Mobile biomass liquefaction system

A biomass, mobile technology, used in the preparation of liquid hydrocarbon mixtures, oil industry, etc., to achieve compact structure, sufficient contact, and overcome the complex cooling system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

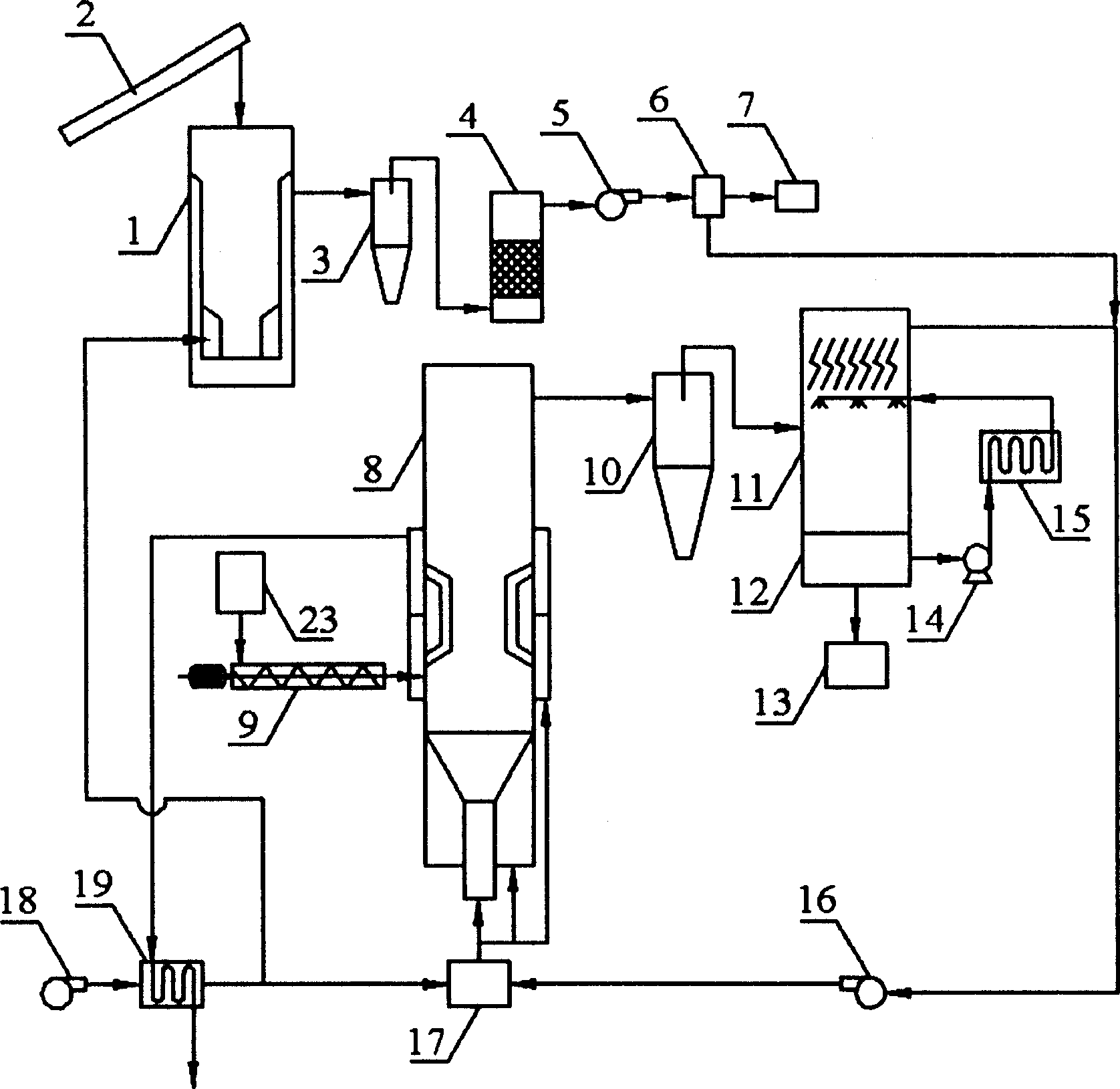

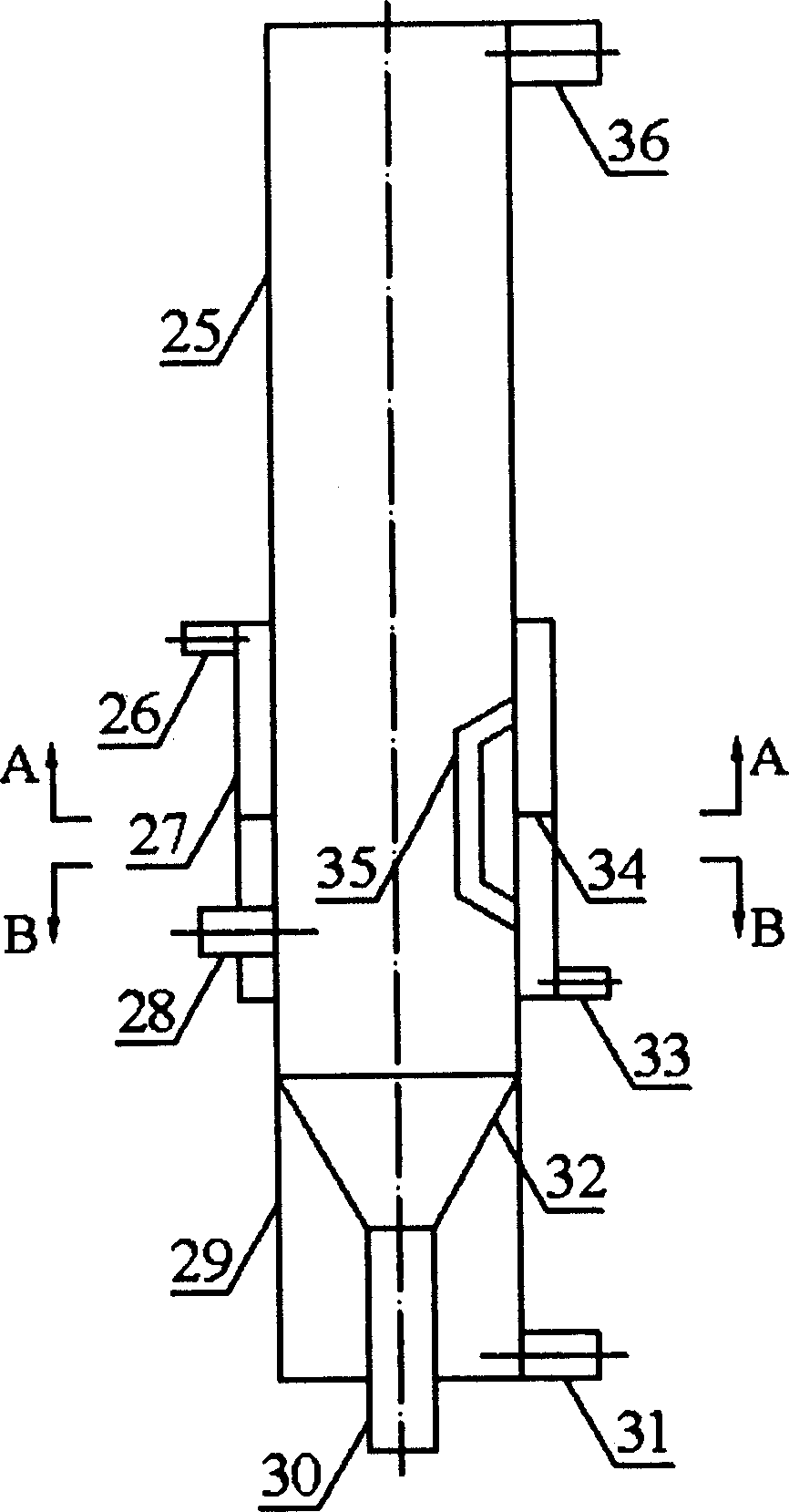

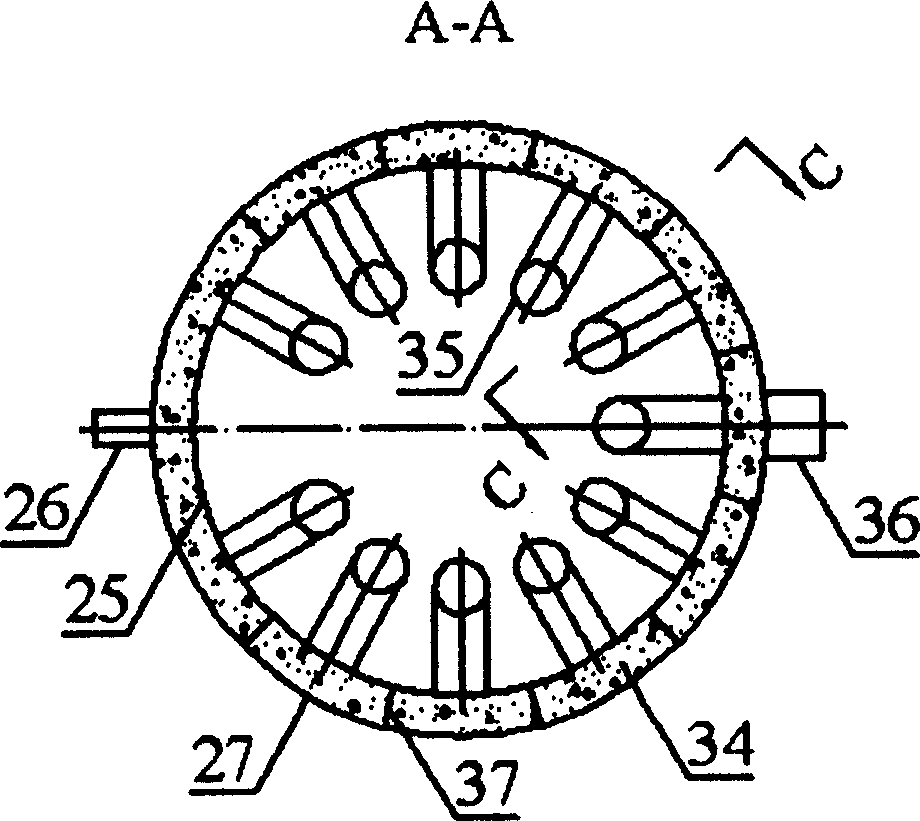

[0027] Depend on figure 1 As shown, the feeder 2, the biomass gasifier 1, the first cyclone separator 3, the tar cracking furnace 4, the fan 5, the gas storage tank 6 and the gas generator set 7 are connected in sequence, and the feed bin 23 and the screw feeder 9. Biomass pyrolysis furnace 8, second cyclone separator 10, cooling tower 11, liquid tank 12 and oil tank 13 are connected in sequence, liquid tank 12 is connected with heat exchanger 15 through circulation pump 14, heat exchanger 15 is connected with cooling The towers 11 are connected, the cooling tower 11 and the gas storage tank 6 are connected to the pre-combustion chamber 17 through the circulation fan 16, the air preheater 19 is connected to the pre-combustion chamber 17, the pre-combustion chamber 17 is connected to the biomass pyrolysis furnace 8, and the biomass pyrolysis furnace 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com