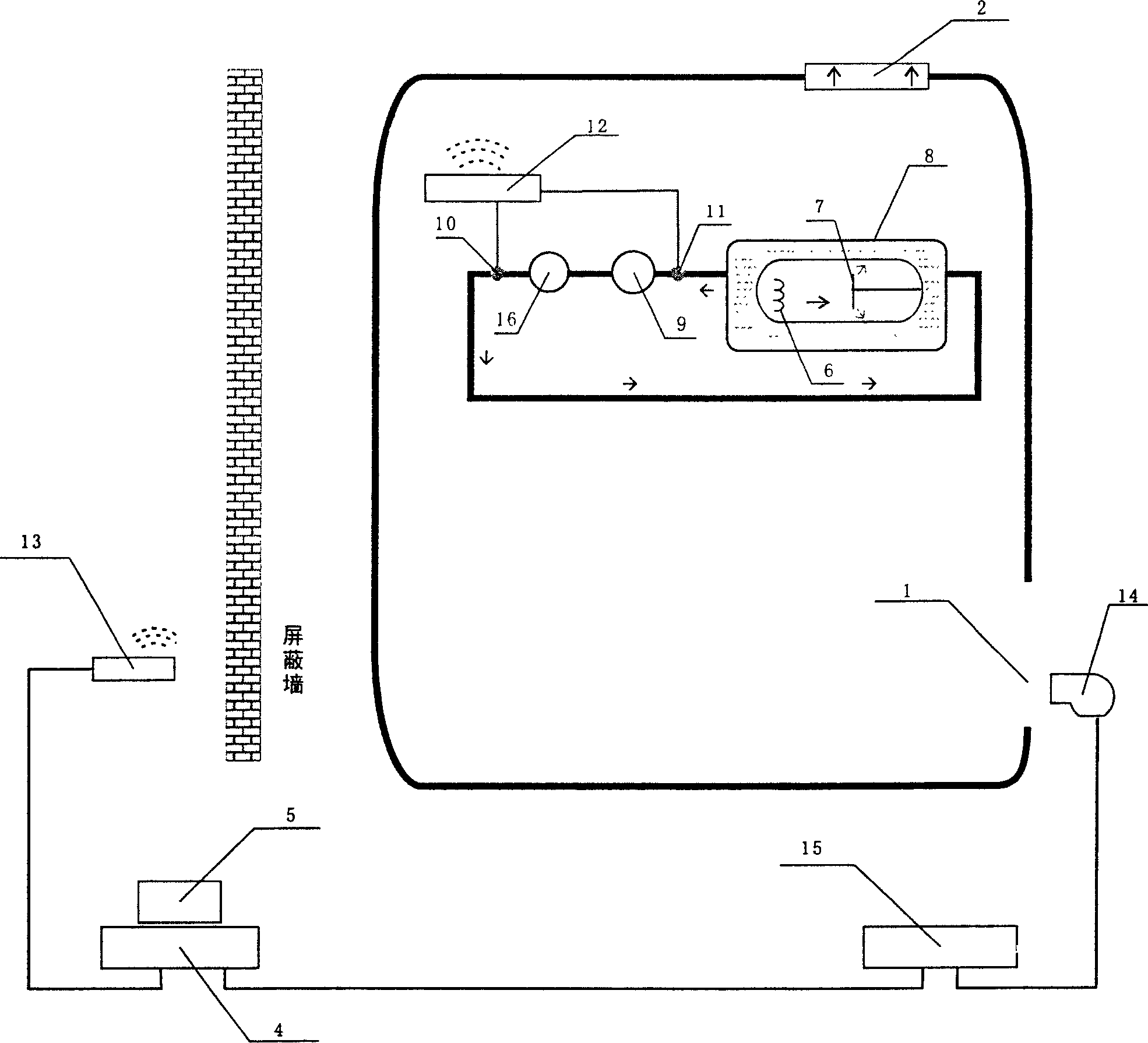

[0019] See the accompanying drawings: a wireless monitoring system for CT tube oil circuit temperature, including a frame with air inlet 1 and air outlet 2, a tube 3 installed in the frame, a computer 4 connected to the CT, and a computer connected to the computer. The display 5, the ball tube includes a heating filament 6 and a heavy metal target surface 7 sealed in the tube shell, cooling oil is arranged outside the tube shell, and the cooling oil circulates along the loop pipeline 8, and the loop pipeline is close to the tube shell An oil pump 9 is arranged at the oil pump, and a fan 16 is arranged at the return pipe at the rear of the oil pump. A first temperature sensor 10 is arranged on the return pipe behind the fan, and a second temperature sensor 11 is arranged on the return pipe between the ball tube and the oil pump. Described first temperature sensor 10, second temperature sensor 11 are connected with the wireless transmission processor 12 that transmits temperature...

Embodiment 2

[0025] Referring to accompanying drawing: the air inlet of frame is provided with air cooler 14, and described computer is provided with air cooler control unit, and described air cooler control unit 15 is connected with monitoring unit, when the first temperature sensor or the second temperature sensor When the temperature is within the set higher temperature value range, the control unit sends a signal to start the cooling fan.

[0026] Said upper upper temperature limit is lower than said normal upper temperature limit.

[0027] The operating temperature range of the preset air cooler, the air cooler starts when the upper limit is exceeded, and the cold air is sent into the rack to accelerate the heat exchange efficiency of the tube, and the air cooler stops operating when it is lower than the lower limit. The upper limit of the operating temperature range of the cooling fan is lower than the normal temperature upper limit, and the bulb tube is cooled in advance.

[0028] ...

Embodiment 3

[0030] The computer is connected with a voice reminding device, and the voice reminding device is connected with the monitoring unit. Voice alarm available.

[0031] The remaining structures and implementation methods of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com